User guide

Table Of Contents

AccuJet

t

Dispenser

24

E 1998 Nordson Corporation

All rights reserved

107 142B

Issued 4/98

Manual 12-34

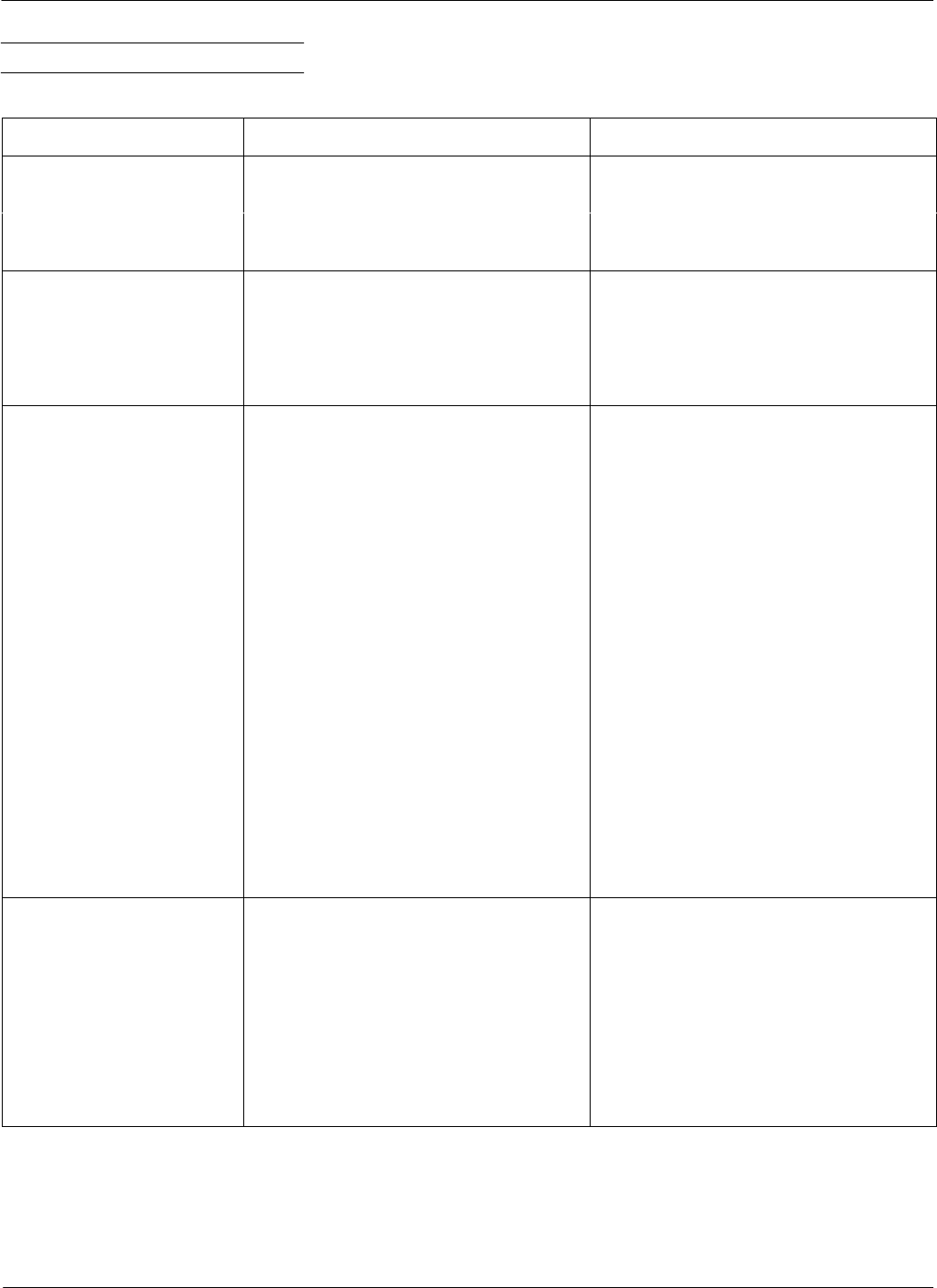

Problem Possible Cause Corrective Action

1. Dispenser does not

cycle

No signal to solenoid valve Check the solenoid connections

between the workcell and the dispenser.

Air pressure to solenoid valve is off or

insufficient

Make sure that air pressure is 5–6 bar

(70–90 psi).

2. Fluid leaks from weep

hole

Worn seal or needle Inspect the needle and seal for

excessive wear. Replace parts, if

necessary.

Lower seal missing Install a seal and secure it with the

retaining ring.

3. Adhesive dots do not

form

Plugged nozzle Clean nozzle with a compatible solvent

and Nordson cleaning wire. If nozzle

cannot be cleaned, replace it.

No adhesive in dispenser or air bubble

in the flow path

Use one of the following steps to purge

the dispenser:

S Manually actuate the solenoid valve.

S Send a signal to the solenoid valve to

allow adhesive flow through the

dispenser.

NOTE: You may have to remove the

nozzle prior to purging the dispenser.

Check the syringe connections and

pressure.

Dispenser not cycling Refer to Problem 1.

Failed dispenser component Disassemble the dispenser and inspect

the internal parts. Replace parts, if

necessary.

4. Dots are stringing or

stitching

Dirty nozzle Clean nozzle with a compatible solvent

and Nordson cleaning wire.

Loose nozzle Inspect the surface between the nozzle

and extension for adhesive and debris.

Clean, if necessary. Tighten the nozzle

to the specified torque.

Damaged nozzle Replace nozzle.

Incorrect temperature Refer to Table 2 for set-points.

6. Troubleshooting

(contd.)