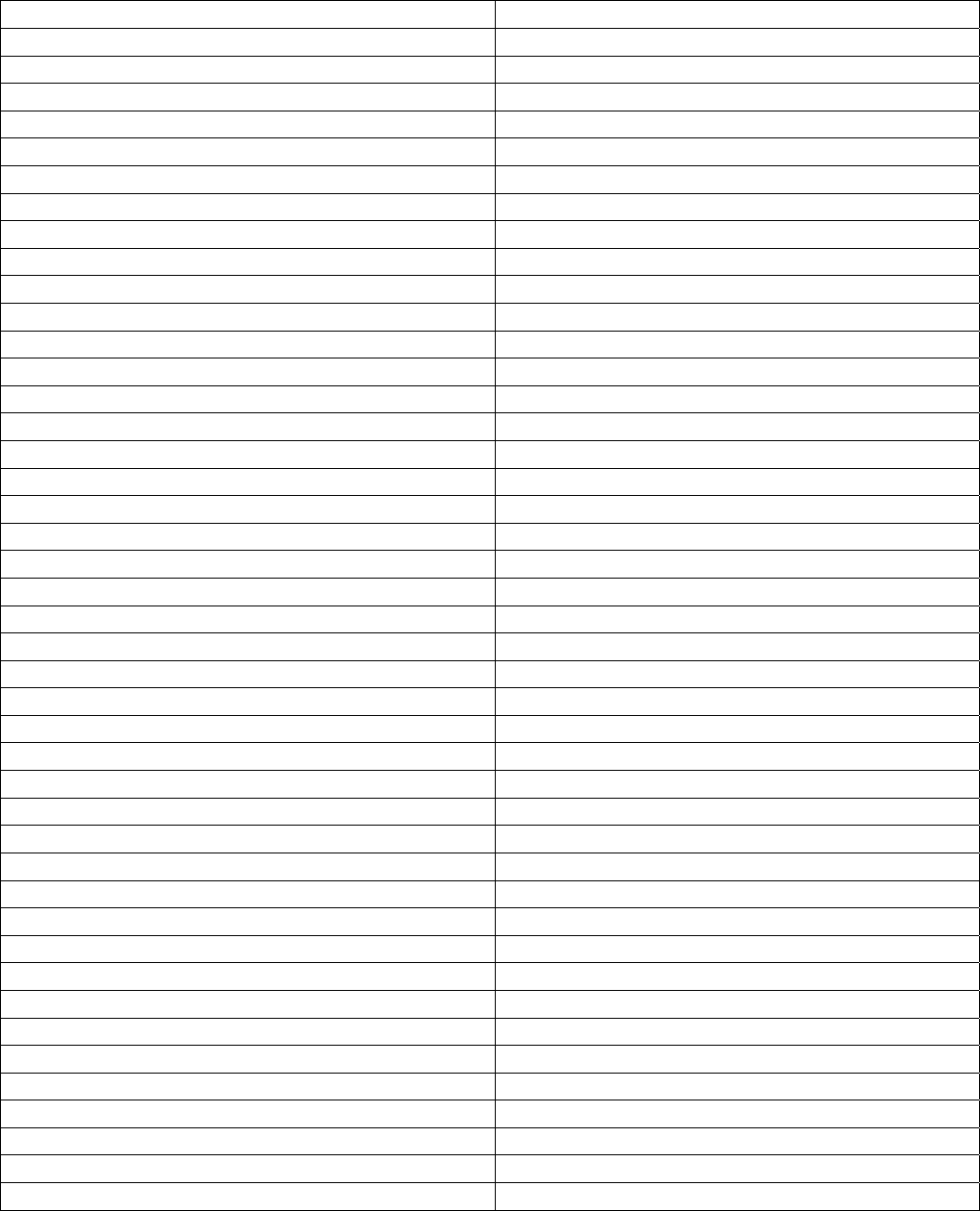

Specifications

74

Film

Typical problems, Follow list for topic in sequence, the first solution will be the most common.

Film is foggy, on rollers and in lamination Decrease speed

Increase temperature

Defective Film

Film is foggy, clear on rollers foggy in lamination Decrease temperature

Defective Film

Film does not stick / poor adhesion Decrease speed

Increase temperature

Increase roller Pressure

Incompatible film adhesive with project

Defective Film

Bubbles / air pockets in film only, not near edge Film is not running flat at nip, increase tension

Film is not running flat at nip, decrease tension

Not enough pressure for application, increase

To much pressure (rollers bending), decrease

Defective Film

Bubbles / air pockets in lamination See troubleshooting for film

Defective Film

Bubbles in edge seal Not enough pressure available, increase

Paper to thick for film / laminator

Speed to great to conform, Slower

Temperature to low for adhesive flow, increase

Film to thin for adhesive flow

Bubbles between sheets perpendicular to rollers Not enough pressure available, increase

To much pressure (rollers bending), decrease

Film to thin for adhesive flow

Temperature to low for adhesive flow, increase

Sheets to close, allow more space

Bubbles in edge seal parallel to the rollers Too hot, decrease temperature

Blistering / random bubbles on paper Too hot, decrease temperature

Paper moisture content too high

Incompatible film / temperature for the ink used

Defective Film

Optical distortion in film / wavy / puddles Too hot for film base, decrease temperature

Too slow – Film base distorting, speed up

Too Much Pressure, decrease

Defective Film

Optical distortion in film parallel to rollers Motor pulsating, increase speed

Motor pulsating, reduce mandrel tension

Supply roll bouncing, increase mandrel tension

Film stretching and rebounding, decrease tension

Roller pressure too great, reduce

Irregular bonding Decrease speed

Increase roller pressure

Defective Film