Technical data

Manual – Gear Units and Gearmotors

185

10

Lubricants

Design and Operating Notes

10 Design and Operating Notes

10.1 Lubricants

General

information

Unless a special arrangement is made, SEW-EURODRIVE supplies the drives with a

lubricant fill adapted for the specific gear unit and mounting position. The decisive factor

is the mounting position (M1 – M6, → Sec. "Mounting positions and important order

information" in the Gearmotor catalog) specified when ordering the drive. You must

adapt the lubricant fill in case of any subsequent changes made to the mounting position

(→ Lubricant fill quantities).

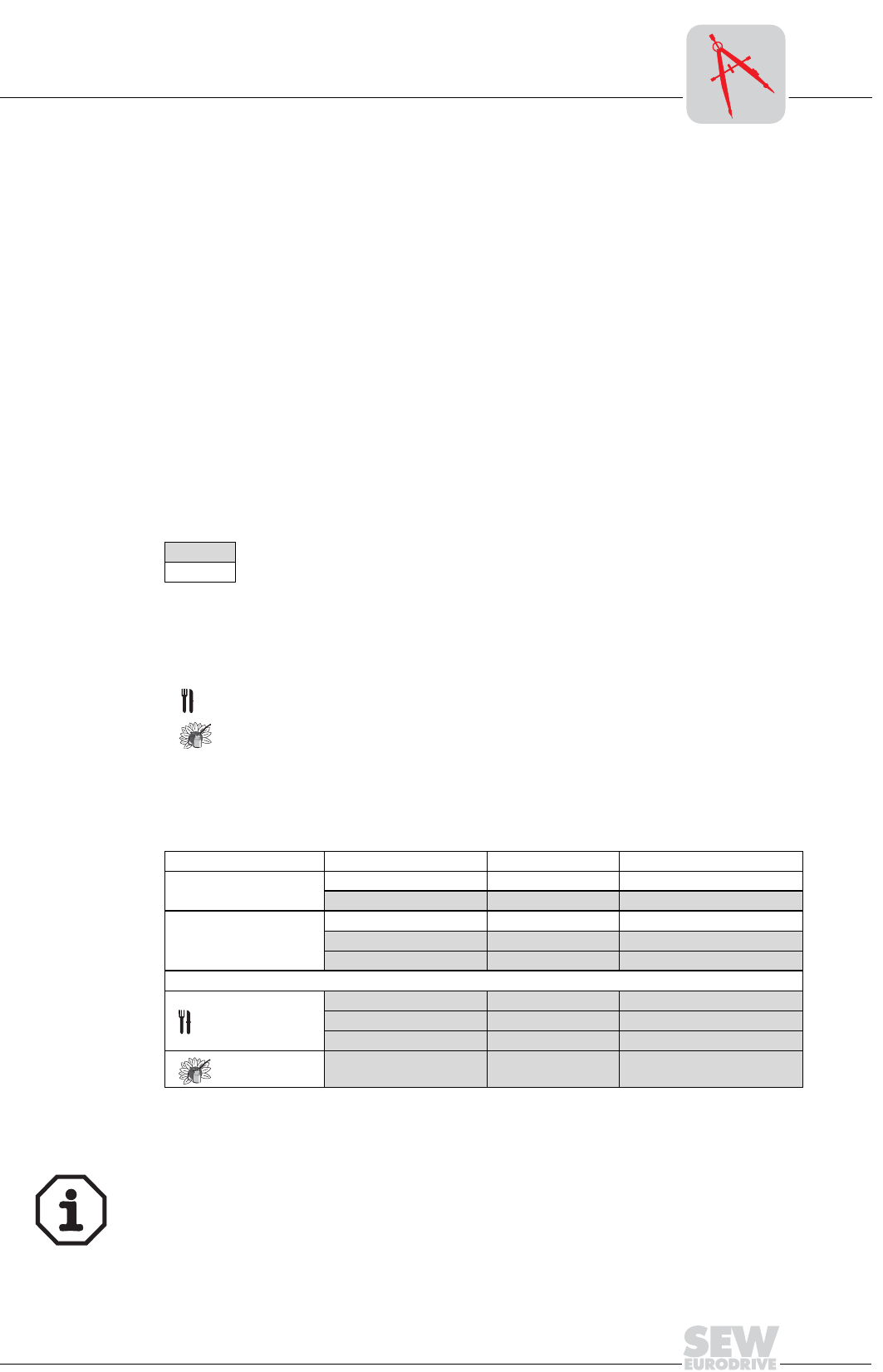

Lubricant table The lubricant table on the following page shows the permitted lubricants for SEW-

EURODRIVE gear units. Please refer to the following legend for the lubricant table.

Legend for the

lubricant table

Abbreviations, meaning of shading and notes:

Anti-friction

bearing greases

The anti-friction bearings in gear units and motors are given a factory-fill with the greas-

es listed below. SEW-EURODRIVE recommends regreasing anti-friction bearings with

a grease fill at the same time as changing the oil or replacing the anti-friction bearings.

CLP = Mineral oil

CLP PG = Polyglycol (W gear units, NSF certified H1)

CLP HC = Synthetic hydrocarbons

E = Ester oil (water hazard class 1 (German regulation))

HCE = Synthetic hydrocarbons + ester oil (NSF certified H1)

HLP = Hydraulic oil

= Synthetic lubricant (= synthetic-based anti-friction bearing grease)

= Mineral lubricant (= mineral-based anti-friction bearing grease)

1) Helical-worm gear units with PG oil: please contact SEW-EURODRIVE.

2) Special lubricant for Spiroplan

®

gear units only

3) SEW-f

B

≥ 1.2 required

4) Pay attention to critical starting behavior at low temperatures!

5) Ambient temperature

Lubricant for the food industry (food grade oil)

Biodegradable oil (lubricant for agriculture, forestry, and fisheries)

Oil

Oil

Ambient temperature Manufacturer Type

Anti-friction bearing in

gear unit

-10 °C ... +60°C ExxonMobil Mobilux EP2

-40 °C ... +80 °C ExxonMobil Mobilith SHC 100

Anti-friction bearing in

motor

1)2)

1) The motor anti-friction bearings are covered on both sides and cannot be regreased.

2) Greases providing equivalent performance are acceptable

-20 °C ... +80 °C ExxonMobil Polyrex EM

+20 °C ... +100 °C Klüber Barrierta L55/2

-40 °C ... +40 °C ExxonMobil Mobilith SHC 100

3)

3) Recommended for continuous operation at ambient temperature below 0°C, example in a cold storage.

Special greases for anti-friction bearings in gear units:

-25 °C ... +80 °C Shell Shell Cassida Grease EPS 2

-35 °C ... +60 °C Klüber Klübersynth UH1 14-151

-15 °C ... +80 °C Klüber Klübersynth UH1 14-222

-20 °C ... +40 °C Klüber Klüberbio M 32-82

Oil

Oil

The following grease quantities are required:

• For high-rpm bearings (gear unit input end): Fill the cavities between the rolling ele-

ments one-third full with grease.

• For low-rpm bearings (in gear units and at gear unit output end): Fill the cavities be-

tween the rolling elements two-thirds full with grease.