Owner's manual

Operating the machine

21

• Build up some pressure force by moving the hand lever (B) forwards and

backwards until the pellet (PR) along with the pressure pieces fall out of the

die tool.

• Alternatively, you can press the pellet out of the die tool by turning

the threaded spindle (D).

• Open the shut-off valve (H) by turning in an anti-clockwise direction.

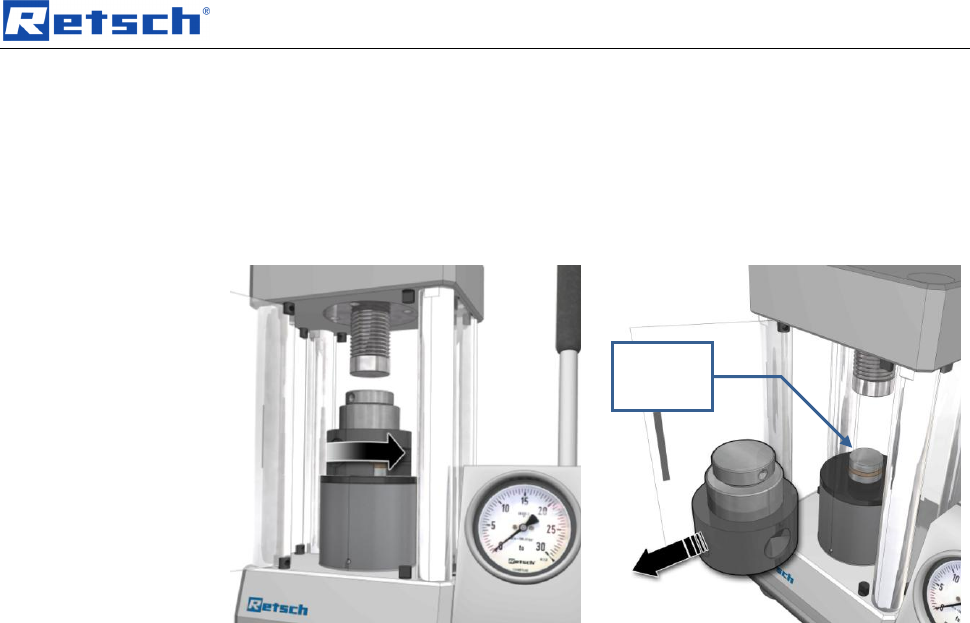

Fig. 7: Turning the die tool to allow removal

• Turn the die tool backwards by 180°.

• Remove the die tool.

• Then clean the die tool.

5.5.5 Instructions on Handling the Die Tool and the Pressing Plates

NOTE

Depending on the material and its composition, sample residue (e.g. salt residue)

clinging to the die tool can be very corrosive and cause irreparable damage to the

die tool. Please therefore clean the entire die tool thoroughly with water and then

with alcohol.

Store the die tool and its individual parts in as dry a place as possible until it is next

used.

Never scratch the pressing plates with a sharp object. You can remove hardened

sample residue with blotting or filter paper.

After cleaning them, keep the pressing plates in the accompanying boxes as

protection.

Pos: 8.14 /00005 Ü berschriften/ 1.1 Überschrifte n/1.1 Überschrift en BDA/11 Pr esswerkzeug – alternatives Ei nsetzten @ 4\ mod_1322561 087407_9.doc @ 25826 @ @ 1

5.6 Die Tool – Alternative Insertion

Pos: 8.15 /00010 Bedienungsa nleitungen Kapitels ammlungen/PP 25/0015 Be dienung/1525 P P25 Modul Press werkzeug - al ternatives Eins etzen @ 4\mo d_132256273 7561_9.doc @ 2 5907 @ 3 @ 1

In samples

• in which you cannot mix in any wax to stabilise the pellet or

• in unstable samples that are hard to compress

an alternative method of using the die tool is recommendable. This prevents pellets

falling when they are being ejected.

• Prepare the die tool and the sample as described in the previous chapter.

PR