Technical data

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

PREACTION SPRINKLER

SYSTEM

Page 50

February, 2010

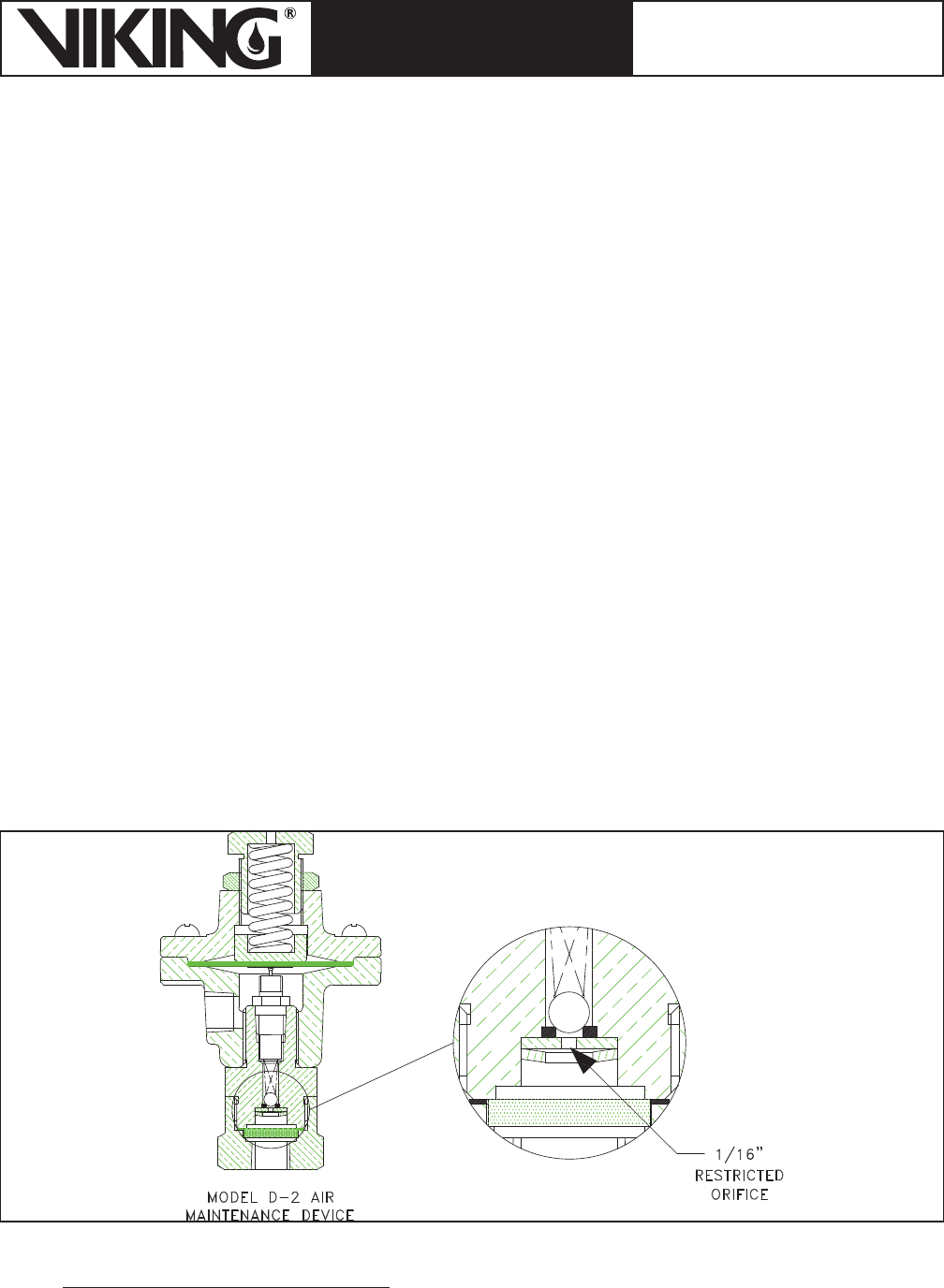

Figure 31

Pressure to be Maintained in a Pneumatic Release System: For recommended pneumatic (air or nitrogen)

pressures to be maintained in pneumatic release systems, refer to current Viking technical data for the system

used. For additional information concerning pneumatic release system equipment, devices, and installation

instructions, refer to the Viking Engineering and Design Data book section describing Pneumatic Supplies.

Release Line Restriction: All pneumatic-release systems must be equipped with a restricted orifice in the

air or nitrogen supply to ensure that the automatic air supply cannot replace pneumatic pressure as fast

as it escapes when a releasing device operates.

This restriction is already incorporated in the Viking air maintenance device and release line air supply

assembly. The air maintenance device contains a 1/16 inch (.16 mm) orifice (Figure 31), which restricts

the flow of air into the system so that when a sprinkler opens, air pressure will not enter the system faster

than it will discharge through a sprinkler. The bypass valve is kept closed and opened only to speed up the

filling of the system piping to the required pressure in the required time.

Reducing Trip Time: If the system trip time is excessive, it can be substantially reduced by one or more of

the following:

1. Add a check valve (Circle Seal or equivalent) in branch portions of the release-line system. (Install

so flow is toward releasing device).

2. Install an optional accelerator on the pneumatic release system to provide earlier alarms and/or allow the

system to trip faster. An accelerator may be necessary to meet system discharge time requirements.

Release Line Dehydrator: Due to problems that accumulated condensation can cause, especially on

freezer systems, all pneumatic release systems must be provided with a properly sized and maintained air

dehydrator installed on the air supply (Figure 32). It is important that the color of the desiccant be checked

at regular intervals to ensure its drying capability.

Pneumatic Supply: Refer to Viking technical data, system data, and associated schematic drawings for

the preaction system used. Also, refer to the Viking Engineering and Design Data book section describing

“Pneumatic Supplies” for additional information on pneumatic (air or nitrogen) equipment, devices, and

installation requirements.

Electric Release System Requirements

Viking preaction systems can be activated electrically through the use of a solenoid valve (Figures 32 and

33). The solenoid reacts to device actuation by opening, relieving pressure from the priming chamber of

the deluge valve (Figure 34). Note the electrical characteristics of the solenoid valve, as it must be compat-

ible with the system control panel and other electrical components. Observe all manufacturer’s technical

instructions.