User Manual

32

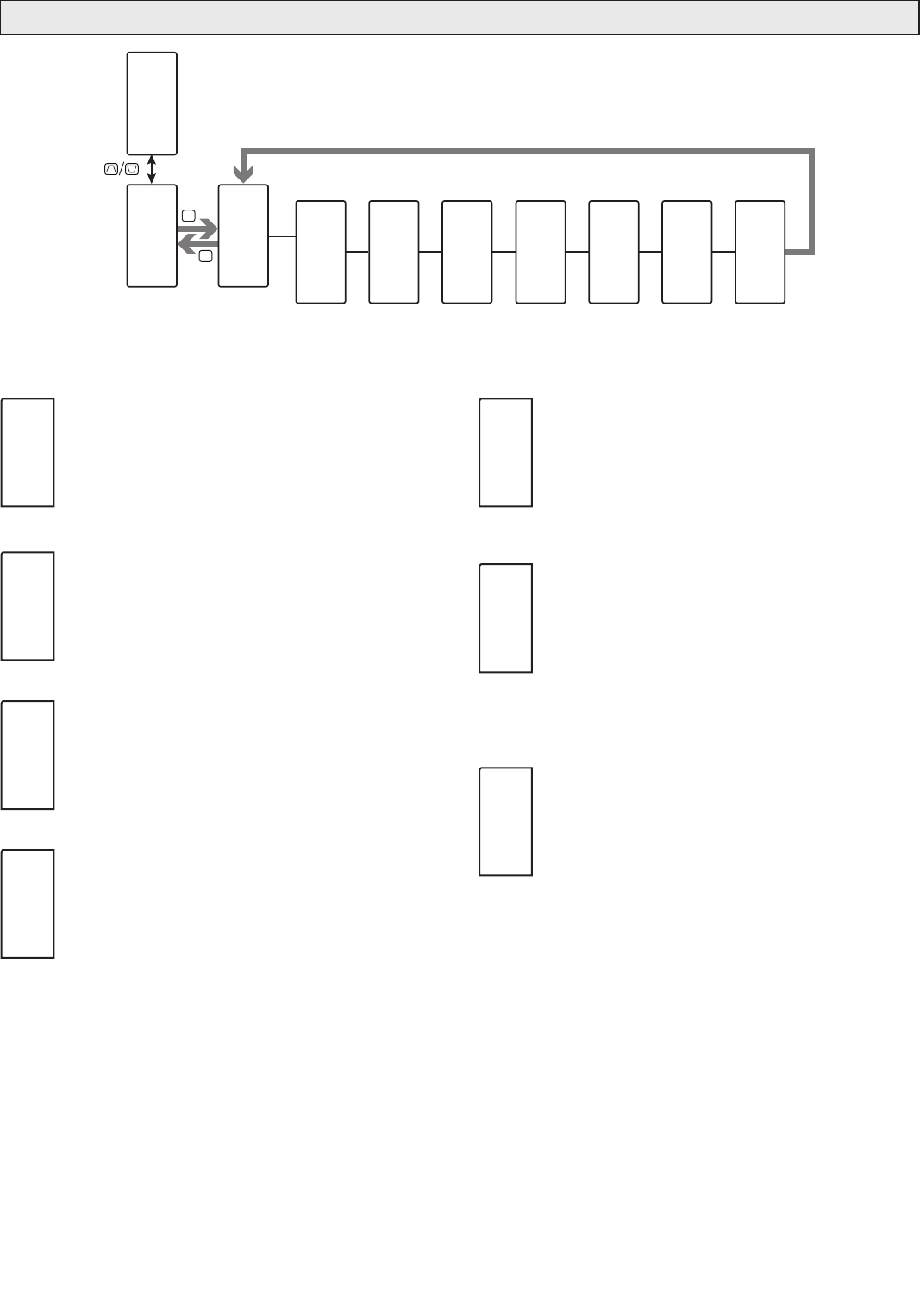

Setpoint

Selection

Setpoint 1

Value

Setpoint 2

Value

F1

F2

P

D

Pro

NO

Pro

Pid

Pid

SP

SPSL

SP1

SP1

0.0

°F

SP2

0.0

°F

Setpoint

Low Limit

SPLO

0.0

°F

Setpoint

High Limit

SPHI

999.9

°F

Setpoint

Ramping

Timebase

SPrP

OFF

Setpoint

Ramp Rate

SPrr

0.0

°F

pid parameTers: seTpOinT parameTers (SP)

SETPOINT SELECTION

SP1 SP2

Select the desired Setpoint Value (SP1 or SP2) to use as the control

point. The SP Select function can also be configured in the Display

Parameter LOCS Menu (Pid LOCS) or a User Input or Function Key can

be assigned to the Setpoint Select Function.

SETPOINT 1 VALUE

-1999 to 9999

One of the two values that may be selected as the target setpoint

of the process.

SETPOINT 2 VALUE

-1999 to 9999

One of the two values that may be selected as the target setpoint

of the process.

SETPOINT LOW LIMIT

-1999 to 9999

Select the desired Setpoint Low Limit value. This value should be

selected so that the controller setpoint value cannot be set outside the

safe operating range of the process.

SETPOINT HIGH LIMIT

-1999 to 9999

Select the desired Setpoint High Limit value. This value should be

selected so that the controller setpoint value cannot be set outside the

safe operating range of the process.

SETPOINT RAMPING TIMEBASE

OFF SEC MIN hour

Select the desired unit of time for ramping of the process:

OFF

= Off

SEC

= Seconds

MIN

= Minutes

hour

= Hours

SETPOINT RAMP RATE

0 to 9999

The Ramp Rate property is used to reduce sudden shock to a

process during setpoint changes and system startup, a setpoint ramp

rate can be used to increase or decrease the Target Setpoint at a

controlled rate. The value is entered in units/time. A value of 0

disables setpoint ramping. If the Setpoint Ramp Rate is a non-zero

value, and the Actual Setpoint is changed or the controller is powered up, the

controller sets the Target Setpoint to the current process measurement, and uses

that value as its setpoint. It then adjusts the Target Setpoint according to the

setpoint Ramp Rate. When the Target Setpoint reaches the Actual Setpoint, the

controller resumes use of the Actual Setpoint value. (In a properly designed and

functioning system, the process will have followed the Target Setpoint value to

the Actual Setpoint value.)

SPSL

SP1

SP1

0.0

°F

SP2

0.0

°F

SPLO

0.0

°F

SPHI

999.9

°F

SPrP

OFF

SPrr

0.0

°F