Use And Care Manual

RPM 60Hz∞620

BELT: A-1

E

D

C

B

A

5

4

3

2

1

E

D

C

B

A

5

4

3

2

1

E

D

C

B

A

5

4

3

2

1

E

D

C

B

A

5

4

3

2

1

E

D

C

B

A

5

4

3

2

1

BELT: B-2 BELT: C-3 BELT: D-4 BELT: E-5

RPM 60Hz∞1150 RPM 60Hz∞1630 RPM 60Hz∞2180 RPM 60Hz∞3070

1 2 3 4 5

ADJUSTMENTS

CAUTION: The belt (D) should be tight enough to

prevent slippage. Correct tension is set if the belt exes

about 1/2 in. (13 mm) when thumb pressure is applied at

the midpoint of the belt between the pulleys.

Page 17

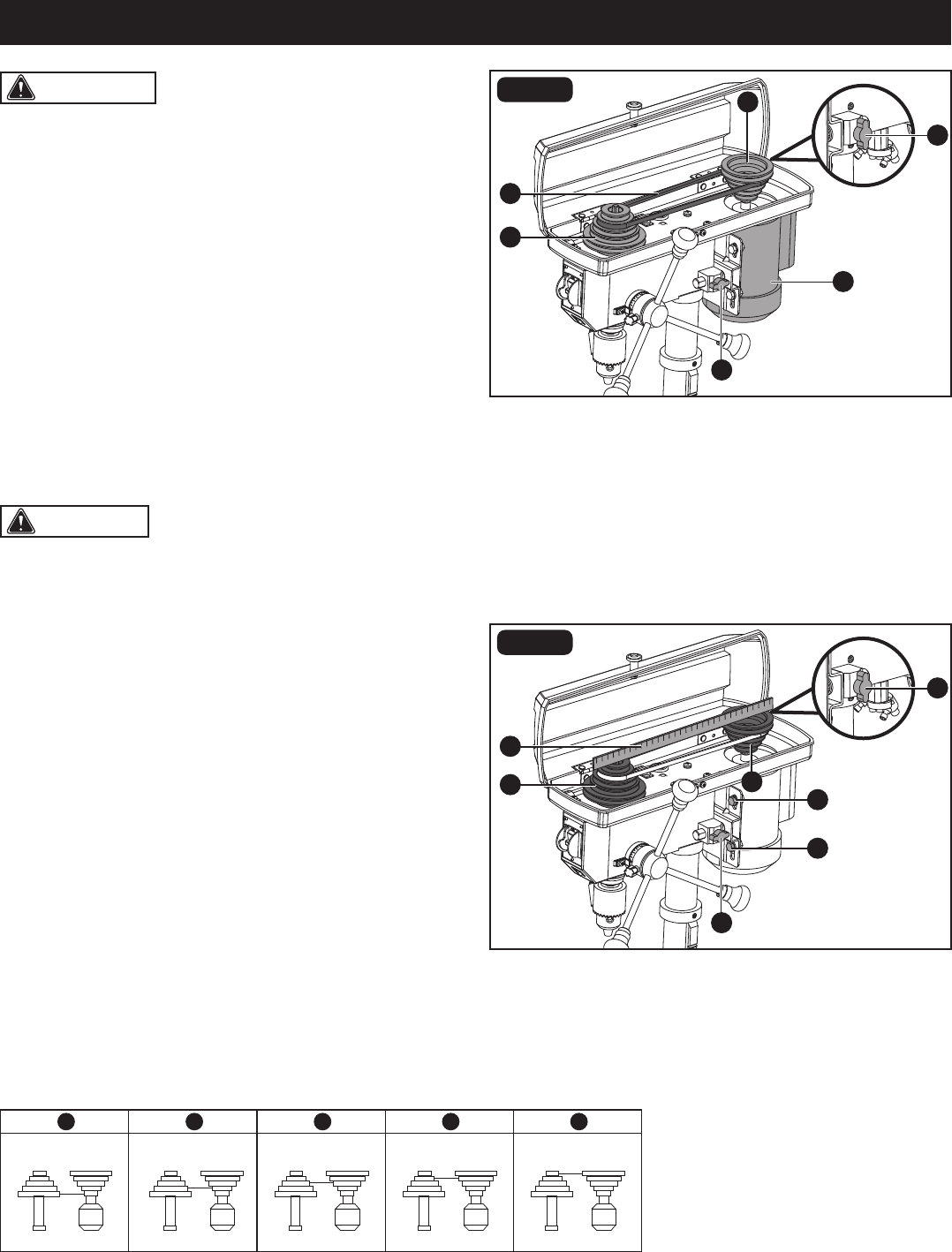

INSTALL THE BELT (Fig. 9)

ASSEMBLY ADJUSTMENTS

• Open the pulley housing cover.

• Loosen the belt tension lock knobs (A) on both sides of

the drill press.

• Slide the motor (B) as close to the drill press head

as possible.

• Place a belt (C) on the motor pulley (D) and the spindle

pulley (E) in the proper position for the desired speed.

• Pull the motor away from the drill press head until the belt

is properly tensioned. Tighten the belt tension lock knobs

(A).

ALIGN THE BELT PULLEYS (Fig. 10)

• Check the alignment of the pulleys with a straight edge

of ruler (A) by laying the straight edge across the top of

the motor pulley (B) and spindle pulley (C).

• If the pulleys are NOT aligned, release belt tension

by loosening the belt tension lock knobs (D) on both sides

of the head.

• Loosen the motor mount nuts (E) with an adjustable

wrench or 13mm open-end wrench, and lower or raise the

motor until the pulleys are aligned.

• Tighten the motor mount nuts (E) with an adjustable

wrench or 13mm open-end wrench to maintain the

position.

• Lock the motor for the proper belt tension and tighten the

tension lock knobs (D).

WARNING: To prevent personal injury, always

disconnect the plug from the power source when making

any adjustment.

B

A

D

E

C

A

FIG. 9

D

B

C

A

D

E

E

FIG. 10

SPINDLE SPEEDS

This drill press offers ve spindle speeds from 620 to 3070 RPM. The highest speed is obtained when the belt is positioned

on the largest motor pulley step and the smallest spindle pulley stop.