Technical data

Manual – Gear Units and Gearmotors

81

6

Input shaft assembly AD (→ GK)

Project Planning for Components on the Input Side

Centering

shoulder AD../ZR

The input shaft assembly can be configured with a centering shoulder as an option. In

this way, a customer’s application can be attached to the cover centrally in relation to

the input shaft side.

Backstop AD../RS The input shaft assembly can be supplied with a backstop if the application only requires

one permitted direction of rotation. Backstops with centrifugal lift-off sprags are used.

The advantage of this design is that the sprags move around inside the backstop without

making contact above a certain speed (lift-off speed). This means backstops operate

wear-free, maintenance-free, without losses, and they are suited for high speeds.

Dimensions:

The backstop is completely integrated in the cover. This means there is no difference in

dimensions between an input shaft assembly with or without backstop (see dimension

sheets in the "Input shaft assembly AD" section).

Locking torques:

Specify output direction of rotation in your order:

When you order a gear unit with input shaft assembly and backstop, it is necessary to

indicate the direction of rotation of the output shaft/output side. The direction of rotation

is given looking onto the output shaft/output side of the gear unit. For drives with shaft

ends at sides A and B, the direction of rotation must be specified as looking onto side A.

Check the direction of rotation of the drive before starting up the system to avoid

damage.

Type Maximum locking torque backstop

[lb-in]

Lift-off speed

[rpm]

AD2/RS 795 640

AD3/RS 3010 600

AD4/RS 6200 550

AD5/RS 10600 630

AD6/RS 12800 430

AD7/RS 12800 430

AD8/RS 25300 430

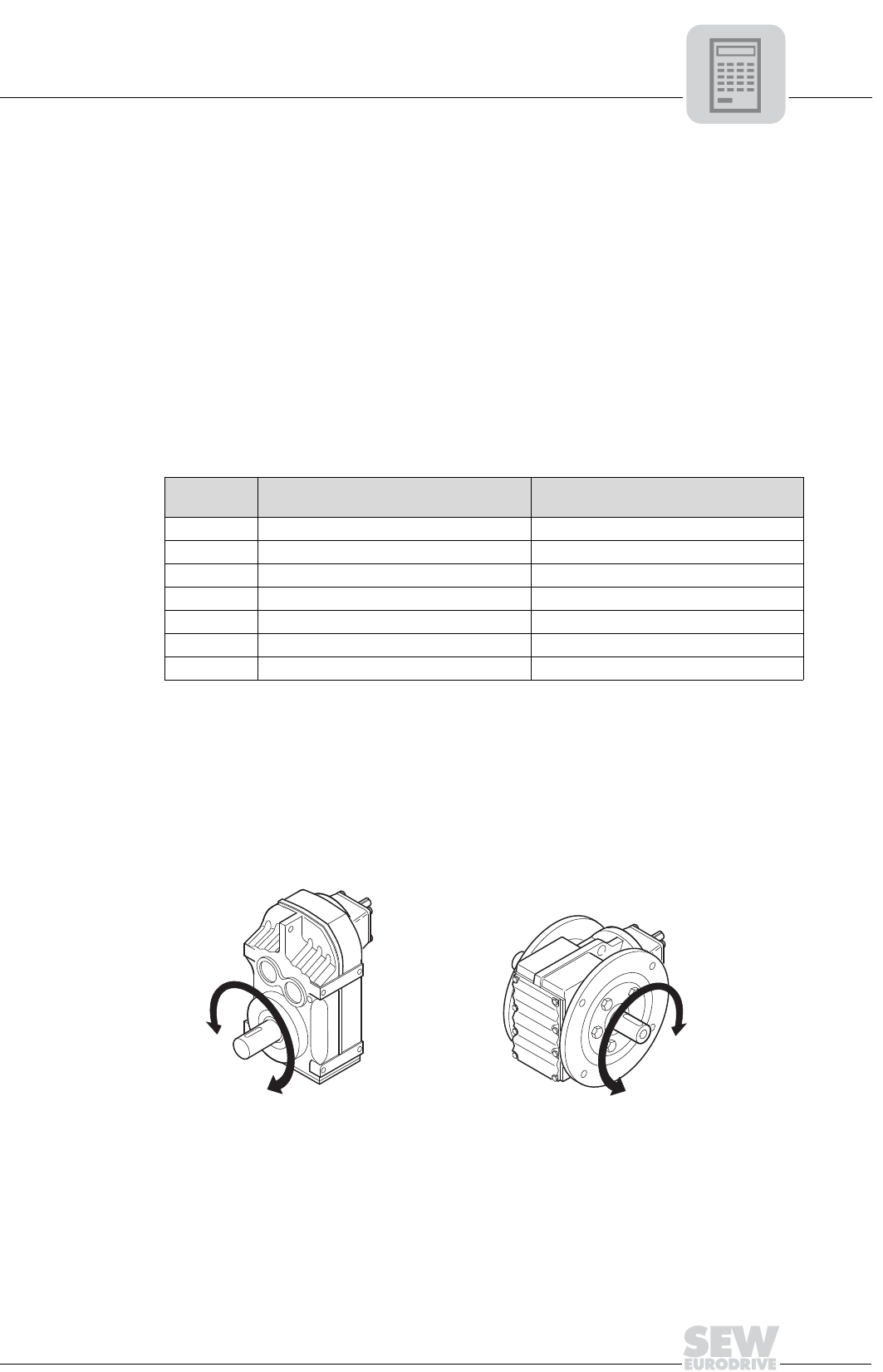

53722AXX

Figure 34: Specify output direction of rotation when ordering

CCW = Counterclock-

wise rotation

CW = Clockwise

rotation

A

B

CCW

CW

CCW

C

W