Technical data

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

Telephone: 269-945-9501 Technical Services 877-384-5464 Fax: 269-818-1680 Email: techsvcs@vikingcorp.com

PREACTION SPRINKLER

SYSTEM

Page 42

February, 2010

Set release system air pressure supervisory switch to activate at 25 PSI (1.7 bar) on pressure drop

for system water pressures of 175 PSI (12 bar) or less. For system water pressures above 175 PSI,

up to a maximum of 250 PSI (17 bar), set the air pressure supervisory switch to activate at 45 PSI

(2.4 bar) on pressure drop. Air pressure supervisory switch should be wired to activate an alarm to

signal a low air pressure condition. Activation of an alarm to signal a high pressure condition may be

required. Refer to applicable installation standards and the Authority Having Jurisdiction.

2A. For Viking double interlock preaction systems with electric/pneu-lectric release using a Model E

or F series deluge valve: Refer to the settings in Table 2. Recommended pneumatic supervisory

pressure in the closed sprinkler piping is 30 PSI (2.1 bar). The air supervisory switch should be

equipped with two sets of independently adjustable contacts. On systems with a Model E or F

series deluge valve, use the Viking Pressure Supervisory Switch as air supervisory switch.

For 30 PSI (2.1 bar) supervisory pressure:

Adjust one set of contacts of air supervisory switch to activate at 25 PSI (1.7 bar) on pressure drop.

These contacts should be wired to activate a “Low-Air” supervisory alarm.

The other set of contacts in the air supervisory switch should activate at 20 PSI (1.4 bar) on pres-

sure drop. Wire these contacts to activate the remaining initiating circuit of the system control panel

configured for “cross-zoned” operation. For the VFR400 Release Control Panel, refer to the appropriate

wiring diagram packed with the panel. Activation of an alarm to signal a high-pressure condition may

be required. Refer to applicable installation standards and the Authority Having Jurisdiction.

Installation Standards may allow supervisory pressures lower than those recommended above.

For pneumatic supervisory pressure of 10 PSI (.7 bar), use Viking Alarm Pressure Switch as air

supervisory switch.

For 10 PSI (.7 bar) Supervisory Pressure:

Adjust one set of contacts of air supervisory switch to activate at 7.5 PSI (.52 bar) on pressure

drop. These contacts should be wired to activate a “Low-Air” supervisory alarm.

The other set of contacts in air supervisory switch should activate at 5 PSI (3.4 bar) on pressure drop.

Wire these contacts to activate the remaining initiating circuit of the system control panel configured

for “cross-zoned” operation. For the VFR400 Release Control Panel, refer to the appropriate wiring

diagram packed with the panel. Activation of an alarm to signal a high-pressure condition may be

required. Refer to applicable installation standards and the Authority Having Jurisdiction.

Note: When using supervisory pressures, settings, or equipment other than those recommended

above, verify that air regulation equipment and air supervisory switches used are compatible with

the supervisory pressure setting used.

Supervisory pressures other than the recommended settings noted above may affect operation of

the system.

Release Devices

The release system shall serve all areas that the preaction system protects to ensure that in the event of

a fire, the release system will activate and provide water to the system and the affected area. There are

a number of release system devices that can be used in the detection system. The simplest of these is to

use sprinklers in a pilot line under system water pressure. The pilot line is piped to the area protected with

connections to the emergency release.

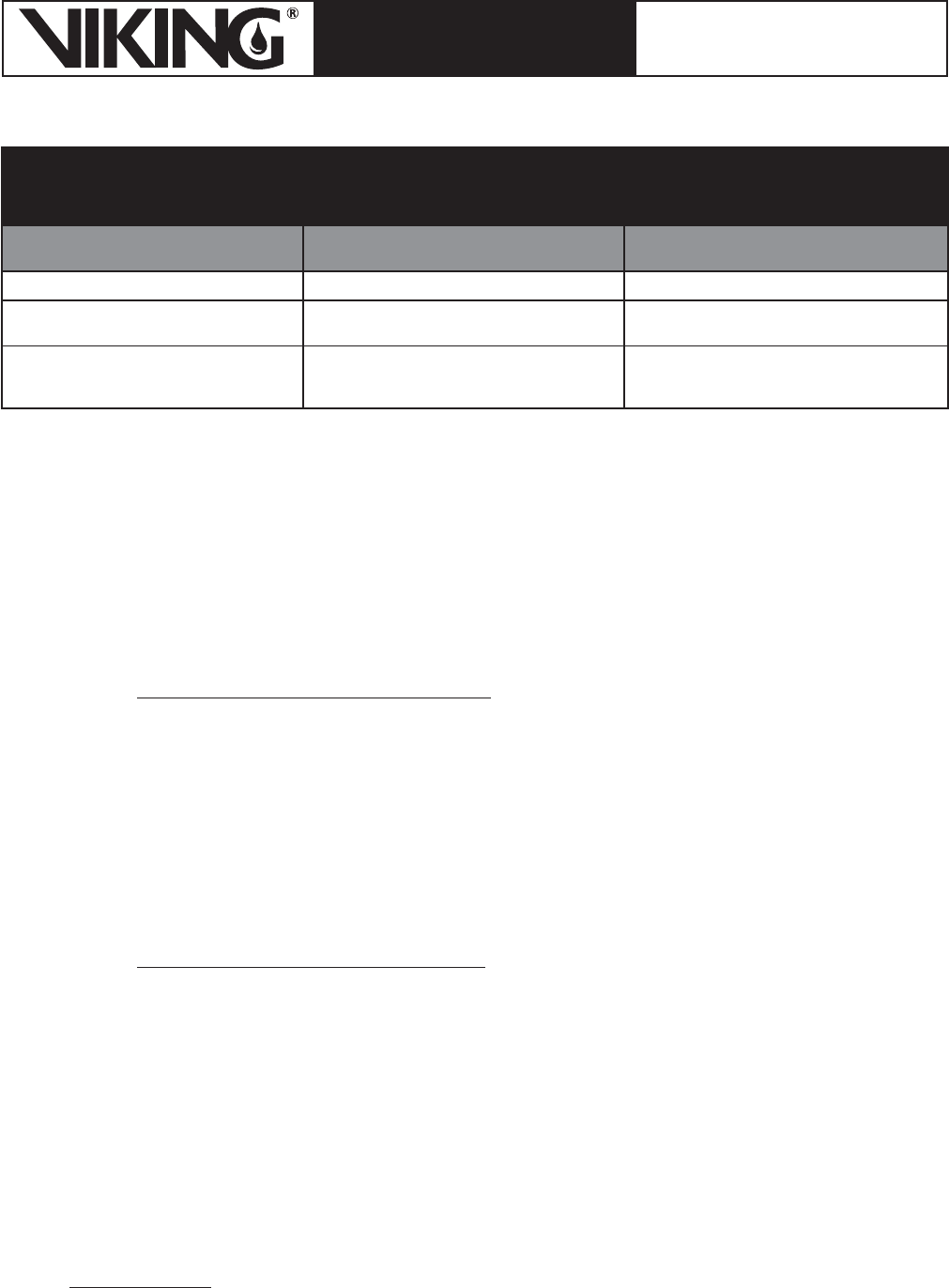

TABLE 2: RECOMMENDED PNEUMATIC SUPERVISORY PRESSURES AND SETTINGS

FOR VIKING DOUBLE INTERLOCK PREACTION SYSTEMS WITH ELECTRIC/PNEU-LECTRIC RELEASE

(FOR SYSTEMS USING A MODEL E OR F SERIES DELUGE VALVE)

Device

For Supervisory Pressure of 30 PSI (2.1 bar)

Set to Maintain

For Supervisory Pressure of 10 PSI (.7 bar)

Set to Maintain

Air Maintenance Device 30 PSI (2.1 bar) 10 PSI (.7 bar)

Low-Air Alarm Contact Setting on Release

System Pressure Supervisory Switch

25 PSI (1.7 bar) On Pressure Drop 7.5 PSI (.52 bar) On Pressure Drop

Setting for Contacts on Release System

Pressure Supervisory Switch to activate

Release Control Panel Initiating Circuit

20 PSI (1.4 bar) on Pressure Drop 5 PSI (.34 bar) on Pressure Drop