Technical data

10

192

Manual – Gear Units and Gearmotors

Installation/removal of gear units with hollow shafts and keys

Design and Operating Notes

10.2 Installation/removal of gear units with hollow shafts and keys

Installation SEW-EURODRIVE recommends two variants for installation of gear units with hollow

shaft and key onto the input shaft of the driven machine (= customer shaft):

1. Use the fastening parts supplied for installation.

2. Use the optional installation/removal tool for installation.

1) Supplied

fastening parts

The following fastening parts are supplied as standard:

• Retaining screw with washer (2)

• Circlip (3)

Note the following points concerning the customer shaft:

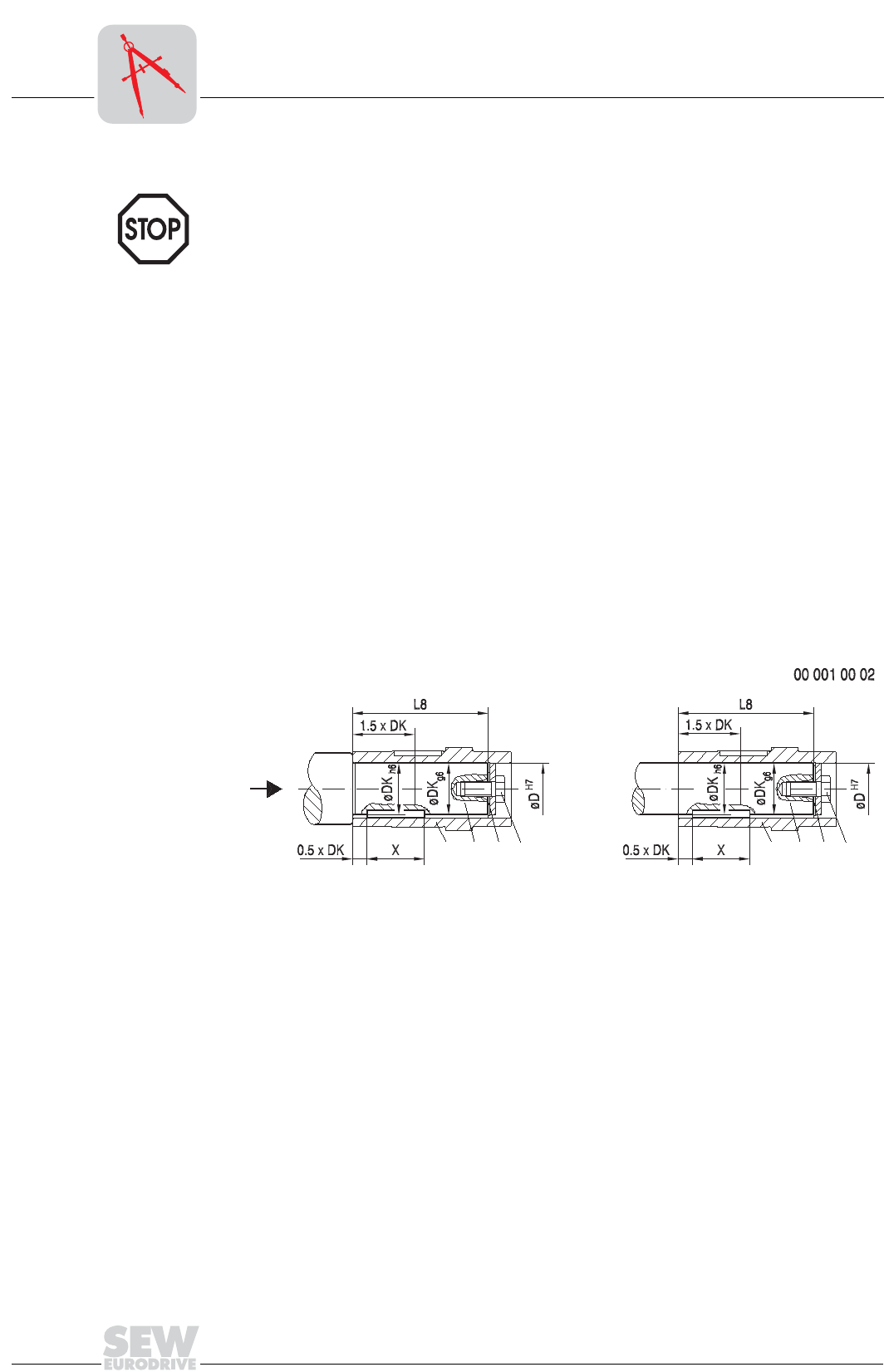

• The installation length of the customer shaft with contact shoulder (A) must be L8 -

1 mm (0.04 in).

• The installation length of the customer shaft without contact shoulder (B) must equal

L8.

• Always use the supplied NOCO

®

fluid for installation. The fluid prevents contact

corrosion and facilitates subsequent removal.

• The keyway dimension X is specified by the customers, but X must > DK.

Figure 97: Customer shaft with contact shoulder (A) and without contact shoulder (B)

(1) Hollow shaft

(2) Retaining screw with washer

(3) Circlip

(4) Customer shaft

[1] [2][3][4]

[1]

[4] [3] [2]

[A]

[B]