Technical data

7

96

Manual – Gear Units and Gearmotors

Starting frequency (→ GM, → MM)

Project Planning for AC Motors

7.6 Starting frequency (→ GM, → MM)

A motor is usually rated according to its thermal loading. In many applications the motor

is started only once (S1 = continuous running duty = 100 % cdf). The power demand

calculated from the load torque of the driven machine is the same as the rated motor

power.

High starting

frequency

Many applications call for a high starting frequency at low counter-torque, such as in

travel drives. In this case, it is not the power demand that is the decisive factor in deter-

mining the size of the motor, but rather the number of times the motor has to start up.

Frequent starting means the high starting current flows every time, leading to dispropor-

tionate heating of the motor. The windings become overheated if the heat absorbed is

greater than the heat dissipated by the motor ventilation system. The thermal load ca-

pacity of the motor can be increased by selecting a suitable thermal classification or by

means of forced cooling (→ Sec. "Thermal characteristics" on page 93).

No-load starting

frequency Z

0

SEW-EURODRIVE specifies the permitted starting frequency of a motor as the no-load

starting frequency Z

0

at 50 % cdf. This value indicates the number of times per hour that

the motor can accelerate the mass moment of inertia of its rotor up to speed without

counter-torque at 50 % cdf. If an additional mass moment of inertia has to be accelerat-

ed or if an additional load torque occurs, the starting time of the motor will increase.

Increased current flows during this acceleration time. This means the motor is subjected

to increased thermal load and the permitted starting frequency is reduced.

Permitted

starting

frequency of the

motor

You can determine the permitted starting frequency Z of the motor in cycles/hour [1/h]

using the following formula:

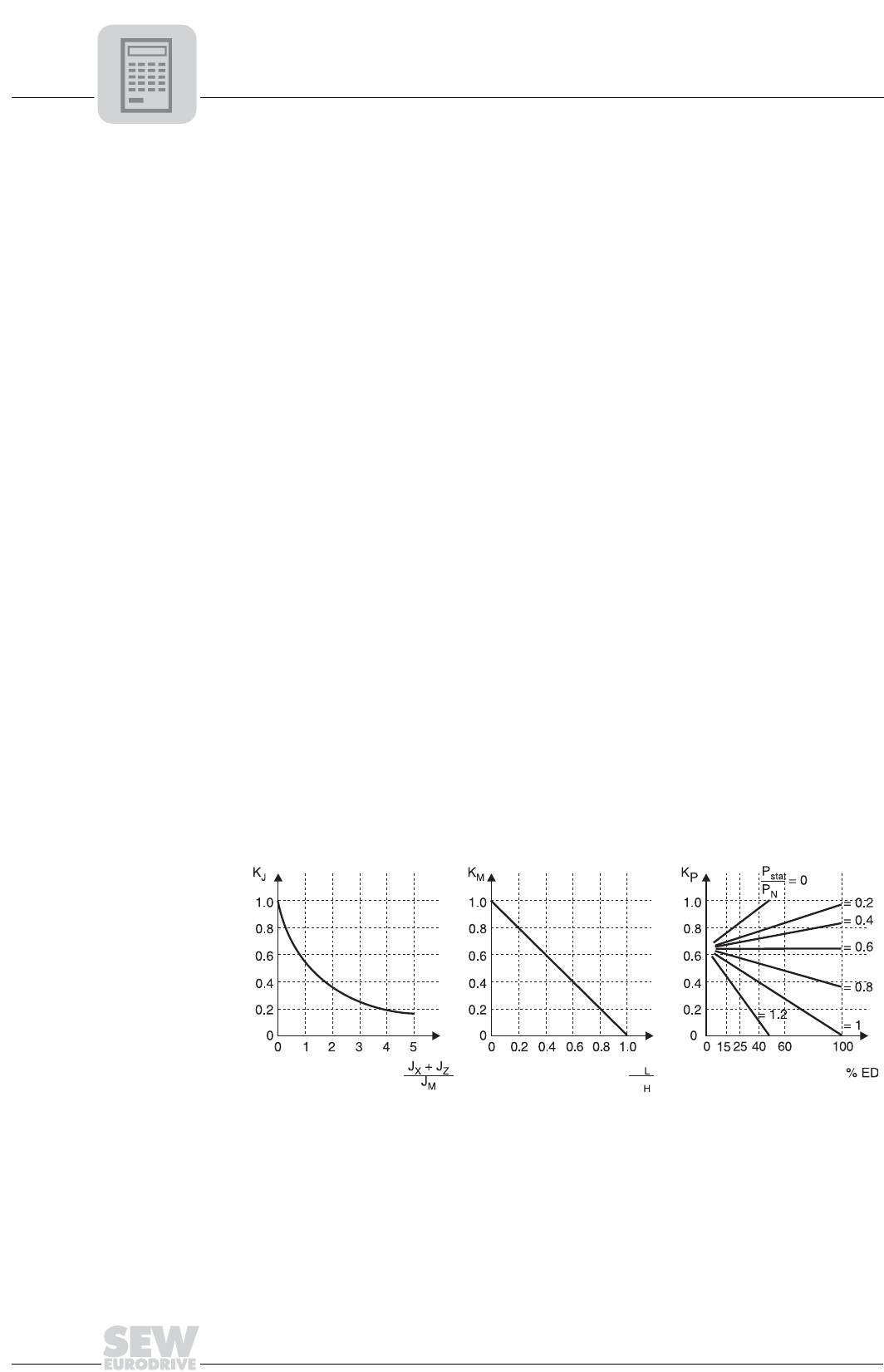

You can determine the factors K

J

, K

M

and K

P

using the following diagrams:

Z = Z

0

• K

J

• K

M

• K

P

Depending on the additional

moment of inertia

Depending on the counter-torque

at startup

Depending on the static power

and the cyclic duration factor (cdf)

00628BUS

Figure 42: Dependency of the starting frequency

J

X

=

Total of all external mass moments of

inertia in relation to the motor axis

T

H

= Acceleration torque motor

J

Z

= Mass moment of inertia flywheel fan P

stat

=

Power requirement after start-up (static

power)

J

M

= Mass moment of inertia of the motor P

N

= Rated motor power

T

L

= Load-torque during startup %cdf = cyclic duration factor

T

T