Manual

LoadMate

®

LM05

STEPLESS I&M/EN/11.

30

.2010

51/71

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2010) R&M Materials Handling, Inc. All rights reserved.

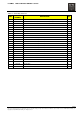

8.5 Troubleshooting

Table 10. Troubleshooting

PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTION

Hoist does not lift or lower load

Emergency stop button is

activated

Deactivate button

Blown fuse Replace the fuse

Motor thermal protection

activated

Allow motor to cool down

Pendant plug pin pushed out Reinstall plug pin

Contactor terminal screws loose Tighten screws

Inverter terminal is badly fixed Press on the terminal

Mainline switch shut off Turn switch on

Hoist does not lift load Overload condition Reduce load

Slip clutch worn or incorrectly

adjusted

Replace wear items or readjust

slip clutch torque

Upper limit switch is activated Adjust

Load drifts more than 4 inches

[100mm] during an emergency

stop

Brake lining worn

Adjust the brake slipping clutch

and replace the slipping clutch

components if necessary.

Travel direction does not

correspond to that indicated on

push button

Connections of the pendant are

incorrect.

Change wiring of pendant.

Abnormal noises while lifting or

lowering

Load chain and its components

are not lubricated

Clean and lubricate load chain.

Load chain is worn Replace chain

Chain wheel or chain guide is

worn

Replace chain wheel or chain

guide

Idler sprocket is worn Replace idler sprocket

A supply phase is missing Connect the three phases

Twist or kink in load chain Remove twist or kink

Slow down distance is too long Wrong inverter setting

Adjust slow down at inverter

level