Owner's manual

Cleaning and service

25

• Repeat these steps two or three times to remove all air bubbles out of the

press. Then conduct a pressure test.

(See the following Chapter on the pressure test)

If you do not reach the required pressure of 25 tonnes during the pressure test,

there must be air in the press still. In that case, proceed as follows:

• Remove the die tool.

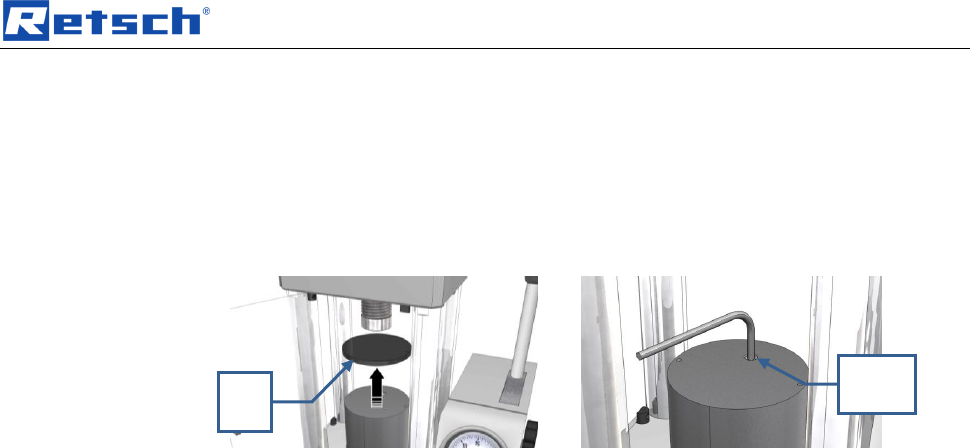

Fig. 16:

• Pull the cylinder plate (G) upwards and off.

• Use the supplied hex key to loosen the ventilation screw (ES).

• Close the shut-off valve (H).

• Using the lever (B), pump very slowly until oil appears in the ventilation

opening (ES).

It may be necessary to wait until no more air bubbles rise upwards.

• Then tighten the screw (ES) again and insert the pressing plate (G) again.

Pos: 8.18 /00005 Ü berschriften/ 1.1 Überschrifte n/1.1 Überschrift en BDA/11 Druc ktest @ 4\ mod_1322561088 719_9.doc @ 25835 @ 2 @ 1

5.8 Pressure Test

Pos: 8.19 /00010 Bedienungsa nleitungen Kapitels ammlungen/PP 25/0015 Be dienung/15xx PP 25 Modul Druc ktest @ 4\ mod_1322562738 796_9.doc @ 25925 @ @ 1

• Close the shut-off valve (H) by turning in a clockwise direction.

• Then pump by moving the hand levers forwards and backwards until a

pressure of at least 25 t is indicated in the pressure display.

Pos: 8.20 /00005 Ü berschriften/ 1.1 Überschrifte n/1.1 Überschrift en BDA/11 Üb erdrucksich erung @ 4\mo d_1322561084719 _9.doc @ 2580 8 @ @ 1

5.9 Overpressure relief

Pos: 8.21 /00010 Bedienungsa nleitungen Kapitels ammlungen/PP 25/0015 Be dienung/15xx PP 25 Modul Überdr ucksicherung @ 4\mod_ 1322562739468_9 .doc @ 25934 @ @ 1

There is an overpressure relief valve inside the press. This is set to 25-t. The

overpressure relief valve may be set only in the factory.

If the hand lever (B) is actuated when the set pressure of 25 t is actuated again,

the safety valve prevents damage to the press.

Pos: 9.1 /00005 Üb erschriften/1. Üb erschriften/1 Reinigung und Wartung @ 0\ mod_12311670 07723_9.doc @ 5450 @ @ 1

6 Cleaning and service

Pos: 9.2 /00005 Üb erschriften/1.1 Ü berschriften/ 1.1 Überschrift en BDA/11 R einigung @ 0\ mod_122690967 0239_9.doc @ 36 07 @ @ 1

6.1 Cleaning

Pos: 9.3 /00010 B edienungsanlei tungen Kapitelsa mmlungen/P P25/0040 Wartu ng, Reinigung und Verschleiß/ 4005 PP25 Mo dul Reinigung @ 4\mod_1322 729842800_9.d oc @ 25990 @ @ 1

Do not clean the press with running water. Use only a cloth dampened with water.

Do not use any solvents or aggressive cleaning agents!

Pos: 9.4 /00005 Üb erschriften/1.1 Ü berschriften/ 1.1 Überschrifte n BDA/11 W artung @ 0\ mod_122690969406 6_9.doc @ 36 13 @ @ 1

6.2 Service

Pos: 9.5 /00010 B edienungsanlei tungen Kapitelsa mmlungen/P P25/0040 Wartu ng, Reinigung und Verschleiß/ 4010 PP25 Mo dul Wartung @ 4\mod_13227 29879692_9.d oc @ 25998 @ @ 1

The press is for designed for many yearsof operation and requires only very little

servicing . From time to time, you should check if the threaded spindle on the press

can move easily.

• Clean and oil the press as required.

No further maintenance is needed.

Pos: 10.1 /00010 Bedienungsa nleitungen Kapitels ammlungen/------- Seitenum bruch ----------- @ 0\mod_122234437375 8_0.doc @ 238 6 @ @ 1

G

ES