Owner's manual

Operating the machine

16

Pos: 8.5 /00005 Üb erschriften/1.1 Ü berschriften/ 1.1 Überschrifte n BDA/11 Übersic htstabelle d er Geräteteile @ 0\ mod_122 8990616846_9. doc @ 4972 @ @ 1

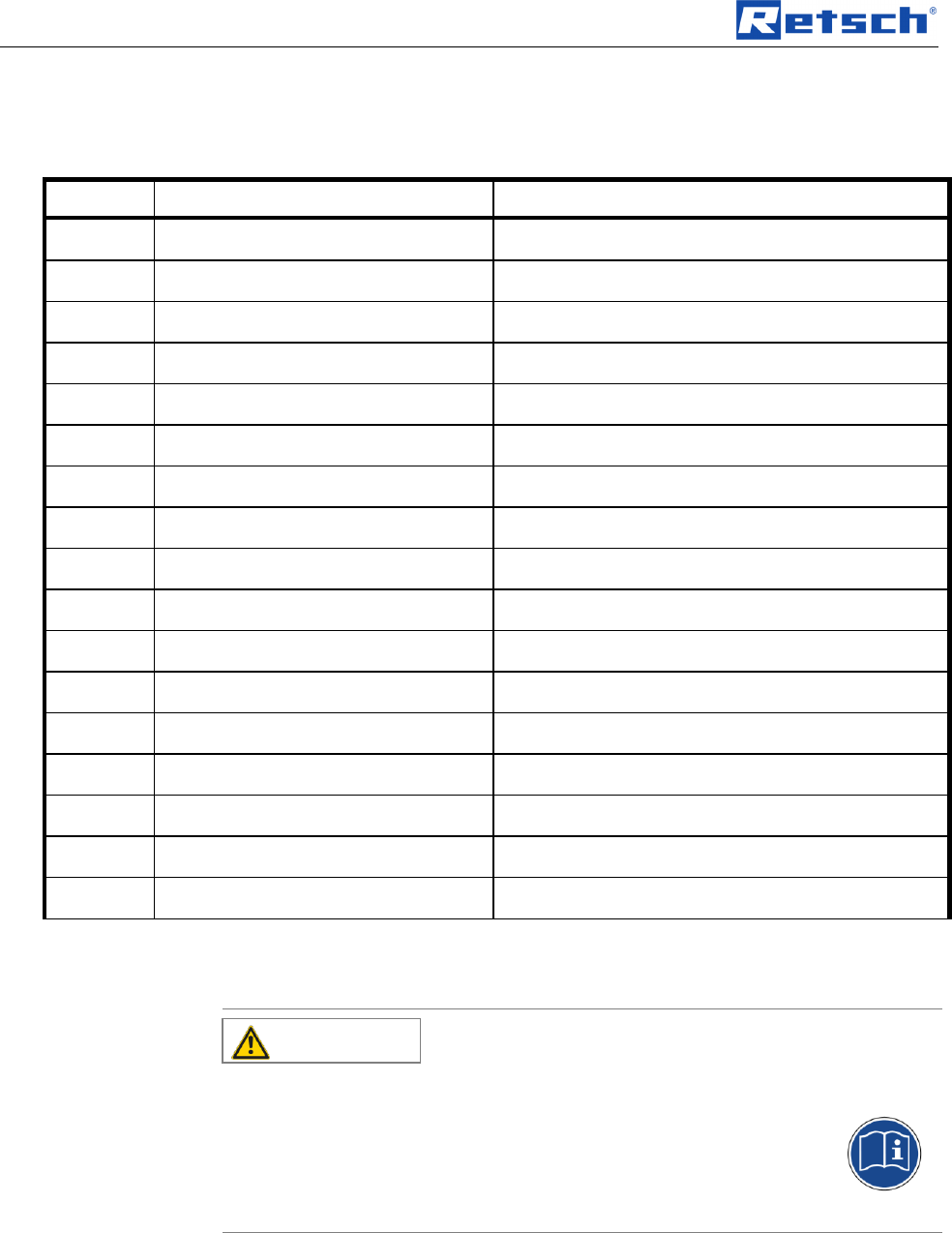

5.2 Overview table of the parts of the device

Pos: 8.6 /00010 B edienungsanlei tungen Kapitelsa mmlungen/P P25/0015 Bedien ung/1510 PP25 Modul Übersic htstabelle der Ger äteteile @ 4\ mod_132 2562735843_9.doc @ 25880 @ @ 1

Element

Description

Function

A

Handle hand wheel

Grip for turning the hand wheel (hinged)

B

Hand lever

Lever for operating the pump

C

Hand wheel

For turning the spindle into the pressing position

D

Threaded spindle

For tensioning the die tool

E

Pressing chamber door

Protective equipment

F

Centring ring

Positioning aid for die tool (alternative use)

G

Die plate

Cover on the pressing cylinder

H

Shut-off valve

Valve for building up pressure

J

Pressure cylinder

Presses the sample against the spindle

K

Pressure display

Indicates the level of pressure in the hydraulic system

L

Suction cups

Hold the press in position

M

Plunger

Builds up pressure

N/O

Pressure piece

Surrounds the sample

P

Basic body of the die tool

Accommodates the pressing parts

R

Vacuum connection

Adapter for evacuation

S

Slide

Anvil for pellets

PP

Pressing plate

Plate to aid pellet ejection

Pos: 8.7 /00005 Üb erschriften/1.1 Ü berschriften/ 1.1 Überschrifte n BDA/11 Pro benmaterial vorb ereiten @ 4\ mod_1322561 083376_9.doc @ 2 5799 @ @ 1

5.3 Preparing the Sample Material

Pos: 8.8 /00004 Warnhinweise/V 0006 VORSICHT Gefahr von P ersonenschä den Gefährliche Stoffe @ 1\ mod_1236238456 269_9.doc @ 7634 @ @ 1

CAUTION

Danger of personal injury

Dangerous nature of the sample

– Depending on the dangerous nature of your sample, take the

necessary measures to rule out any danger to persons.

• Observe the safety guidelines and datasheets of your

sample material.

Pos: 8.9 /00010 B edienungsanlei tungen Kapitelsa mmlungen/P P25/0015 Bedien ung/1515 PP25 M odul Probe nbmaterial vorb ereiten @ 4\ mod_13225627 36389_9.doc @ 25889 @ @ 1

These degrees of fineness can be achieved e.g. by grinding in a ball mill ,

preferably in the Retsch PM100; PM200; PM400; RS200 or MM400.

In most cases, particularly where hard materials are concerned, some wax powder

has to be mixed well with the ground sample before conducting the pressing

procedure.