User manual

Table Of Contents

- 1. INTENDED USE

- 2. PRECAUTIONARY MEASURES

- 3. WARRANTY CONDITIONS

- 4. UNPACKING AND MOUNTING

- 5. CONSTRUCTION

- 6. GETTING STARTED

- 7. KEYPAD OVERLAY

- 8. FUNCTIONS OF KEYS

- 9. PROGRAM STRUCTURE

- 10. INDICATING WINDOW

- 11. LOGGING ON

- 12. NAVIGATING WITHIN THE MENU

- 13. WEIGHING

- 14. SCALE PARAMETERS

- 15. COMMUNICATION

- 16. DEVICES

- 17. DISPLAY

- 18. INPUTS / OUTPUTS

- 19. AUTHORIZATION

- 20. OTHER PARAMETERS

- 21. CUSTOMER CALIBRATION

- 22. SPECIAL FUNCTIONS OF WORKING MODES

- 23. WORK MODE - WEIGHING

- 24. WORKING MODES – COUNTING PIECES

- 25. WORKING MODES – DEVIATIONS

- 26. WORKING MODES – COMPARATOR

- 27. DATABASES

- 28. COMMUNICATION PROTOCOL

- 28.1. General information

- 28.2. Inventory of RS commands

- 28.3. Respond message format

- 28.4. Command’s description

- 28.4.1. Zeroing

- 28.4.2. Tarring

- 28.4.3. Get tare value

- 28.4.4. Set tare value

- 28.4.5. Send the stable result in basic unit

- 28.4.6. Send the result immediately in basic unit

- 28.4.7. Send the stable result in current unit

- 28.4.8. Send the result immediately in current unit

- 28.4.9. Switch on continuous transmission in basic unit

- 28.4.10. Switch off continuous transmission in basic unit

- 28.4.11. Switch on continuous transmission in current unit

- 28.4.12. Switch off continuous transmission in current unit

- 28.4.13. Set lower threshold

- 28.4.14. Set upper threshold

- 28.4.15. Read lower threshold

- 28.4.16. Read upper threshold

- 28.4.17. Send all implemented commands

- 28.5. Manual printouts / automatic printouts

- 29. CONNECTING EXTERNAL DEVICES

- 30. DIAGRAMS OF CONNECTION CABLES

- 31. TECHNICAL PARAMETERS

- 32. ERROR MESSAGES

- 33. ADDITIONAL EQUIPMENT

- 34. APPENDIX A – Variables for printouts

- 35. APPENDIX B – Functions of programmable buttons

- 36. APPENDIX C – Label pattern

- 37. APPENDIX D - CITIZEN printer setting

- 38. APPENDIX E - ZEBRA printer setting

- 39. APPENDIX F - Communication with barcode scanners

118

39. APPENDIX F - Communication with barcode scanners

1. For communication with barcode scanners RADWAG scales use RS232

interfaces and simplex transmission (one direction) without handshaking.

Only two wires are required for assuring such a transmission. Used

scanners should be equipped in such interface with disabled both

hardware and software handshaking.

2. Both scales and scanners have the possibility of setting of transmission

parameters. Both devices are required to have the same parameters set

: baud rate, number of data bits, parity control, stop bits. e.g. 9600,8,N,1

– baud rate 9600 bit/s, data 8-bits, no parity control, 1 stop bit.

3. Barcode scanners can send additional information apart from the

expected barcode e.g. symbology (type of barcode). It is advisable

to disable such information because RADWAG devices and

software do not use it.

4. Some RADWAG systems can omit unnecessary information by

using parameters that mark the beginning and the length of the

code required to analyse.

5. A special protocol is required in order the code be received by

RADWAG equipment. It is required to program an appropriate

prefix and suffix. Prefix – one byte 01 hexadecimally, suffix one

byte 0D hexadecimally.

6. Most barcode scanners allow to enable/disable different

symbologies (barcode types).

7. Programming of scanners is usually performed by reading

special barcodes or by using an external software tool.

8. Scanners marketed together with RADWAG systems are

always configured according to the rules above.

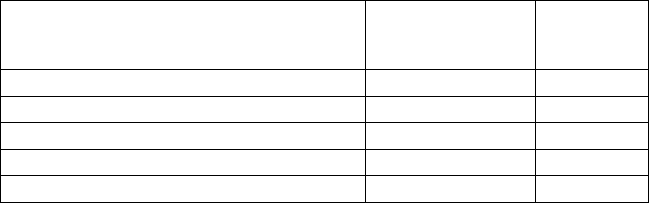

Barcode with required prefix and

suffix in hexadecimal format

Barcode without

required –fixes in

ASCII format

Code type

01 30 30 32 31 30 31 32 36 0D 00210126 EAN-8

01 30 31 32 33 34 35 36 37 38 39 0D 0123456789 2 of 5

01 43 4F 44 45 20 33 39 20 54 45 53 54 0D CODE 39 TEST CODE 39

01 31 31 30 31 32 33 34 35 36 37 38 39 31 0D 1101234567891 EAN-13

01 43 6F 64 65 20 31 32 38 20 54 65 73 74 0D CODE 128 Test CODE 128