User Manual

Troubleshooting 37

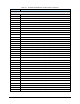

Table 7-2 DJ-9500 Troubleshooting – Set-up Based

Set-up Variable Effect Notes

Fluid

Properties

Dispense

Volume and

Quality

If this is a new process, contact Nordson ASYMTEK for

assistance in process development. If this is a qualified process,

fluid properties may have changed. The fluid may have

exceeded its pot life, or been mishandled or set-up incorrectly.

In addition, air bubbles are a common problem in mixed, high

viscosity fluids. Improper thawing can introduce air to the fluid

supply, which results in intermittent shots. De-gas the fluid if

possible in a vacuum chamber.

Fluid Pressure

Dispense

Volume

Verify that the fluid supply has been set up correctly and that

fluid is free to flow to the jet chamber. Verify the pressure setting

is correct. Insufficient fluid pressure results in small shot

volumes or no shots. Too much fluid pressure leads to larger

shot volumes.

Valve Pressure

Dispense

Volume

Needle assembly travel is affected by valve pressure. Lower

valve pressure increases jet reaction time. In high duty-cycle

applications, sufficient valve pressure is required to meet

performance specifications.

TCA

Temperature

Dispense

Volume and

Quality

Typically, higher temperatures lead to decreased fluid viscosity

and a higher fluid flow rate. Test the sensitivity of the fluid to a

small temperature change. Verify the Temperature Control

Assembly – TCA, is holding at the desired temperature through

the Fluidmove Temperature Control Window.

Both the heater element and RTD are 2-wire devices. Failure

modes include “open” and “short”. The “open” mode occurs

when either of the two wires is broken. The “short” mode occurs

when there is zero resistance across the two wires, or between

either wire and the TCA body.

Cooling occurs by circulating compressed air through the TCA.

Check that adequate air pressure is present at the transparent

green pneumatic line, and that the coolant passage is

unobstructed.

Body

Temperature

Dispense

Volume and

Quality

The body temperature is usually set to the same temperature as

the TCA temperature.

Cooling occurs by circulating compressed air through the body.

Check that adequate air pressure is present at the green

pneumatic line, and that the coolant passage is unobstructed.

Jet On/Off

Time

Dispense

Volume

The time the solenoid control signal is held on is termed “On

Time”. The time between “On” signals is termed “Off Time”.

On/off times that are too small will not allow the needle

assembly to fully open or fully close. On times set too large may

cause excess fluid to flow through the jet.

Dispense Gap Dispense Quality

A jet with the dispense gap set too low will “plow” through the

dispensed fluid and accumulate fluid on the nozzle tip. Dispense

gaps set too high will result in poor shot shape with a higher

frequency of dispense “satellites.”