User's Manual

Table Of Contents

- Contents

- Figures

- Tables

- Preface

- Tape Drive Product Information

- SDLT 600 Tape Drive Specifications

- Installing Your Tape Drive

- Warranty Note

- Safety, Handling, and ESD Protection

- Pre-Installation Guidelines

- Configuring and Installing an Internal Tape Drive with SCSI Interface

- Configuring and Installing an Internal Tape Drive with Fibre Channel Interface

- Configuring and Installing a Tabletop Tape Drive with SCSI Interface

- Configuring and Installing a Tabletop Tape Drive with SCSI Interface

- Confirming the Installation

- Using Your Tape Drive

- Regulatory Compliance

- Super DLTtape I and Super DLTtape II Data Cartridges

- DLTtape VS1 Data Cartridge

- Glossary

Data Cartridge Inspection Procedure

SDLT 600 Product Manual 110

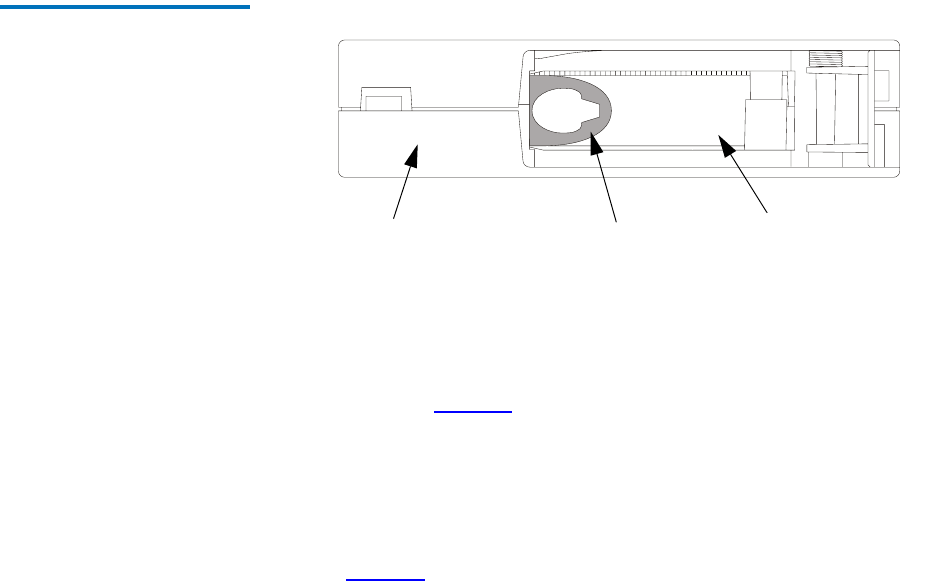

Figure 32 End View of DLTtape

VS1 Data Cartridge (Tape

Leader Loop in its Correct

Position)

10 Inside the door, you will see the media and tape leader loop. The loop

should stick up about an eighth of an inch when viewed from the

edge; the loop must be a closed loop.

11 Examine the visible tape leader to ensure it is in the correct position

as shown in figure 32

. If the loop is torn, bent, pulled in, or not sticking up

about an eighth of an inch, do not use the data cartridge.

12 Examine the tape leader for any excessive debris, oily or sticky

residue, condensed droplets of moisture, or any other signs of

contamination.

Compare what you see inside the data cartridge door to illustrations

in figure 33

. Look for faulty items including:

• A broken tape leader loop

• A swallowed tape leader loop

• Loose media inside the data cartridge.

Do not use a data cartridge that exhibit any of the type of problems

shown in these examples.

Data Cartridge

Tape Leader Loop

Media