Use And Care Manual

Check with a qualied electrician or service technician

if the grounding instructions are not completely understood,

or if in doubt as to whether the tool is properly grounded.

Use only three-wire extension cords that have three-prong

grounding plugs and three-pole receptacles that accept the

tool's plug, as shown in Fig. 1. Repair or replace a damaged

or worn cord immediately.

Improper connection of the equipment-grounding conductor

can result in a risk of electric shock. The conductor with

a green outer surface, with or without yellow stripes, is the

equipment-grounding conductor. If repair or replacement

of the electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Do not modify the plug provided. If it will not t the outlet,

have the proper outlet installed by a qualied electrician.

an electric cord having an equipment-grounding conductor

and a grounding plug. The plug must be plugged into

a matching outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING: LASER LIGHT. LASER RADIATION.

Avoid direct eye exposure. Do not stare into the beam. Only

turn the laser beam on when the laser will shine on a work

piece.

laser light. Be aware of the laser light location when using

the tool. Always make sure that any bystanders in the

vicinity of use are made aware of the dangers of looking

directly into the laser.

WARNING: Use of controls, adjustments or

performance of procedures other than those specied in

this manual may result in hazardous radiation exposure.

SAFETY INSTRUCTIONS

Page 7

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped with

GROUNDING INSTRUCTIONS

• The laser should be used and maintained in accordance

with the manufacture’s instructions.

• Never aim the beam at any person or any object other

than the work piece.

• Always ensure that the laser beam is aimed at a sturdy

work piece without a reective surface. Wood or

roughcoated surfaces are acceptable. Bright, shiny

reective surfaces are not suitable for laser use, because

the reective surface could reect the beam back at the

operator.

• Do not attempt to activate the laser when the tool housing

is removed.

• The laser is activated with a button switch that is

independent of the main switch for the drill press.

• Do not replace the laser guide assembly with a different

type. Any repairs must be carried out by the laser

manufacturer or a qualied service technician.

• Do not attempt to repair the laser guide by yourself.

• Do not attempt to change any parts of the laser guide.

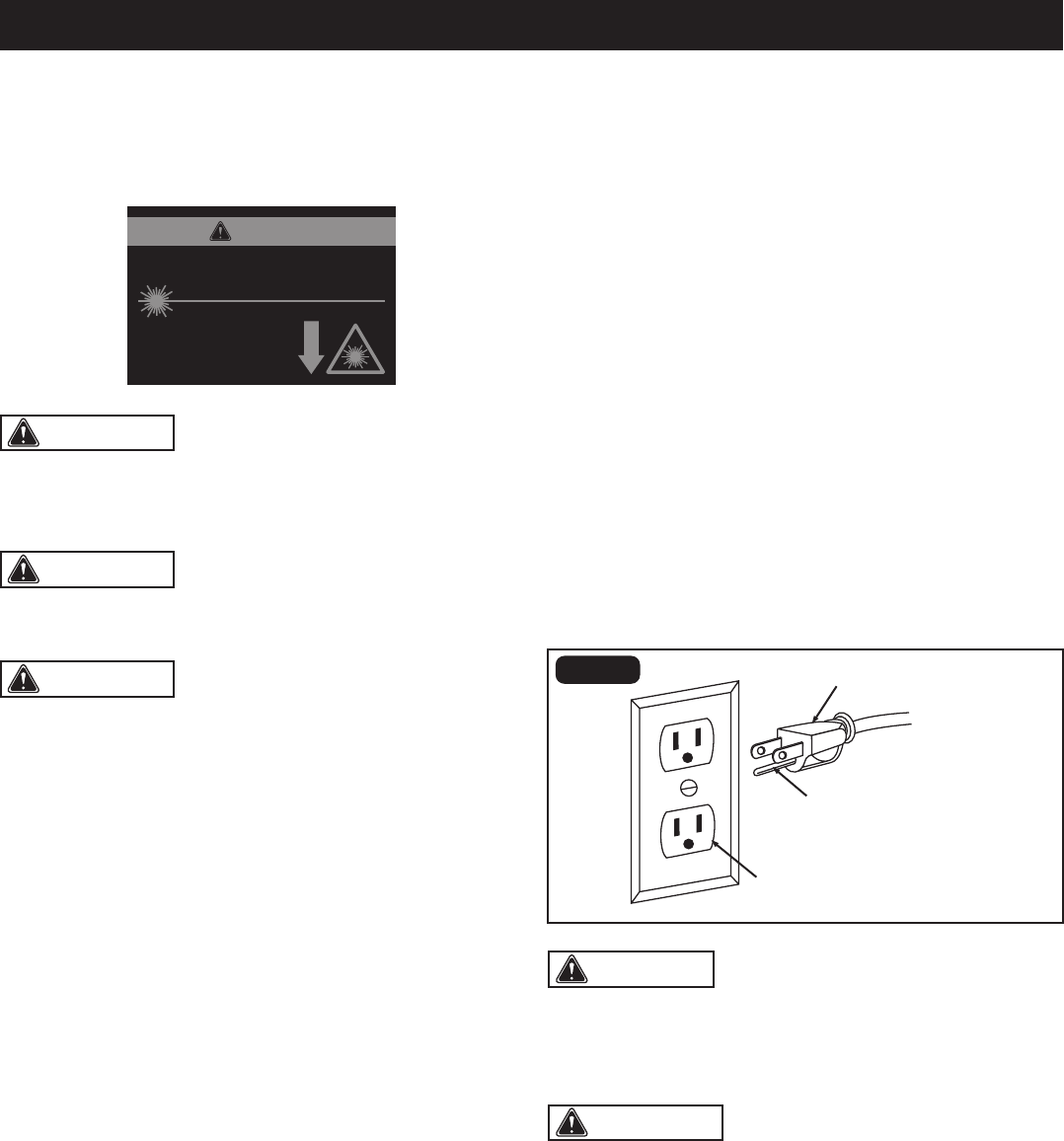

CAUTION: In all cases, verify that the outlet in

question is properly grounded. if you are not sure, have a

licensed electrician check the outlet.

FIG. 1

This tool has a precision-built electric motor. It should be

connected to a power supply that is 120 volts, 60 Hz. A

substantial voltage drop will cause a loss of power and the

motor will overheat. If the tool does not operate when plugged

into an outlet, double check the power supply.

ELECTRICAL CONNECTION

WARNING: Do not permit ngers to touch the

terminal or the plug when installing or removing the plug

from an outlet.

Three-prong plug

Grounding prong

Properly grounded outlet

WARNING: The use of optical instruments to view

the laser beam, including but not limited to telescopes or

transits, will increase eye hazard.

LASER RADIATION. DO NOT STARE INTO BEAM OR

VIEW DIRECTLY WITH OPTICAL INSTRUMENTS.

Avoid exposure: Laser radiation

is emitted from this aperture.

Wavelength: 650 nm Max. Output < 1 mW

Class II Laser Product Complies with 21

CFR 1040.10 & 1040.11

CAUTION