User guide

Table Of Contents

AccuJet

t

Dispenser

13

E 1998 Nordson Corporation

All rights reserved

107 142B

Issued 4/98

Manual 12-34

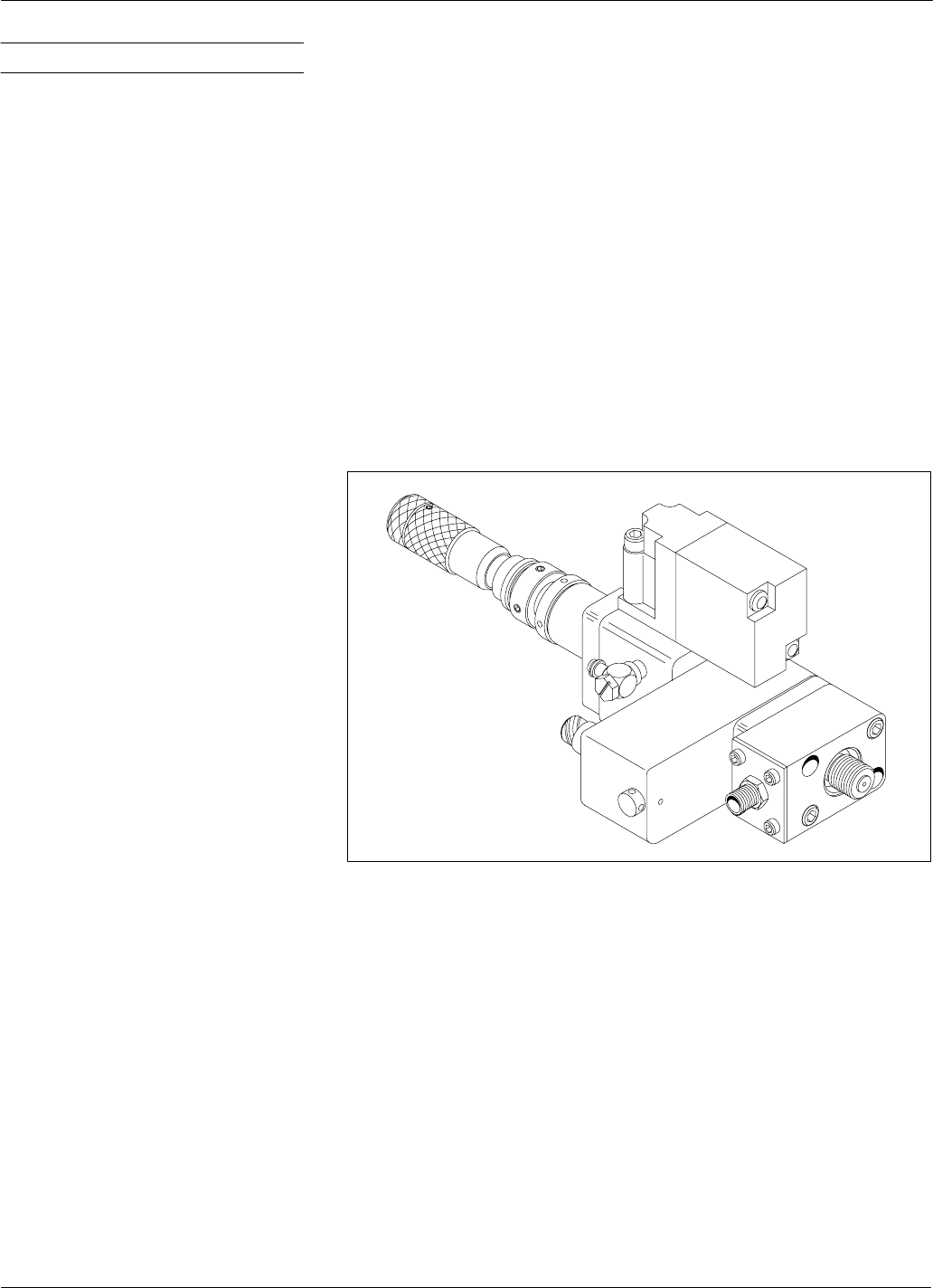

See Figure 1. The AccuJet dispenser applies adhesive dots on circuit

boards before surface-mounted electrical components are installed.

See Figure 2. A syringe (2) of adhesive connects to the dispenser.

Adhesive flows from the syringe at 0.35–2.1 bar (5–30 psi) and into the

fluid chamber. The heater (7) warms the adhesive to 40 to 55 _C

(104–131 _F) to reduce viscosity and improve flow characteristics. Air

pushes on the dispenser piston to retract the ball from the seat and

compress the spring. Adhesive fills the space left by the ball. When air

exhausts from the solenoid valve (8), the spring returns the ball to the

seat. The ball breaks the string of adhesive flowing through the

nozzle (6). The string of adhesive strikes the substrate and forms a dot.

Different sizes of dots can be formed by firing multiple dots on top of

each other.

The micro-adjustment assembly (3) controls piston and needle travel.

Turning the micro-adjustment

S clockwise, decreases piston travel and adhesive flow

S counterclockwise, increases piston travel and adhesive flow

1234011A

Fig. 1 AccuJet dispenser

2. Description