PureFire PFA-1 Interface Adaptor Installation, Operation, and Maintenance Manual

2. Analog Input of Rate:

Input voltage below 2 volts dc will disable boiler

operation. 2 volts corresponds to minimum boiler

input which will display as 1% Input on the RC

Display (see boiler manual for minimum input

ratings). 10 volts corresponds to maximum boiler

input, and voltages in between will linearly adjust the

input rate.

G. OPERATION – MODBUS INTERFACE

1. Modbus Configuration:

The table below summarizes the Modbus

configuration details:

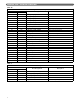

2. Modbus Holding Registers:

Modbus communicates using “words” (the contents of

16 bit holding registers). The PFA-1 Interface Adapter

organizes the data in read-only holding registers. Table

2 shows the information that is available for reading

and the address of the holding registers. Depending on

the type of Modbus software used, the holding register

addressing range starts at either 0x0000 or 0x0001.

The values of STATE and ERROR_NUMBER can

be used to determine whether the boiler control is

operating correctly, not communicating or in an

error state.

PUREFIRE PFA-1 INTERFACE ADAPTER

Table 2

Table 1

Modbus Configuration Specifications

Protocol Modbus RTU

Default Address 0x01 (settable with SiteVision)

Supported Commands

• Read Holding Registers (0x03)*

• Write single holding register (0x06)

Baud Rate 9600 bps

Data Length 8 bits

Parity None

Stop Bits 1

Physical Layer RS485 (2 wire)

Modbus 1 A Connection J7-1

Modbus 1 B Connection J7-3

Buffer Size

8 registers per frame

Modbus Holding Registers (Read Only)

Item Index

Parameter Name

Address & Holding Registers

Notes

Word byte

Range Start

0x0000

Range Start

0x0001

0 High byte 0 STATE 0x0000 0x0001 See Table 3

0 Low byte 1 STATUS 0x0000 0x0001 See Table 4

2 High byte 2 ERROR_NUMBER 0x0002 0x0003 See Table 6

2 Low byte 3 WARNING_NUMBER 0x0002 0x0003 See Table 7

4 High byte 4 FLOW_TEMP* 0x0004 0x0005

°C=byte value

2

–10

°F=°Cx9

5

+32

4 Low byte 5 RETURN_TEMP 0x0004 0x0005

6 High byte 6 DHW_TEMP 0x0006 0x0007

6 Low byte 7 FLUE_TEMP 0x0006 0x0007

8 High byte 8 NOT USED 0x0008 0x0009

8 Low byte 9 NOT USED 0x0008 0x0009

10 High byte 10 APPLIANCE_TYPE 0x000A 0x000B

—

10 Low byte 11 CONTROL_CONFIG_BYTE 0x000A 0x000B

—

12 High byte 12 CH_MODE 0x000C 0x000D

—

12 Low byte 13 DHW_MODE 0x000C 0x000D

—

14 High byte 14 CH_SETPOINT 0x000E 0x000F

—

14 Low byte 15 DHW_SETPOINT 0x000E 0x000F

—

* FLOW_TEMP is the boiler supply (outlet) water temperature.

To read these values, issue a Modbus command to read a holding register. For example, if a command is issued to read

0x0000 the resulting, unsigned word may read, “0x090F”. The high byte for this word is “0x09”. Table 3 shows that this value

indicates that the burner is on. The low byte for this word is “0x0F”. This indicates that the boiler is on as a result of the freeze

protection algorithm as shown in Table 4.

3