Technical data

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

PREACTION SPRINKLER

SYSTEM

Page 8

February, 2010

II. SYSTEM TYPES AND

APPLICATIONS

Preaction systems are used in areas where

a common wet pipe or dry pipe sprinkler

system would present a greater potential

of facility damage in the unlikely event of

unintentional water discharge. Examples of

this include:

Computer rooms

Telecommunications facilities

Museums

Libraries

Coolers and freezers

A. Single-Interlocked Preaction

System (Figures 8a-10c)

This type of system is used where it

is desirable to have water available

at the sprinkler when the sprinkler

fuses. Viking single interlock systems

may have a pneumatic, hydraulic, or

electric detection system:

1. Pneumatic Release

A pneumatically actuated system uses a pneumatic actuator subjected to a minimum 30 PSI

(2 bar) air pressure for system water pressures of 175 PSI (12 bar) or less. For system water

pressures above 175 PSI, up to a maximum of 250 PSI (17 bar), 50 PSI (3.4 bar) air pressure is

required for the pneumatic actuator.

When Using a Model E or F Series Deluge Valve: The pneumatic actuator is installed in the

1/2” release line above the pressure operated relief valve (PORV) and the emergency release.

This is done to establish water pressure in the deluge valve prime chamber from air pressure in

the detection system. Refer to Figures 8a and 8b.

In fire conditions, when a heat activated releasing device opens to cause a loss of air pressure in

the release line, the pneumatic actuator opens to vent the pressure in the deluge valve priming

chamber and release the water faster than it can be replaced through the restricted priming line

connection, opening the deluge valve (see Figure 8c).

2. Hydraulic Release

This requires a hydraulic release system equipped with thermostatic (rate-of-rise) releases, and/or

fixed-temperature releases, and/or pilot heads. The system piping remains empty until the deluge valve

is activated by operation of the release system. When a releasing device operates, pressure in the

priming chamber of the deluge valve is relieved faster than it can be replenished through the restricted

orifice. Supply pressure overcomes the deluge valve clapper differential, forcing the clapper off its seat,

allowing water to flow to the system outlets and sound the water flow alarm. (Refer to Figures 9a-9b).

3. Electric Release

Electrically controlled preaction systems require an eletric solenoid valve controlled by an ap-

proved release control panel with compatible detection system. In the SET condition, water supply

pressure is trapped in the priming chamber by check valve and normally closed solenoid valve.

Refer to Figures 10a and 10b. In fire conditions, when the detection system operates, the system

control panel energizes solenoid valve open. Pressure is released from the priming chamber

faster than it is supplied through restricted orifice and the deluge valve opens (Figure 10c).

•

•

•

•

•

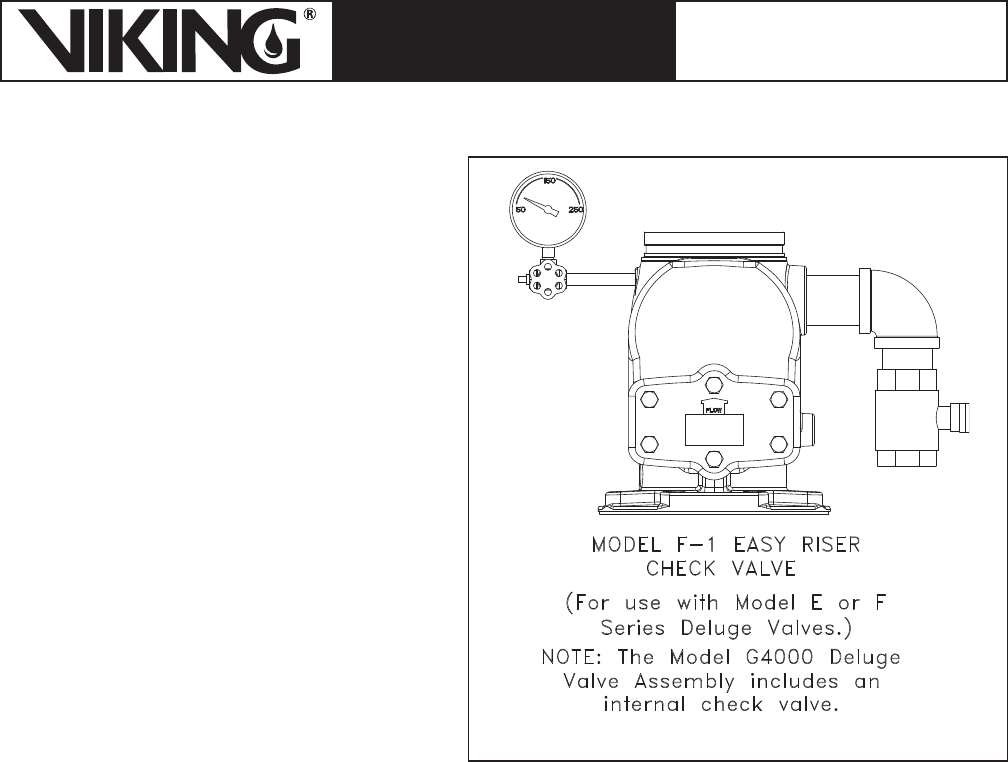

Figure 7