Technical data

7

88

Manual – Gear Units and Gearmotors

Circuit breakers and protective equipment

Project Planning for AC Motors

Motor protection Selecting the correct protection device is a significant factor in determining the opera-

tional reliability of the motor. We distinguish between protection devices that are current-

dependent and those that depend on the motor temperature. Current-dependent

protection devices include fuses or motor circuit breakers. Temperature dependent

protection devices are PTC thermistors or bimetallic switches (thermostats) in the

winding. PTC thermistors or bimetallic switches respond when the maximum permitted

winding temperature is reached. Their advantage is that temperatures are measured

right where they occur.

Motor circuit

breakers

Motor circuit breakers offer adequate protection against overload in standard operation

with a low starting frequency, brief start-ups and starting currents that are not excessive.

The motor circuit breaker is set to the rated motor current.

Motor circuit breakers are not adequate as the sole means of protection given switching

operation with a high starting frequency (> 60 1/h) and for high inertia starting. In these

cases, we recommend you use positive temperature coefficient (PTC) thermistors TF in

addition.

PTC thermistor Three positive temperature coefficient (PTC) thermistors TF (PTC, characteristic curve

according to DIN 44080) are connected in series in the motor and connected from the

terminal box to the TF/TH input of the inverter or to a trip switch in the control cabinet.

Motor protection with positive temperature coefficient (PTC) thermistors TF provide

comprehensive protection against thermal overload. Motors protected in this way can be

used for high inertia starting, switching and braking operation as well as with fluctuating

mains power supply. A motor circuit breaker is usually installed in addition to the TF.

SEW-EURODRIVE recommends always using motors equipped with TF for inverter op-

eration.

Bimetallic switch Three bimetallic switches TH, connected in series in the motor, are looped directly into

the motor monitoring circuit from the terminal box.

Fuses Fuses do not protect the motor from overload. Their only purpose is short-circuit

protection.

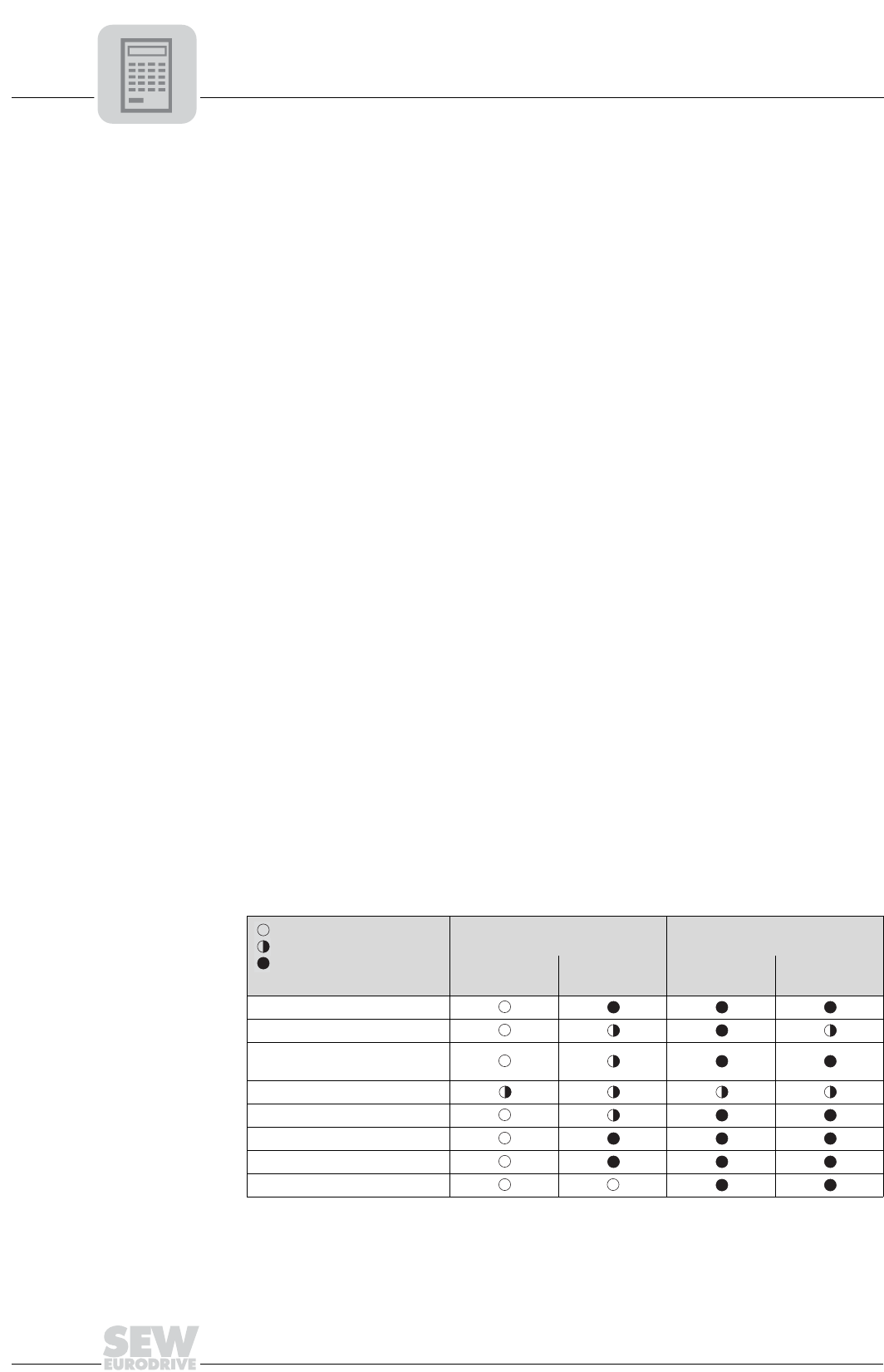

The following table provides an overview of the various protection devices used for

various causes.

MOVIMOT

®

protection devices

• MOVIMOT

®

integrate protective equipment to prevent thermal damage.

• No other external devices are required for motor protection.

= no protection

= limited protection

= comprehensive

protection

Current dependent

protection device

Temperature dependent

protection device

Fuse

Protective

circuit breaker

PTC

thermistor (TF)

Bimetallic

switch (TH)

Over-currents up to 200 % I

N

High inertia starting, reversal

Switching operation up to Z =

30 1/h

Stalling

Single phasing

Voltage deviation

Frequency deviation

Insufficient motor cooling