Install Instructions

51

IX: TROUBLESHOOTING (continued)

B. OIL PRIMARY CONTROL (OIL PRIMARY)

1. Burner (Oil Primary) will not come on.

a. No power to Oil Primary.

b. Oil Primary is in lockout or restricted mode.

Press reset button for one (1) second to exit

lockout. If control has recycled three times

within the same call for heat, it will enter into

restricted mode. To reset from restricted mode,

refer to Section V, Paragraph I, Step 2 for details.

c. CAD cell seeing light.

d. CAD assembly defective.

e. Control motor relay is stuck closed (see note

below).

2. Burner (control) will light, then shut down after a

short time, then restart after one (1) minute.

a. CAD cell is defective.

b. Air leaking into oil line causing ame out.

c. Defective nozzle causing ame to be erratic.

d. Excessive airow or draft causing ame to leave

burner head.

e. Excessive back pressure causing ame to be

erratic.

3. Control locks out after Trial For Ignition (TFI).

a. No oil to burner.

b. Shorted electrodes.

c. Nozzle clogged.

d. Airow too high.

e. Ignitor module defective.

f. CAD cell defective.

g. Oil valve stuck open or closed.

Note: The Safety Monitoring Circuit (SMC) is

designed to provide lockout in the event of a

stuck or welded motor relay.

Also refer to Model EZ-1/2/3 Oil Burner - Instruction

Manual (Form #MNEZ123) for additional information.

4. Carlin 70200 Oil Primary Control

a. Burner (control) will not come on.

i. No power to control.

ii. Control is in lockout. Press reset button for

one (1) second.

iii. CAD cell seeing light.

iv. CAD assembly defective.

v. Control motor relay is stuck closed (see note

below).

b. Burner (control) will light, then shut down after a

short time, then restart after one (1) minute.

i. CAD cell is defective.

ii. Air leaking into oil line causing ame out.

iii. Defective nozzle causing ame to be erratic.

iv. Excessive airow or draft causing ame to

be erratic.

v. Excessive back pressure causing ame to be

erratic.

c. Control locks out after Trial For Ignition (TFI).

i. No oil to burner.

ii. Shorted electrodes.

iii. Nozzle clogged.

iv. Airow too high.

v. Ignitor module defective.

vi. CAD cell defective.

vii. Oil valve stuck open or closed.

Note: The Safety Monitoring Circuit (SMC) is

designed to provide lockout in the event of a

stuck or welded motor relay.

NOTICE

If ame is not established within 15 seconds of

oil valve actuation (known as Trial For Ignition

[TFI]) lockout will occur. Lockout is indicated

by a red LED solid-on located on the oil primary

control.

Hard Lockout will occur if the Oil Primary

Control locks-out three (3) times during a call

for heat. This is indicated by red light reset

button solid-on.

C. INTELLIGENT OIL BOILER CONTROL

• Cold Start Boiler Control is used on Boilers without

Tankless Heaters.

• Warm Start Boiler Control is used on Boilers with

Tankless Heaters

1. When a problem occurs with the boiler operation,

the Boiler Control easily provides specic, valuable

information to help resolve the issue quickly. The

display on the Boiler Control should be the rst

place to check.

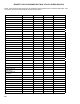

a. If an Error Code "" IS NOT displayed on

the Boiler Control: In this circumstance, Table

12 can be used to determine the problem and

possible causes.