Technical data

Manual – Gear Units and Gearmotors

71

6

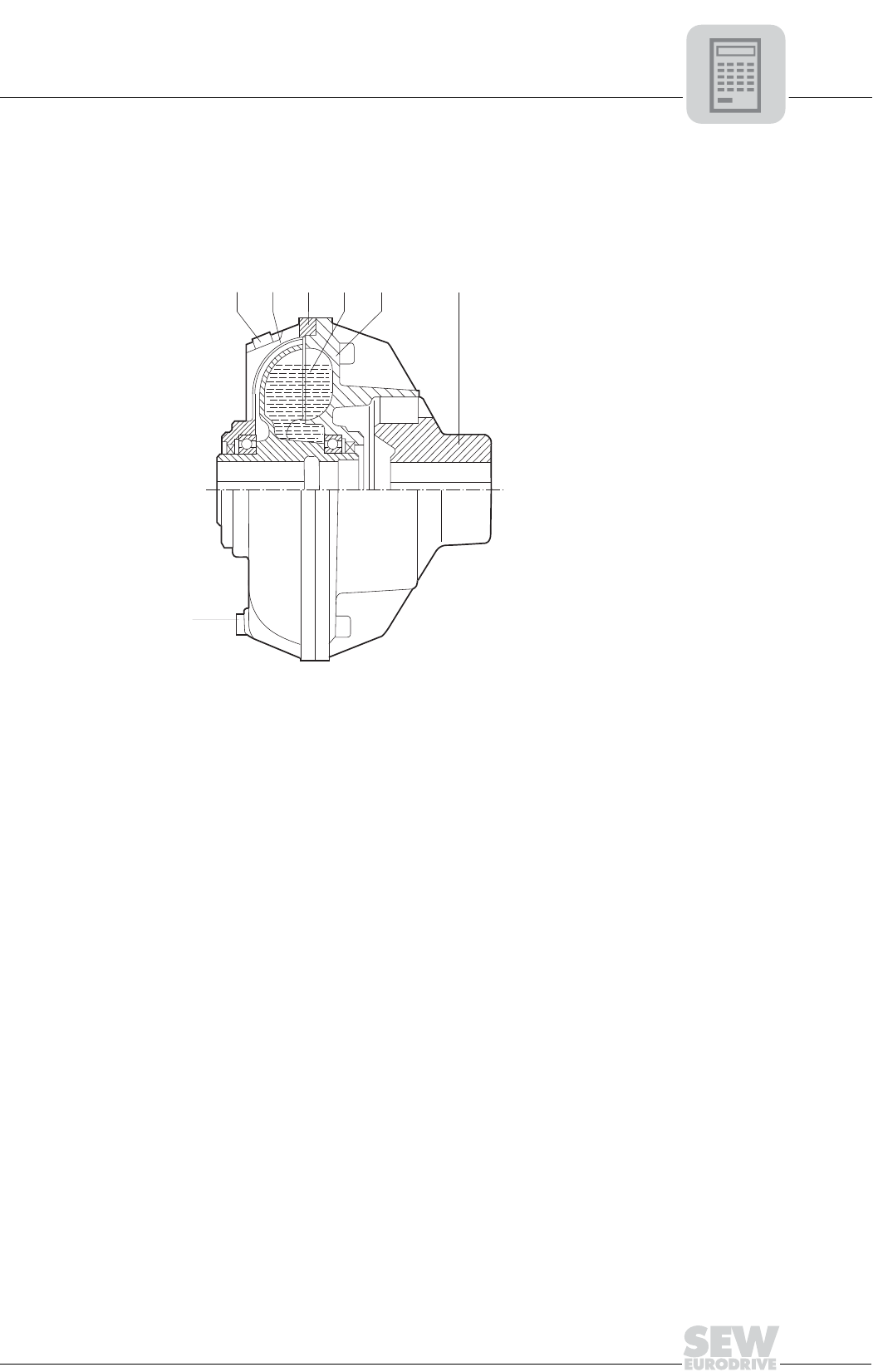

Adapter with hydraulic centrifugal coupling AT (→ GK)

Project Planning for Components on the Input Side

Centrifugal

coupling

The centrifugal coupling used is a hydrodynamic coupling that operates according to the

Föttinger principle. The coupling is filled with oil and consists of a pump wheel (motor

side) and a turbine wheel (gear unit side). The pump wheel converts the input mechan-

ical energy into fluid energy and the turbine wheel converts this energy back into

mechanical energy.

The power which the coupling can transmit significantly depends on the speed. A

distinction is made between startup phase and stationary operation. During the startup

phase, the motor starts without load until the coupling transmits torque. The machine is

accelerated slowly and smoothly during this phase. Once stationary operation is

reached, there will be an operating slip between motor and gear unit caused by the

operating principle of the coupling. Only the load torque of the system is required from

the motor. Load peaks are attenuated by the coupling.

The hydraulic centrifugal coupling is equipped with fusible safety plugs that allow the

operating fluid to be evacuated in the event of excessive temperature (severe overload,

blockage). In this way the coupling and system are protected from damage.

52251AXX

Figure 25: Centrifugal coupling

[1] Filling plug

[2] Turbine wheel

[3] Coupling half

[4] Operating fluid (hydraulic oil)

[5] Pump wheel

[6] Flexible connecting coupling

[7] Fusible safety plug

[A] Gear unit side

[B] Motor side

[1]

A

B

[2]

[7]

[3] [4] [5] [6]