Technical data

Manual – Gear Units and Gearmotors

45

5

Efficiency of gear units

Project Planning for Gear Units

Run-in phase The tooth flanks of new helical-worm and Spiroplan

®

gear units are not yet completely

smooth. That fact makes for a greater friction angle and less efficiency than during later

operation. This effect intensifies with increasing gear unit ratio. Subtract the following

values from the listed efficiency during the run-in phase:

The run-in phase usually lasts 48 hours. Helical-worm and Spiroplan

®

gear units

achieve their listed rated efficiency values when:

• the gear unit has been completely run in,

• the gear unit has reached nominal operating temperature,

• the recommended lubricant has been filled in and

• the gear unit is operating in the rated load range.

Churning losses In certain gear unit mounting positions (→ Sec. "Mounting positions and important order

information"), the first gearing stage is completely immersed in the lubricant. Consider-

able churning losses occur in larger gear units and high circumferential velocity of the

input stage. Contact SEW-EURODRIVE if you wish to use gear units of this type.

If possible, use mounting position M1 for R, K and S gear units to keep the churning

losses low.

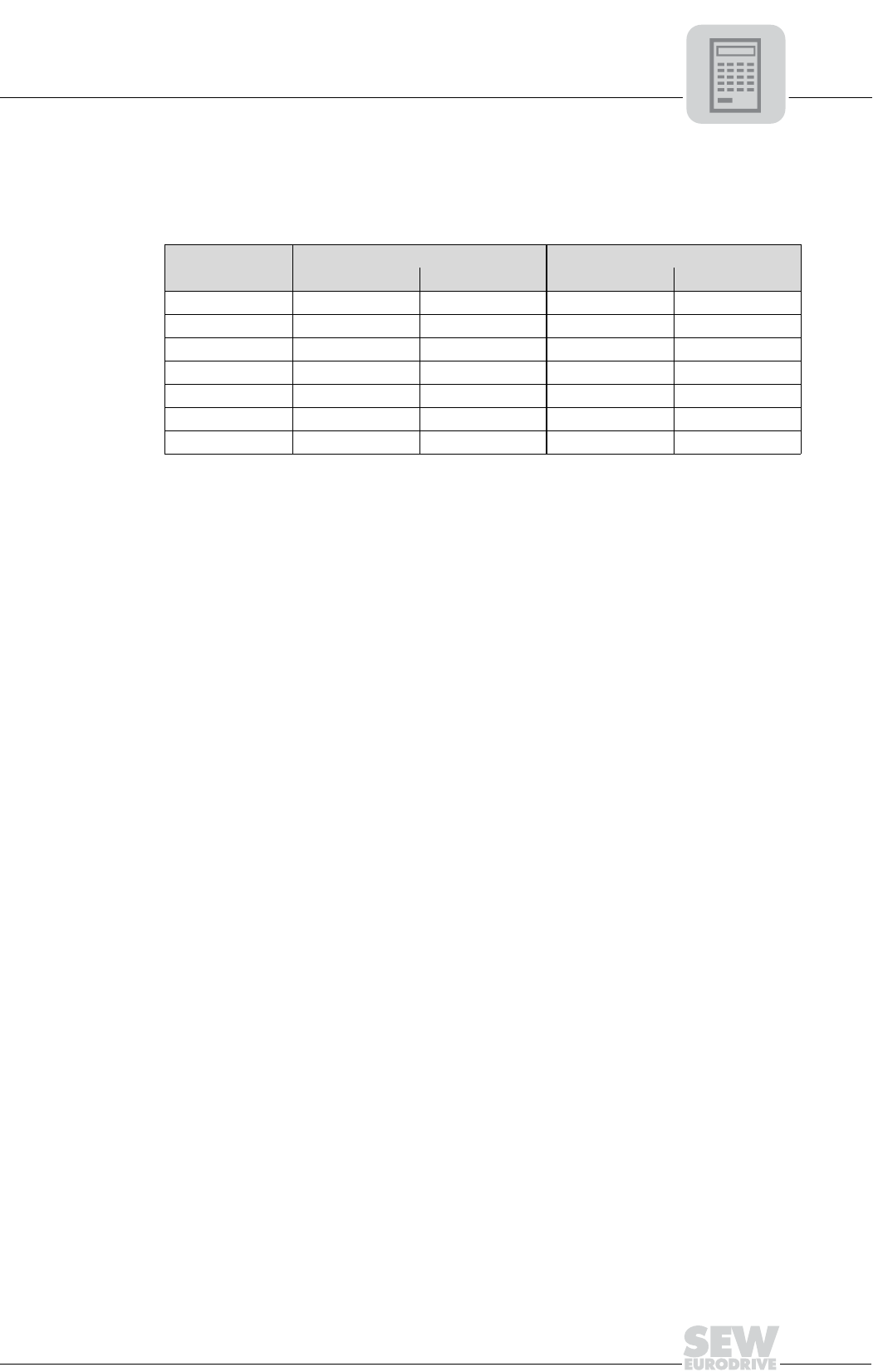

Worm Spiroplan

®

i range η reduction i range η reduction

1 start approx. 50 ... 280 approx. 12 % approx. 40 ... 75 approx. 15 %

2 start approx. 20 ... 75 approx. 6 % approx. 20 ... 30 approx. 10 %

3 start approx. 20 ... 90 approx. 3 % approx. 15 approx. 8 %

4 start - - approx. 10 approx. 8 %

5 start approx. 6 ... 25 approx. 3 % approx. 8 approx. 5 %

6 start approx. 7 ... 25 approx. 2 % - -

7 start - - approx. 6 approx. 3 %