Instruction Manual

Table Of Contents

- 1. INTENDED USE

- 2. PRECAUTIONS

- 3. WARRANTY CONDITIONS

- 4. MAIN DIMENSIONS

- 5. DESCRIPTON OF CONNECTORS

- 6. UNPACKING AND ASSEMBLY

- 7. GETTING STARTED

- 8. LOGGING ON

- 9. SCALE WINDOW DISPLAY

- 10. WEIGHING PROCEDURE

- 11. WINDOW NAVIGATION

- 12. PRODUCT CHOICE

- 13. CHOICE OF A CONTRACTOR

- 14. CHOOSING A PACKING

- 15. STORE CHOOSING

- 16. LOT CHOOSING

- 17. LOT 2 CHOOSING

- 18. QUANTITY NUMBER CHOOSING

- 19. DATABASES

- 20. COUNTING PIECES

- 21. TRANSACTIONS

- 22. STATISTICS

- 23. WEIGHING RECORDING

- 24. PROGRAMMABLE BUTTONS

- 25. LOGGING OFF

- 26. CHECKWEIGHING THRESHOLDS

- 27. PROGRAM’S OPTIONS

- 29. WEIGHING PARAMETRES SETTING

- 30. ERROR MESSAGES

- 31. LABEL DESIGNING

- 32. DIAGRAMS OF CONNECTION CABLES

- 33. CONNECTORS

- 34. SPECIFICATION OF ADDITIONAL MODULES

- 35. ADDITIONAL EQUIPMENT

- 36. TECHNICAL PARAMETERS

- 37. APPENDIX A – SETTING A BARCODE SCANNER

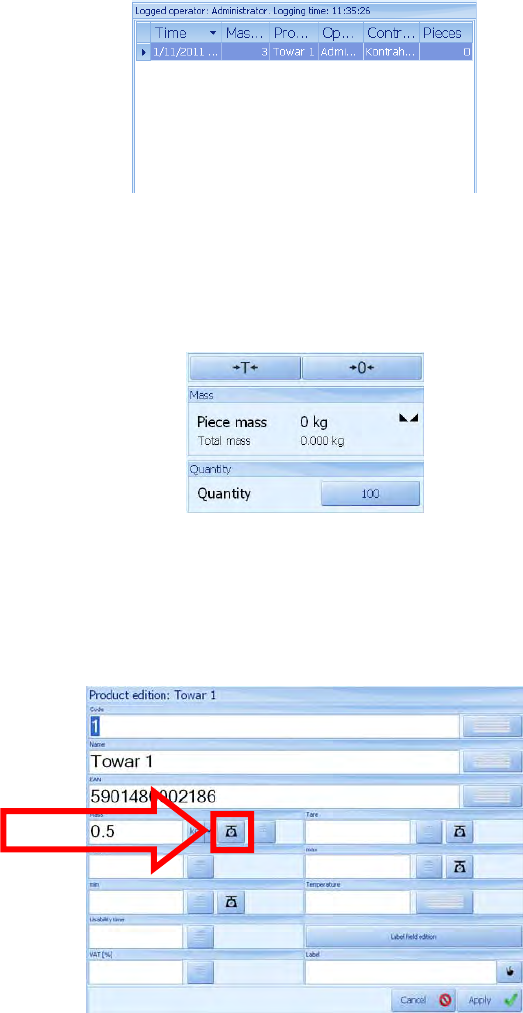

20.2. Setting reference unit mass

The reference unit mass can be set by estimating single piece mass in the

main program window using a function key attributed to this function.

Settings are described in ch. 27.5.2 of this manual.

After zeroing the platform put pieces on the pan and inscribe the quantity

in field Number of Pieces. Single piece mass is estimated automatically.

The reference unit mass can be also set in the assortment database. After

opening the window below press the button next to the mass field as shown

below.

- 45 -