User Guide

50

103876-08 - 1/19

CL Installation & Service Manual

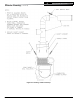

A. COMBUSTION

1. Nozzles — Although the nozzle is a relatively

inexpensive device, its function is critical to

the successful operation of the oil burner.

The selection of the nozzle supplied with the

CL boiler is the result of extensive testing

to obtain the best flame shape and efficient

combustion. Other brands of the same spray

angle and spray pattern may be used but may

not perform at the expected level of CO

2

and

smoke. Nozzles are delicate and should be

protected from dirt and abuse. Nozzles are

mass-produced and can vary from sample to

sample. For all of those reasons a spare nozzle

is a desirable item for a serviceman to have.

2. Fuel Leaks — Any fuel leak between the pump

and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in

the air tube, under the ignitor, and around the

air inlet. Any such leaks should be repaired as

they may cause erratic burning of the fuel and

in the extreme case may become a fire hazard.

3. Suction Line Leaks — Any such leaks should

be repaired, as they may cause erratic burning

of the fuel and in extreme cases may become

a fire hazard. Whatever it takes, The Oil Must

Be Free of Air. This can be a tough problem,

but it must be resolved. Try bleeding the pump

through a clear tube. There must be no froth

visible. There are various test kits available

to enable you to look at the oil through clear

tubing adapted to the supply line at the pump

fitting. Air eliminators are on the market that

have potential. Also, electronic sight glasses

are being used with good success. At times,

new tubing must be run to the tank or new

fittings put on. Just make sure you get the air

out before you leave.

Any air leaks in the fuel line will cause an

unstable flame and may cause delayed ignition

noises. Use only flare fittings in the fuel lines.

4. Gasket Leaks — If 11.5 to 12.5% CO

2

with a #1

smoke cannot be obtained in the breeching,

look for air leaks around the burner mounting

gasket, observation door, and canopy gasket.

Such air leaks will cause a lower CO

2

reading

in the breeching. The smaller the firing rate

the greater effect an air leak can have on CO

2

readings.

5. Dirt — A fuel filter is a good investment.

Accidental accumulation of dirt in the fuel

system can clog the nozzle or nozzle strainer

and produce a poor spray pattern from the

nozzle. The smaller the firing rate, the smaller

the slots become in the nozzle and the more

prone to plugging it becomes with the same

amount of dirt.

6. Water — Water in the fuel in large amounts

will stall the fuel pump. Water in the fuel in

smaller amounts will cause excessive wear on

the pump, but more importantly water doesn’t

burn. It chills the flame and causes smoke and

unburned fuel to pass out of the combustion

chamber and clog the flueways of the boiler.

7. Cold Oil — If the oil temperature approaching

the fuel pump is 40°F or lower, poor

combustion or delayed ignition may result.

Cold oil is harder to atomize at the nozzle.

Thus, the spray droplets get larger and the

flame shape gets longer. An outside fuel

tank that is above grade or has fuel lines in a

shallow bury is a good candidate for cold oil.

The best solution is to locate the tank near the

boiler in the basement utility room or bury the

tank and lines deep enough to keep the oil

above 40°F. Check environmental issues with

local authorities having jurisdiction.

8. Fame Shape — Looking into the combustion

chamber through the observation port, the

flame should appear straight with no sparklers

rolling up toward the crown of the chamber.

If the flame drags to the right or left, sends

sparklers upward or makes wet spots on the

target wall, the nozzle should be replaced. If

the condition persists look for fuel leaks, air

leaks, water or dirt in the fuel as described

above.

9. High Altitude Installations — Air openings

must be increased at higher altitudes. Use

instruments and set for 11.5 to 12.5% CO

2

.

10. Start-up Noise — Late ignition is the cause

of start-up noises. If it occurs recheck for

electrode settings, flame shape, air or water in

the fuel lines.

11. Shut Down Noise — If the flame runs out of

air before it runs out of fuel, an after burn with

noise may occur. That may be the result of a

faulty cut-off valve in the fuel pump, or it may

be air trapped in the nozzle line. It may take

several firing cycles for that air to be fully

vented through the nozzle. Water in the fuel or

poor flame shape can also cause shut down

noises.

NOTICE

CHECK TEST PROCEDURE. A very good test for

isolating fuel side problems is to disconnect the

fuel system and with a 24" length of tubing, fire

out of an auxiliary five gallon pail of clean, fresh,

warm #2 oil from another source. If the burner runs

successfully when drawing out of the auxiliary

pail then the problem is isolated to the fuel or fuel

lines being used on the jobsite.

9 Troubleshooting