Technical data

2

16

Manual – Gear Units and Gearmotors

Corrosion and surface protection

Product Description

Surface

protection OS

Instead of the standard surface protection, the motors and gear units are available with

surface protection OS1 to OS4 as an option. The special procedure Z can also be per-

formed in addition. The special procedure Z means that large surface recesses are

sprayed with a rubber filling prior to painting.

Special

protective

measures

NOCO

®

fluid As standard, SEW-EURODRIVE supplies NOCO

®

fluid corrosion protection and

lubricant with every hollow shaft gear unit. Use NOCO

®

fluid when installing hollow shaft

gear units. Using this fluid helps prevent contact corrosion and makes it easier to

assemble the drive at a later date.

NOCO

®

fluid is also suitable for protecting machined metal surfaces that do not have

corrosion protection, including parts of shaft ends or flanges. You can also order larger

quantities of NOCO

®

fluid from SEW-EURODRIVE.

NOCO

®

fluid is food grade according to NSF certified H1.

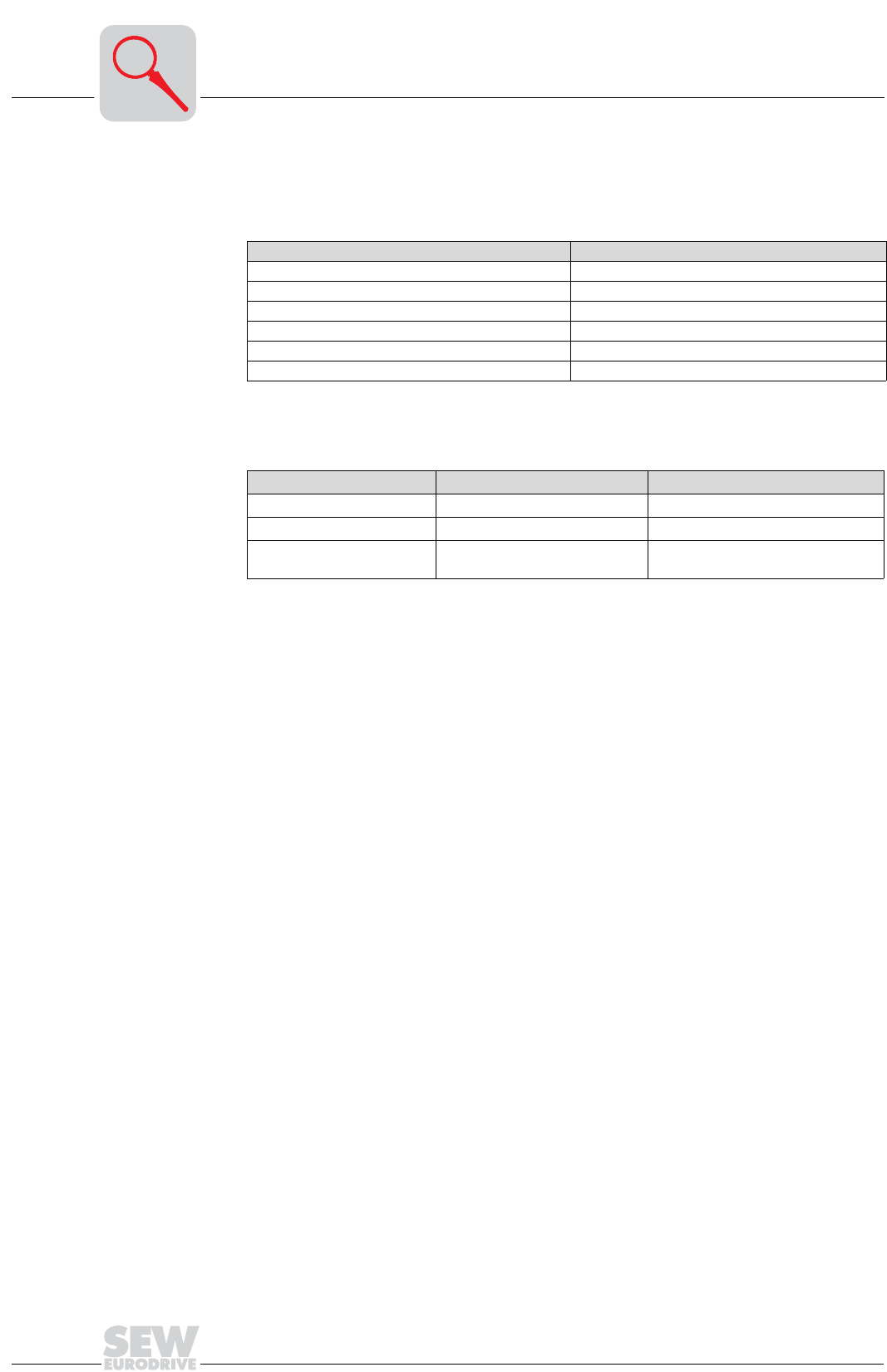

Surface protection Suitable for

OSG Primer only

Standard Normal ambient conditions

OS1 Low environmental impact

OS2 Medium environmental impact

OS3 High environmental impact

OS4 Very high environmental impact

Measure Protection principle Suitable for

FKM oil seal High quality material Drives subject to chemicals

PTFE oil seal High quality material Drives subject to chemicals

Stainless steel output shaft

Surface protection through high-

quality material

Particularly exacting applications in

terms of exterior surface protection