Instruction Manual

Introduction 2-7

Power ON and OFF

The Start and Stop buttons are located on the Control Panel and control the power to the

dispensing system. The Start and Stop buttons are momentary press down buttons. The Start

button illuminates in green when pushed and remains illuminated until the Stop button or

EMO is pressed. When the stop button is pressed, the dispensing activity shuts down. (The

computer and monitor have their own power switches and are not affected.)

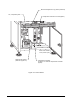

Process Control Cover

The Process Control Cover consists of a stainless steel shroud adjacent to the heated

vacuum tooling plate in the dispensing area. The Process Control Cover protects sensitive

instrumentation such as the Digital Scale weigh station, purge station, and needle sensor

from inadvertent dispensing fluid spills and work area mishaps.

Purge Station

The Purge Station is a small reservoir that contains a disposable plastic cup. A generator

produces a vacuum inside the reservoir. The dispensing nozzle or needle is inserted into the

purge boot on the purge station lid, where the vacuum removes residual fluid and cleans the

nozzle or needle tip.

Safety Interlock System

The Safety Interlock System (shown but not called out) works with the front door sensors

and the Light Beacon. Using the Safety Interlock key switch, you can place the system in

different access modes for servicing, programming, and production. Each mode allows or

limits access to the dispensing area.

Syringe

The syringe contains the fluid to be dispensed and comes in a variety of sizes, all

accommodated by the fluid pump. The fluid manufacturer packages the fluid in the syringe

according to the requirements of your application. The fluid is shipped with a Material

Safety and Data Sheet (MSDS), which provides handling and safety instructions.

Temperature Controller (option)

The system is equipped with either a HT-2000 or a 4-Channel Temperature Controller to

adjust the Needle Heater and the Heated Vacuum Tooling Plate from ambient to 100° C.

In addition, the 4-Channel Controller is capable of interfacing with the FMW. Other fluid

pumps may use the HT-1000 (or HT-2000) which controls temperatures from ambient to

100° C.

Vacuum On/Off Button for Heated Vacuum Tooling Plate

The Heated Vacuum Tooling Plate is controlled by an On/Off button located on the process

control cover. When the Vacuum button is pressed to ON, the button illuminates in yellow

and the vacuum is activated and remains illuminated until the button is pressed to OFF

which shuts down the vacuum.