Technical data

6

78

Manual – Gear Units and Gearmotors

Project planning for helical-bevel gear units on swing base MK (→ GK)

Project Planning for Components on the Input Side

Mechanical

thermal

monitoring

device /MTS

Using a mechanical thermal monitoring device can prevent the operating fluid from

being sprayed into the environment. A switch pin screwed into the coupling releases a

spring-loaded switch pin if the temperature reaches an excessive level. This switch pin

operates a switch by means of which a warning signal can be output or the machine can

be switched off.

Apart from the monitoring device, the centrifugal coupling is equipped with fusible safety

plugs. However, these react considerably later than the monitoring device.

Proximity-type

thermal monitor-

ing device /BTS

Using a contactless thermal monitoring device can prevent the operating fluid from

being sprayed into the environment. The monitoring device consists of three compo-

nents: a switch pin, which is screwed into the coupling and that changes its inductance

if the temperature reaches an excessive level, a switch which detects that the induc-

tance of the switch bolt has changed, and an evaluation unit (speed monitor), which

evaluates the signals from the switch. In turn, a warning signal can be output via the

speed monitor or the machine can be switched off.

The switch pin regenerates itself and is ready for use again once the coupling has

cooled down.

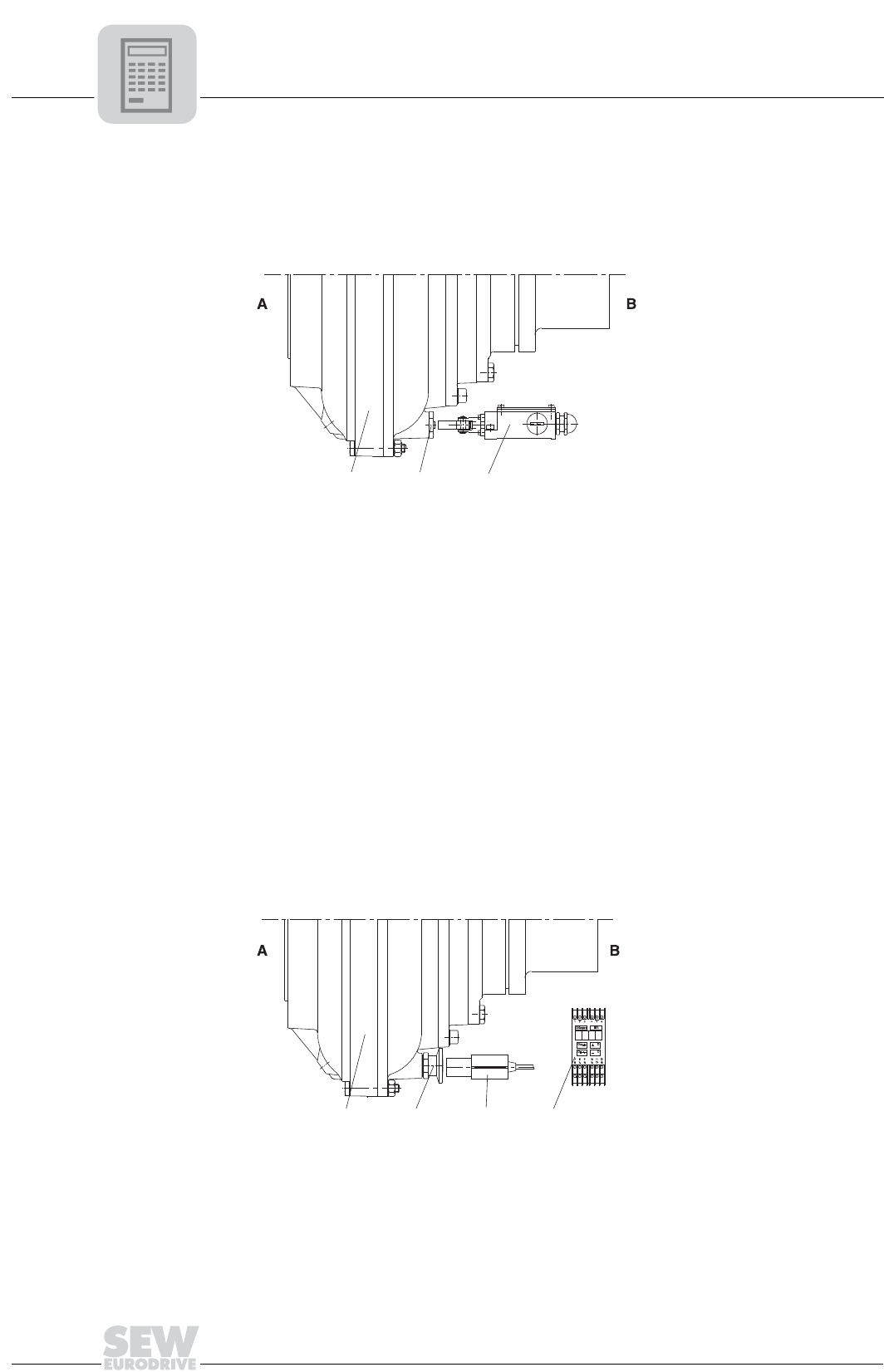

52258AXX

Figure 31: Mechanical thermal monitoring device /MTS

[1] Hydraulic centrifugal coupling

[2] Switch bolt

[3] Switch

[A] Gear unit side

[B] Motor side

[1]

[2] [3]

52259AXX

Figure 32: Proximity-type thermal monitoring device /BTS

[1] Hydraulic centrifugal coupling

[2] Switch bolt

[3] Switch

[4] Speed monitor

[A] Gear unit side

[B] Motor side

[1] [2] [3] [4]