Use And Care Manual

Page 20

WARNING:

• To reduce the risk of injury, only use the chuck key

provided with this drill press or a duplicate of it. This chuck

key is self-ejecting and will “pop” out of the chuck when

you let go. This action is designed to help prevent throwing

of the chuck key from the chuck when power is turned

“on”. Do not use any other key as a substitute; order a

new one if damaged or lost.

• To reduce the risk of injury, make sure the chuck key is

removed from the chuck before starting any drilling

operation.

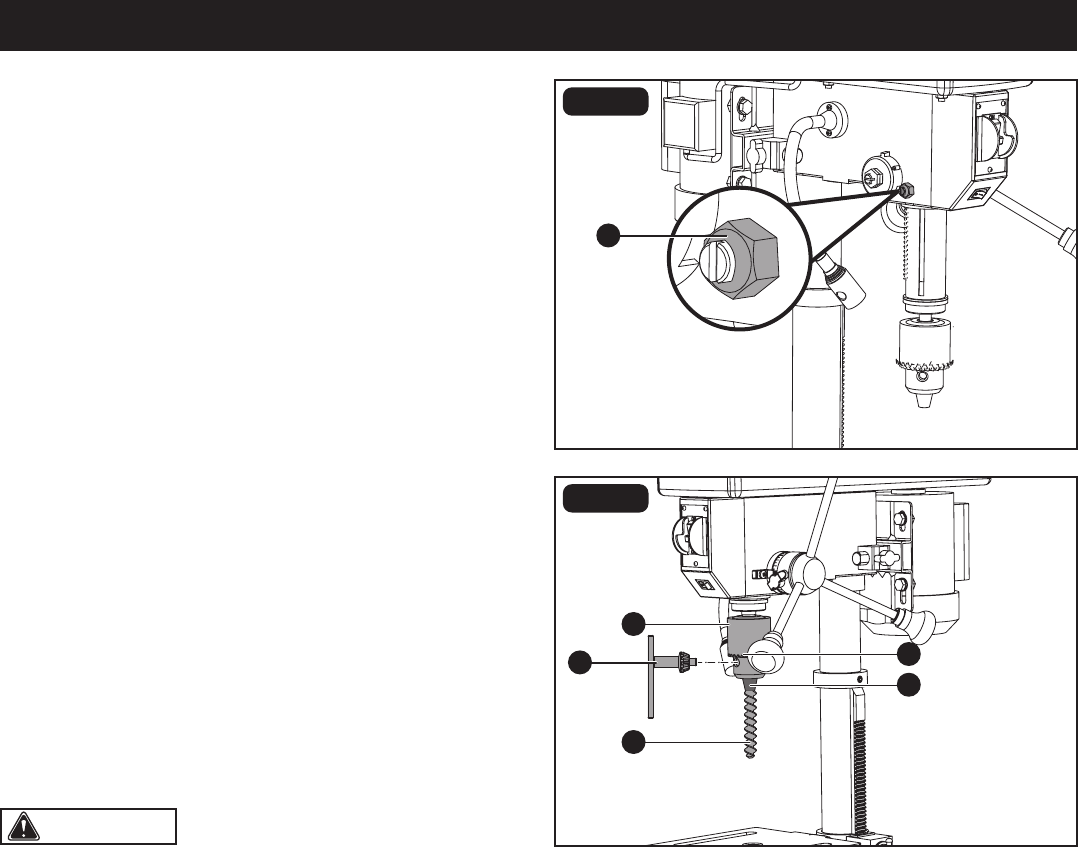

A

A

E

B

D

C

FIG. 17

ADJUSTMENTS

ANGULAR PLAY OF THE SPINDLE

(Fig. 17)

Move the spindle to the lowest downward position and hold

in place. With your other hand, try to make it revolve around

its axis with a side motion. If there is too much play, proceed

as follows:

• Loosen the lock nut (A).

• Turn the screw clockwise to eliminate the play but without

obstructing the upward and downward motion of the

spindle (a little bit of play is normal).

• Tighten the lock nut (A).

FIG. 18

INSTALL DRILL BITS (Fig. 18)

• Place the chuck key (A) into the side keyhole of the chuck

(B), meshing the gear teeth (C).

• Turn the chuck key counter-clockwise to open the chuck

jaws (D).

• Insert a drill bit (E) into the chuck far enough to obtain

maximum gripping of the chuck jaws.

• Centre the drill bit in the chuck jaws before nal tightening

of the chuck.

• Use the chuck key for the nal tightening to make sure

the drill bit will not slip while drilling.