Installation Guide

6

III. Water Piping and Trim

WARNING

Failure to properly pipe boiler may result in

improper operation and damage to boiler or

building.

A. Design and install boiler and system piping to

prevent oxygen contamination of boiler water.

Oxygen contamination sources are system leaks

requiring addition of makeup water, ttings, and

oxygen permeable materials in distribution system.

Eliminate oxygen contamination by repairing system

leaks, repairing ttings, and using non-permeable

materials in distribution system.

B. Install circulator with anges, gaskets and bolts

provided.

C. Install Safety Relief Valve. Safety Relief Valve must

be installed with spindle in vertical position.

WARNING

Safety relief valve discharge piping must be piped

near oor to eliminate potential of severe burns.

Do not pipe in any area where freezing could

occur. Do not install any shut-off valves.

D. Connect system supply and return piping to boiler.

Refer to Figures 4 and 5. Also consult Residential

Hydronic Heating Installation and Design I=B=R

Guide. Maintain minimum ½ inch clearance from hot

water piping to combustible materials.

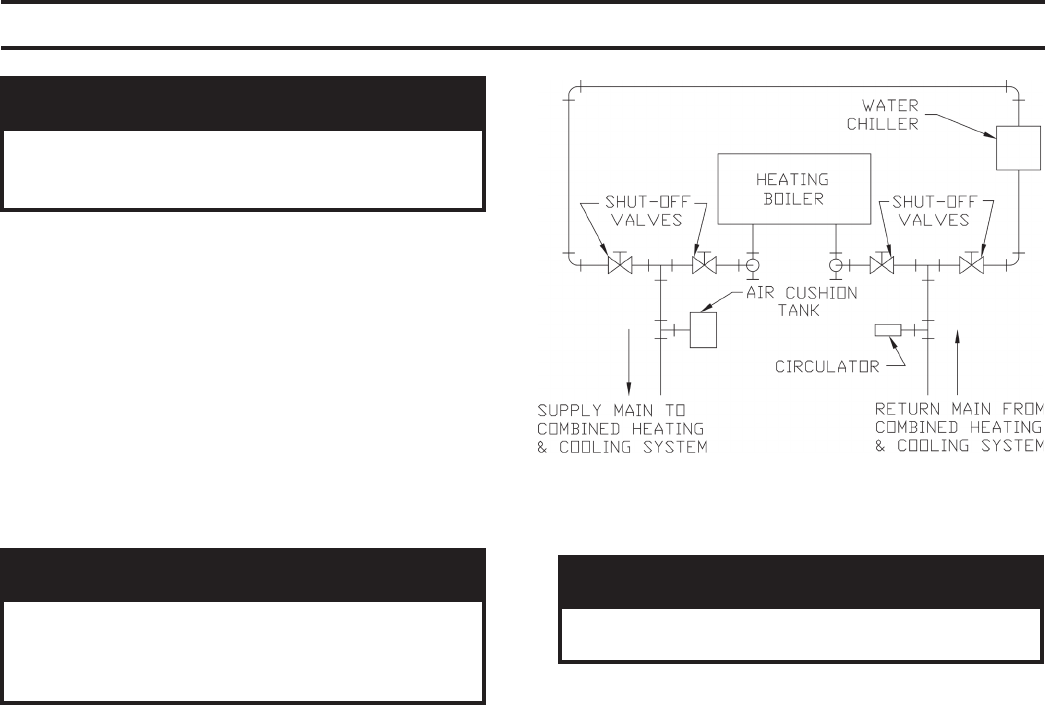

E. If boiler is used in connection with refrigeration

systems, boiler must be installed with chilled medium

piped in parallel with the heating boiler using

appropriate valves to prevent chilled medium from

entering boiler. See Figure 3. Also consult Residential

Hydronic Heating Installation and Design I=B=R

Guide.

F. If boiler is connected to heating coils located in

air handling units where they may be exposed to

refrigerated air, boiler piping must be equipped with

ow control valves or other automatic means to prevent

gravity circulation of boiler water during operation of

cooling system.

G. Use a boiler bypass if the boiler is to be operated

in a system which has a large volume or excessive

radiation where low boiler water temperatures may be

encountered (i.e. converted gravity circulation system,

etc.).

CAUTION

Boiler return water cannot be lower than 130°F for

proper function.

Install bypass between boiler supply and return in near

boiler piping as shown in Figures 4 and 5. Bypass

should be same size as the supply and return lines with

valves located in bypass and supply outlet as illustrated

in Figures 4 and 5 in order to regulate water ow to

maintain higher boiler water temperatures.

Set by-pass and boiler supply valves to half throttle

position to start. Operate boiler until system water

temperature reaches normal operating range.

Adjust valves to provide 180° to 200°F supply water

temperature. Opening the boiler supply valve will raise

system temperature, while opening by-pass valve will

lower system supply temperature.

H. If it is required to perform a long term pressure

test of the hydronic system, the boiler should rst be

isolated to avoid a pressure loss due to the escape of air

trapped in the boiler.

To perform a long term pressure test including the

boiler, ALL trapped air must rst be removed from the

boiler.

A loss of pressure during such a test, with no visible

water leakage, is an indication that the boiler contained

trapped air.

Figure 3: Recommended Piping for Combination

Heating & Cooling (Refrigeration) Systems