Owner's manual

Operating the machine

17

Usually 20% wax is mixed in with the sample material. The mixing ratio here is 1

part wax and 4 parts sample material.

Essentially, this improves the durability and surface of the pellets for the

subsequent XRF analysis.

We recommend the Retsch MM400 for producing a homogeneous mixture of

sample material and the wax. Use a plastic beaker made of polystyrenefor mixing

(Art. no. 22.041.0003) and 4 grinding balls made of polyamide (Art. no.

05.368.0042).

The following parameters are recommended for the MM400 to ensure mixing

instead of grinding.

• Time = 2.00 min

• Frequency = 15 Hz

Pos: 8.10 /00005 Ü berschriften/ 1.1 Überschrifte n/1.1 Überschrift en BDA/11 Hin weise im Umga ng mit dem Pr esswerkzeug und den Pressplatt en @ 4\ mod_1323088267 953_9.doc @ 26067 @ 2 @ 1

5.4 Instructions on Handling the Die Tool and the Pressing Plates

Pos: 8.11 /00010 Bedienungsa nleitungen Kapitels ammlungen/PP 25/0015 Be dienung/1516 PP25 M odul Hin weise im Umga ng mit Presswer kzeug und Pre ssplatten @ 4\ mod_1322730 396454_9.doc @ 26006 @ @ 1

NOTE

Sample residue clinging to the die tool can be very corrosive depending on the

material and composition (e.g. salt residue) and cause irreparable damage to the

die tool. Please therefore clean the entire die tool thoroughly with water and then

with alcohol.

Store the die tool and its individual parts in as dry a place as possible until they are

used again.

Never scratch the pressing plates with a sharp object. You can remove hardened

sample residue with blotting paper or filter paper.

To protect the pressing plates, put them into the supplied boxes after cleaning.

Pos: 8.12 /00005 Ü berschriften/ 1.1 Überschrifte n/1.1 Überschrift en BDA/11 Pr esswerkzeug be dienen @ 4\m od_13225610 80954_9.doc @ 2 5790 @ @ 1

5.5 Operating the Die Tool

Pos: 8.13 /00010 Bedienungsa nleitungen Kapitels ammlungen/PP 25/0015 Be dienung/1520 PP25 M odul Press werkzeug bedie nen @ 4\m od_13225627 36999_9.doc @ 25 898 @ 3333 3 @ 1

5.5.1 Preparing the die tool

NOTE

Before using the die tool parts for the first time, please clean them with an organic

detergent in order to remove any oil residue.

• Remove every bit of dirt from the die tool.

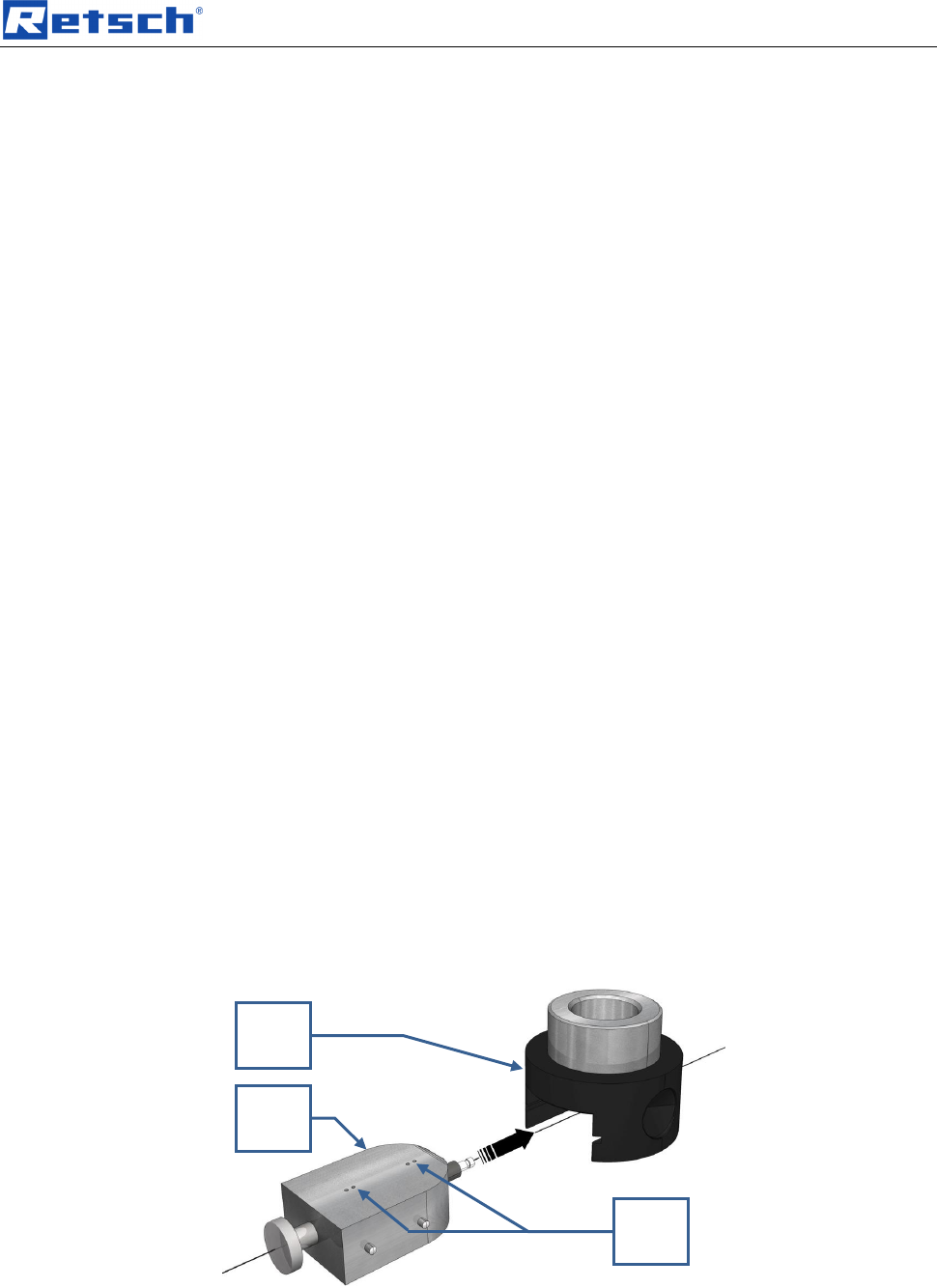

Fig. 4: Inserting the slide

• • Push the slide (S) into the basic body of the die tool (P). The

ventilation or evacuation boreholes (SB) should point upwards during this

procedure.

S

P

SB