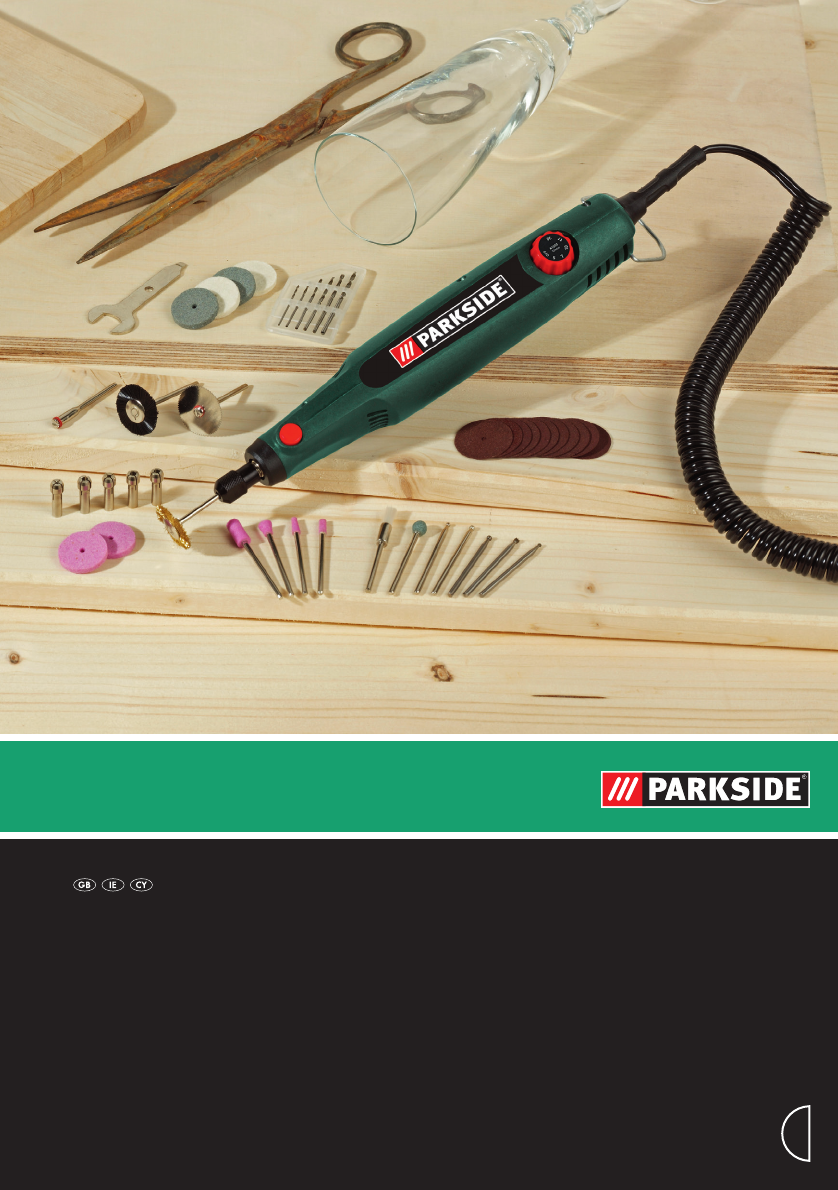

PMGS 12 MODELLING AND ENGRAVING SET Operation and Safety Notes 6 33382_MODELLING AND ENGRAVING SET_Cover_LB6.indd 2 24.07.

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions of the device. GB / IE / CY Operation and Safety Notes 33382_MODELLING AND ENGRAVING SET_Cover_LB6.indd 3 Page 5 24.07.

5 6 1 4 2 3 A 7 8 9 B 11 23 12 22 13 21 14 20 15 16 19 18 17 10 C D E F G H 33382_MODELLING AND ENGRAVING SET_Cover_LB6.indd 4 24.07.

Table of contents Introduction Proper use.......................................................................................................................Page Features and equipment................................................................................................Page Included items................................................................................................................Page Technical information......................................................................

Introduction The following pictograms are used in these operating instructions / on the device: V~ W n0 Read instruction manual! Keep children away from electrical power tools! Volt (AC) Caution – electric shock! Danger to life! Watts (Effective power) For indoor use only! Direct current (Type of current and voltage) Risk of loss of life by electric shock from damaged mains lead or mains plug! Design no-load speed Wear hearing protection, dust protection mask, protective glasses and protective gl

Introduction / General safety advice for electrical power tools Mains adapter (see Fig. A): 7 Plug-in device for plug 3 8 Tray 9 Mains adapter 10 Power cable (with mains plug) Accessories (see Fig.

General safety advice for electrical power tools MEANS OF A MAINS LEAD) AND ELECTRICAL TOOLS POWERED BY RECHARGEABLE BATTERIES (WITHOUT A MAINS LEAD). 1. Workplace safety a) Keep your working area clean and well lit. Untidy or poorly lit working areas can lead to accidents. b) Do not work with the device in potentially explosive environments in which there are inflammable liquids, gases or dusts. Electrical power tools create sparks, which can ignite dusts or fumes.

General safety advice for electrical power tools you will be in a better position to control the device in unforeseen circumstances. f) Wear suitable clothing. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves clear of moving parts. Loose clothing, jewellery or long hair can become trapped in moving parts. g) If vacuum dust extraction and collection devices are fitted do not forget to check that they are properly connected and correctly used.

General safety advice for electrical power tools / Operation J Warning! DUST HAZARD! Any harmful / noxious dusts generated from machining represent a risk to the health of the person operating the device and to anyone near the work area. Wear a dust mask! J Warning! NOXIOUS FUMES! Ensure that there is adequate ventilation when machining surfaces containing plastic or covered with paint, varnish etc. J Do not soak the materials or the surface you are about to work on with liquids containing solvents.

Operation Switching off: j Set the On / Off switch 1 to position “0”. Q Advice on working with materials / Tools / Speed ranges j Use the highest speed when working on steel or iron with the milling bits 20 . j Use a short trial on a test piece to determine the optimum rotational speed range for working on zinc, zinc alloy, aluminium, copper and lead. j Use the low speed range for working on plastics and low-melting point materials. j Use high speeds on wood.

Operation / Maintenance and cleaning / Service / Warranty / Disposal Q Maintenance and cleaning The device is maintenance-free. j Clean all the dirt off the drill / grinder. Use a dry cloth for cleaning. Q Service J Warning! Have your device repaired at the service centre or by qualified specialist personnel using original manufacturer parts only. This will ensure that your device remains safe to use.

Manufacturer’s Declaration of Conformity / Manufacturer Q Manufacturer’s Declaration of Conformity / Manufacturer We, Kompernaß GmbH, Burgstr. 21, D-44867 Bochum, Germany, declare that this product complies with the following EU directives: Machinery Directive (98 / 37 / EC) EU Low Voltage Directive (2006 / 95 / EC) Electromagnetic compatibility (2004 / 108 / EC) Type / Device description: Modelling and engraving set PMGS 12 Bochum, 31.07.

IAN 33382 KompernaSS GmbH Burgstraße 21 D-44867 Bochum © by ORFGEN Marketing Last Information Update: 07 / 2009 · Ident.-No.: PMGS12072009-6 33382_MODELLING AND ENGRAVING SET_Cover_LB6.indd 1 6 24.07.