User Manual

38 Troubleshooting

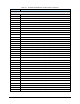

Table 7-3 DJ-9500 Troubleshooting – Component Based

Component Quality Troubleshooting Questions

Seat

Size and

orientation

Is it the correct size? Was it installed in the correct orientation? Does

a new seat have the same behavior?

Nozzle

Size and

cleanliness

Is it the correct size? Was it cleaned completely? Does a new nozzle

have the same behavior?

Stroke

Adjustment

Adjustment

position

Was the Stroke Adjustment Assembly removed? Was the stroke

adjustment set following the procedure? Is the Needle Assembly

worn or damaged?

Retainer

Assembly

Installation

Was a repeatable process used to re-assemble the jet? Was the

retainer firmly tightened? Was the stroke adjustment open to the red

mark when tightened?

Chamber O-

ring

Condition

Was the seal damaged during cleaning? Was the seal replaced?

Does a new seal have the same behavior?

Fluid Seal

Condition

and

Orientation

Is the seal worn or damaged? If being reused, was it cleaned

completely? Was the seal removed/installed using the seal tool (P/N

7201416)? Was it installed in the correct orientation?

Solenoid Operation

Are the electrical connections good – both at the bulkhead and in the

junction box? Is a minimum of 80-psi air being supplied all the way to

the solenoid inlet? Is the solenoid armature actuating (faint ticking)?

Can the solenoid open using the manual override? Is air exiting the

solenoid when operated?

Needle

Assembly

Condition

Is the needle assembly worn or damaged? Check the tip, fluid seal

location and the piston seal. Does the needle assembly move freely

in the jet body with the stroke adjustment assembly removed?

Thermal

Control

Assembly

(TCA)

Operation

Is the heater turned on? Is the heater set to the right temperature?

Does the resistance across the heater and RTD leads meet

specification? Are the heater and RTD leads insulated from the TCA

body? Does cooling air pass through the TCA body? Is the cooling

airflow set properly?

Body Heater Operation

Is the heater turned on? Is the heater set to the right temperature?

Does the resistance across the heater and RTD leads meet

specification? Are the heater and RTD leads insulated from the

body? Does cooling air pass through the Junction Box and Heat

Exchanger body? Is the cooling airflow set properly?