Technical data

Manual – Gear Units and Gearmotors

145

8

Selecting the inverter

Project Planning for AC Motors with Inverter

8.3 Selecting the inverter

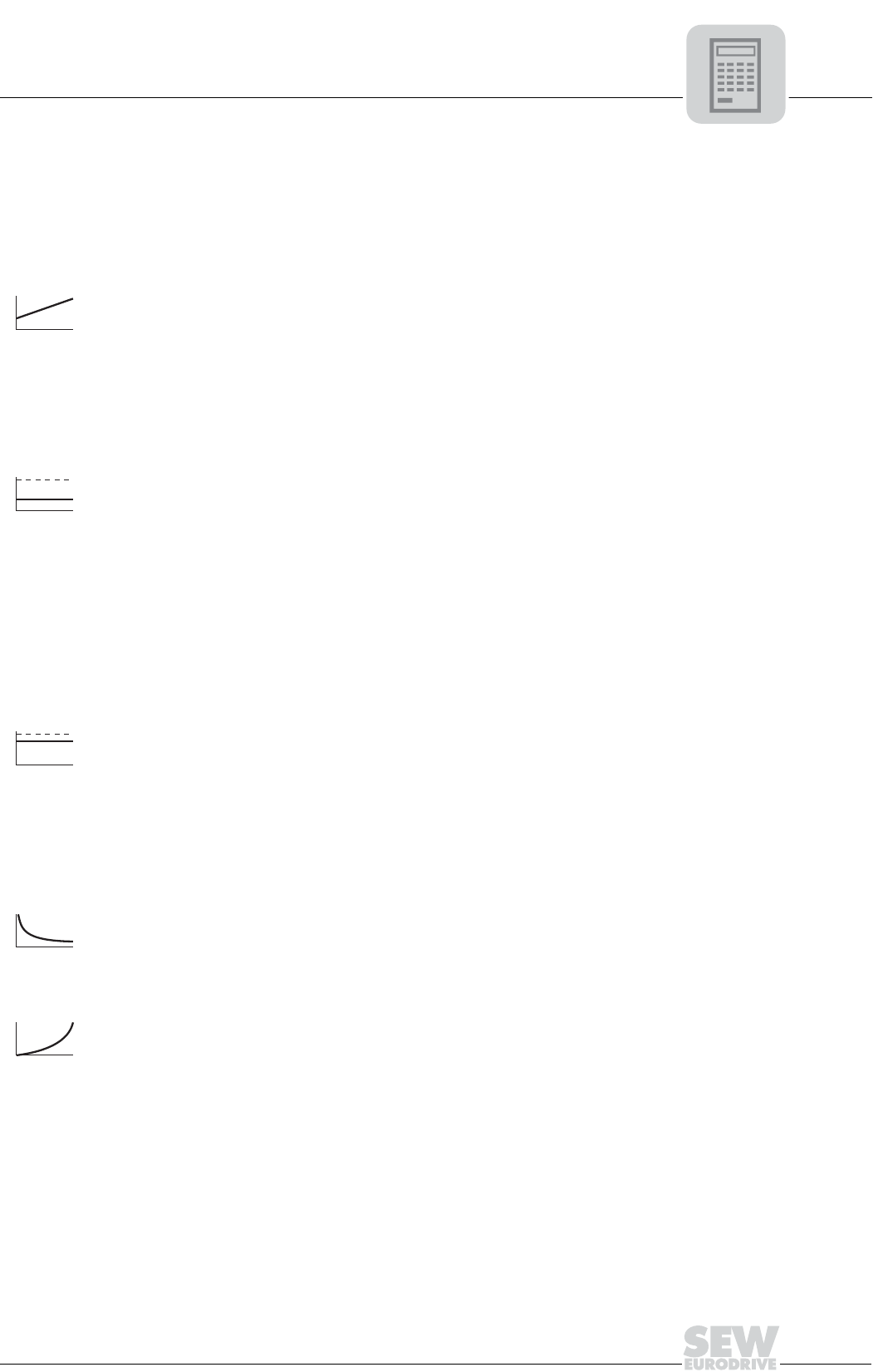

Drive categories The large number of different drive applications can be divided into five categories. The

five categories are listed below together with the recommended inverter. The assign-

ment is based on the required setting range and the resulting control process.

1. Drives with a base load and a speed dependent load, such as conveyor drives.

• Low requirements on the setting range.

–MOVITRAC

®

B

– MOVIDRIVE

®

MDX60/61B

• High requirements on the setting range (motor with encoder).

– MOVIDRIVE

®

MDX61B with DEH11B option

2. Dynamic load, e.g. trolleys; brief high torque demand for acceleration followed by low

load.

• Low requirements on the setting range.

–MOVITRAC

®

B

– MOVIDRIVE

®

MDX60/61B

• High requirements on the setting range (motor with encoder).

– MOVIDRIVE

®

MDX61B with DEH11B option

• High dynamic properties required (motor with encoder, preferably sin/cos encoder).

– MOVIDRIVE

®

MDX61B with DEH11B option

3. Static load, e.g. hoists; mainly steady high static load with overload peaks.

• Low requirements on the setting range.

–MOVITRAC

®

B

– MOVIDRIVE

®

MDX60/61B

• High requirements on the setting range (motor with encoder).

– MOVIDRIVE

®

MDX61B with DEH11B option

4. Load falling in inverse proportion to speed, e.g. winding or coil drives.

• Torque control (motor with encoder, preferably sin/cos encoder).

– MOVIDRIVE

®

MDX61B with DEH11B option

5. Variable torque load, e.g. fans and pumps.

• Low load at low speeds and no load peaks, 125% utilization (I

D

= 125% I

N

).

–MOVITRAC

®

B

– MOVIDRIVE

®

MDX60/61B