User guide

Revision 1.2D Page 9 of 17

www.resourcedm.com

ML Switch User Guide

Warning

Please Note

The specifications of the product detailed on this

Set-Up Guide may change without notice. RDM

Ltd. shall not be liable for errors or for incidental

or consequential damages, directly and indirectly,

in connection with the furnishing, performance or

misuse of this product or document.

Ensure that all power is

switched off before

installing or maintaining

this product

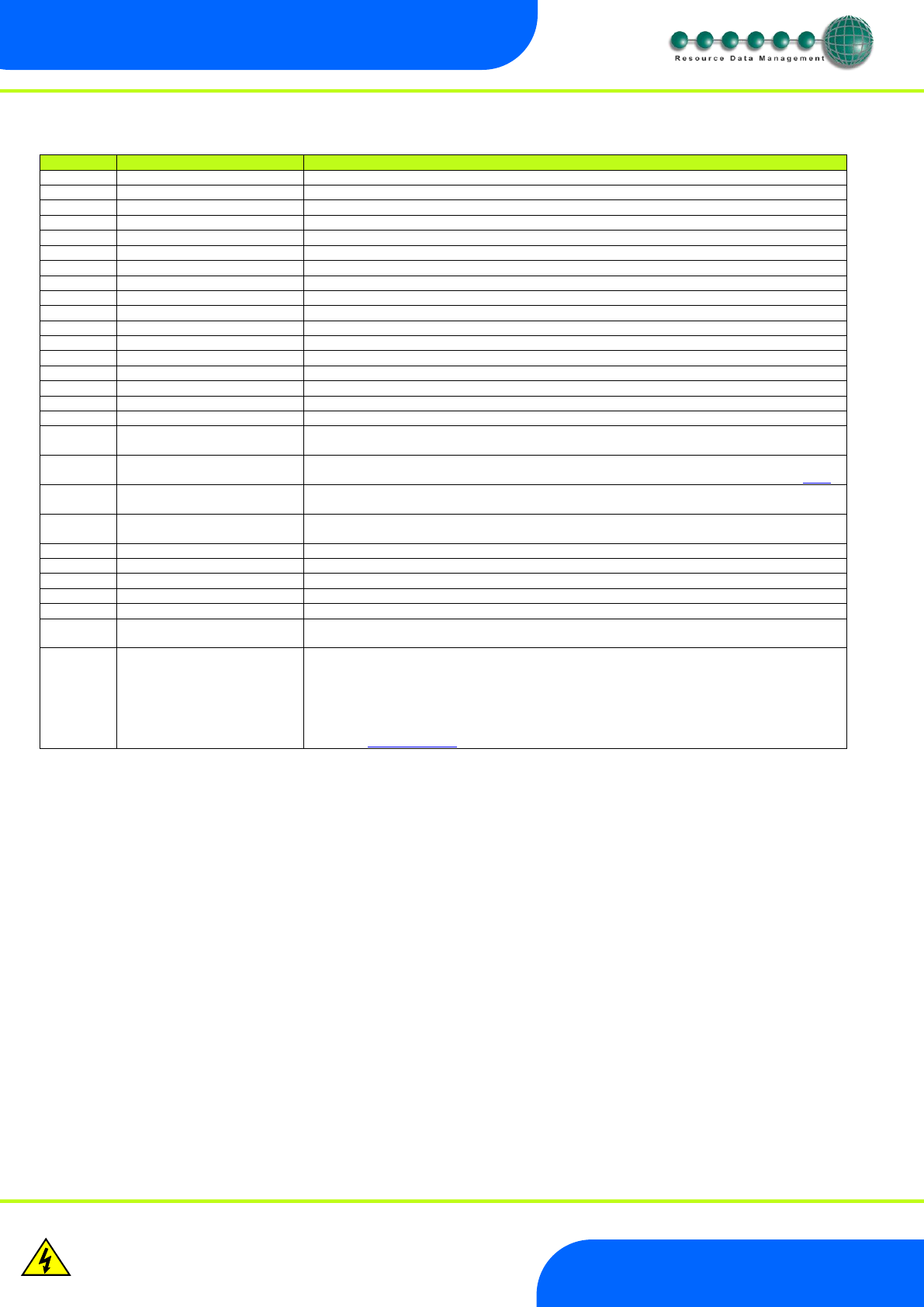

Parameters Description:

Number

Parameter

Description

P-01

Refrigerant

Select the gas type used within the refrigeration system.

P-02

Span

Total range of transducer*

P-03

Offset

Value below zero*

P-04

Glide

Glide characteristic (Offset to Evap Temperature)

P-05

Pressure Type

Select between Absolute or Gauge pressure

P-11

Evap 1 offset

Pressure difference between suction transducer and evaporator 1

P-12

Evap 2 offset

Pressure difference between suction transducer and evaporator 2

P-13

Evap 3 offset

Pressure difference between suction transducer and evaporator 3

P-14

Evap 4 offset

Pressure difference between suction transducer and evaporator 4

P-15

Evap 5 offset

Pressure difference between suction transducer and evaporator 5

P-16

Evap 6 offset

Pressure difference between suction transducer and evaporator 6

P-17

Evap 7 offset

Pressure difference between suction transducer and evaporator 7

P-18

Evap 8 offset

Pressure difference between suction transducer and evaporator 8

P-19

Evap 9 offset

Pressure difference between suction transducer and evaporator 9

P-20

Evap 10 offset

Pressure difference between suction transducer and evaporator 10

P-31

Transducer Fault Delay

Alarm generated, once transducer fault delay expires, if the transducer fails.

P-32

Alarm Delay

Delay before the HP alarm is generated.

P-33

HP Alarm

If the pressure exceeds this value then a High Pressure alarm is generated once the alarm

delay expires.

P-40

MOP

If the pressure exceeds this value the valves on controllers connected to the ML Switch will

closed or be reduced to a predetermined percentage. A MOP alarm is also created. (See MOP)

P-41

MOP Diff

When the pressure reduces below this value valves on controllers connected to the Switch will

recover to their normal operational

P-42

Recovery Count

When the Switch comes out of MOP, the valves will come on at 1 minute intervals and turn

“this” number of valves on per minute.

P-43

MOP Delay

Delay after the MOP value has been exceeded before the MOP actions and alarm occurs.

P-50

Humidity Low

Sets humidity low level.

P-51

Humidity High

Sets humidity high level.

P-52

Trim Low

Sets trim low level.

P-53

Trim High

Sets trim high level.

P-54

Trim Off Level

When the timer is in the off period the trims will be pulsed at this value. Note if the humidity

sensor fails the trim relays will be pulsed at this level.

P-55

Trim Mode

Off – Pulses the controller trim relays at the Trim Off Level.

On - trim control feature will continuously pulse the controller trim relays dependant

on the measured humidity.

Re mote – Uses Data Manager GP Timer channel to determine when to control. See

GP Timer Setup

* Span and Offset allows for the full range of the transducer to be used by the ML Switch.

Span is the full range of the transducer

Offset is the value below zero.

E.g. Danfoss AKS 33 with range: -1 bar to 12 bar

Span would be 190 (13 bar)

Offset would be -15 (-1 bar)