Product Manual

31

SECTION 15

MAINTENANCE INSTRUCTIONS

Read and follow all the maintenance instructions provided

in this manual to keep the machine in good operating

condition. Regular inspections and proper maintenance

are essential to preventing accidents and injuries. These

instructions will help you service the unit. Instructions are

for a person with some mechanical ability and training. No

attempt has been made to describe all basic steps such

as how to loosen or tighten fasteners. Basic procedures

such as cycling systems and checking operation of the

equipment are not fully described since they have been

described previously in this manual. Do not attempt to

perform work beyond your ability or at which you have no

experience. If you need assistance, call an authorized ser-

vice center or contact the factory.

DAILY

tCheck the tire pressure gauge function, and check the

accuracy monthly. Use a pressurized tire and a high quality

pressure gauge. If the gauge is defective, replace it imme-

diately.

tMake sure all fasteners are securely tightened and all

guards and covers are in place.

tCheck for worn, damaged or missing parts including

grips and protective covers. Replace them before allowing

the unit to be used.

tCheck oil level and remove water from the separator.

tInspect the unit and check to be certain that all systems

are operating normally. Follow detailed inspection and

testing procedures as specified for various components at

regular intervals.

MONTHLY

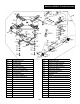

t Pivot Points, assist tower vertical shaft should be

cleaned with a vaporizing solvent and then lubricated with

chassis grease. (See Fig 15.1)

tCheck adjustment of the mount/demount head.

tCheck the condition and adjustment of the turntable

drive belt.

tCheck function of the Inflation Pedal pressure

limiter/ regulator. The pressure regulator should never

be adjusted to exceed 60 PSI.

tClean the table top, clamps, steel mount/demount

head, and other working surfaces with a vaporizing solvent.

tReplace any damaged or missing safety decals, avail-

able from the factory.

Mount/Demount Tool Head Adjustment

To adjust tool head clearance, adjust locking nut up or

down until lift clearance is 1/8” to 3/16”. Recheck clearance.

(See Fig 15.2)

Mount/Demount Head Cleaning

Clean dirt and debris from the mount/demount tool roller

with small screw driver or pick. Lubricate with light

penetrating oil. (See Fig. 15.3)

Fig 15.2

Adjusting

Nut

Locking

Nut

Fig 15.1

Lubricate

Here

Lubricate

Here

Fig 15.3