User manual

Table Of Contents

- Title page

- New in this release

- List of Procedures

- How to get help

- Finding the latest updates on the Nortel web site

- System information

- Introduction

- Preparing for installation

- Placing the fourth module on a column

- Positioning and leveling equipment

- Installing AC power

- Installing overhead cable tray kits

- Installing DC power

- Contents

- DC-powered systems

- Candeo DC power systems

- Large Candeo modules

- Small Candeo modules

- Installation reference guide

- Configuration reference guide

- Safety ground/protective earth and logic return wiring

- Cabling and connecting the grounding leads

- Connecting the power plant frame ground (or safety ground) leads

- Four-Feed PDU

- Installing the Four-Feed PDU

- Installing safety ground/protective earth wiring

- Connecting power from the power plant to the PDU

- Connecting UK power to the Four-Feed PDU

- System monitor connections

- Planning and designating a Main Distribution Frame

- Installing Power Failure Transfer Units

- Configuring the system monitor

- Connecting a system terminal or modem

- Contents

- About the system terminal

- Connecting a terminal

- Connecting a terminal to a COM port

- Connecting a switch box and terminal to COM1 and COM2 ports

- Connecting a switch box and terminal to SDI and COM1 ports

- Connecting a modem

- Configuring a modem

- Connecting a modem to an SDI port

- Connecting a modem to switch box, COM2 ports, SDI ports

- Cabling Common Equipment in a Single Group system

- Contents

- Cabling guidelines

- Core/Net module

- Cabling the Core side

- Cabling the I/O panel

- Cabling the Network side

- Configuring and cabling the Clock Controllers

- Network Group 0: Shelf 0 to Shelf 1

- Connecting the 3PE faceplates in the Core/Net modules

- Inspecting CNI to 3PE factory installed cables

- Connecting the Core/Net backplanes

- Optioning the System Utility Card

- Connecting Core modules to a LAN

- Cabling Common Equipment in a Multi Group system

- Contents

- Cabling guidelines

- Core/Net module

- Cabling the Core/Net module backplane

- Disconnecting cables from the Core/Net module backplane

- Optioning the System Utility Card

- Core shelf cabling

- Installing the CP PIV to I/O panel cables

- Connecting the Core module to a LAN

- Cabling a Dual Ring Fiber Network

- FIJI card cabling

- Installing the Shelf 0 fiber optic ring (ascending)

- Installing the Shelf 1 fiber optic ring (descending)

- FIJI to FIJI cabling

- Connecting the Clock Controller cables

- Cabling network modules and loops

- Contents

- Network-to-network cabling

- Network module connections

- Network Group 0: Shelf 0 to Shelf 1

- Connecting the 3PE faceplates in the Core/Net modules

- Connecting the Core/Net backplanes

- Connecting Groups 1 through 7: Shelf 0 to Shelf 1

- Connecting the Network modules to the Core/Net modules

- Connecting the 3PE cables to the 3PE fanout panels

- Cabling a Superloop Network Card - single column

- Cabling a Superloop Network Card - multiple columns

- Cabling lines and trunks

- Powering up the system and initial loading

- Performing acceptance tests

- Installing earthquake bracing

- Adding a module to a column

- Installing a Signaling Server

- Contents

- Introduction

- Readiness checklist

- Installing the CP PM Signaling Server hardware

- Connections

- Installing the Signaling Server software

- First boot of a new Nortel CP PM Signaling Server

- Unpacking Help files for Virtual Terminal Emulator

- Logging in to the Signaling Server

- Verifying a successful configuration

- Testing the Leader Signaling Server

- Index

Page 348 of 458 Installing earthquake bracing

NN43021-310 Standard 02.02 October 2008

Next, each column must also be secured to the floor. This is accomplished by

installing one of two available anchor kits. Select the anchor kit by comparing

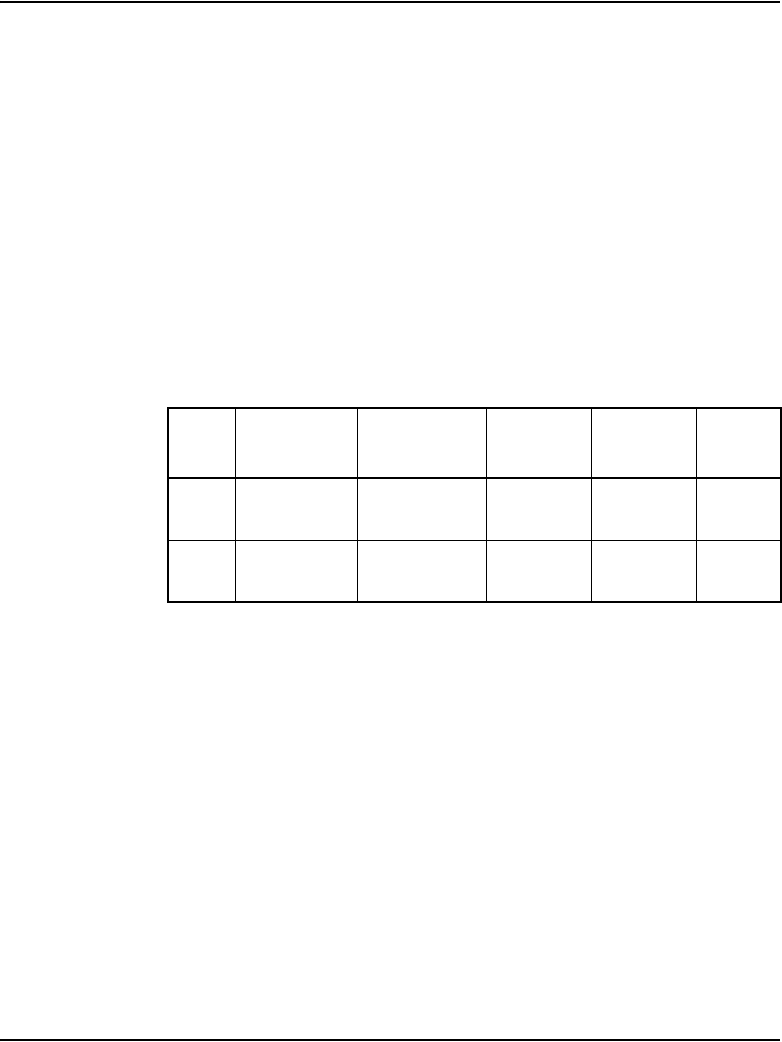

the site requirements to Table 62 on page 348. This table shows that either

anchor kit can be used to meet the CALIFORNIA OSHPD specification, but

only Kit B meets the BELLCORE specification. For those installations where

neither specification is required, Kit A is recommended due to its shallower

concrete requirement.

Both anchor kits can be used in hardrock concrete as long as the compressive

strength exceeds 20.7 MPa (3000 psi). Only Kit A can be used in lightweight

aggregate concrete with a compressive strength greater than 27.6 MPa

(4000 psi). The floor parameters for your installation can usually be found in

the engineering building drawings.

The kits listed in Table 62 on page 348 contain commercially available

mounting hardware. You have the option of purchasing the contents directly

from the manufacturer (using the listing below) or ordering the kits directly

from Nortel.

• Kit A (NT8D64BE) contains four of each of the following items:

— Hilti HDI 3/4 in., box of 25, manufacturer part # 457564 (Hilti

Corporation (918) 252-6000) or Multi-Set II, manufacturer

part # RM-34 (ITW Ramset/Redhead, Incorporated (219)

874-4217)

— Hex head bolt, 3/4 in. -10 x 1.50” long, steel material, zinc plate

finish

Table 62

Seismic Anchor Kit

Kit

Seismic

Anchor Kit

BELLCORE

CAL

OSHPD

Concrete

thk (min)

Light-

weight

A NT8D64BE No Yes 90 mm

(3.5 in.)

Ye s

B NT8D64CE Yes Yes 180 mm

(7 in.)

No