DAQ 6023E/6024E/6025E Multifunction I/O Devices User Manual

Table Of Contents

- 6023E/6024E/6025E User Manual

- Support

- Important Information

- Contents

- About This Manual

- Chapter 1 Introduction

- Chapter 2 Installation and Configuration

- Chapter 3 Hardware Overview

- Chapter 4 Signal Connections

- I/O Connector

- Analog Input Signal Overview

- Analog Input Signal Connections

- Analog Output Signal Connections

- Digital I/O Signal Connections

- Programmable Peripheral Interface (PPI)

- Power Connections

- Timing Connections

- Field Wiring Considerations

- Chapter 5 Calibration

- Appendix A Specifications

- Appendix B Custom Cabling and Optional Connectors

- Appendix C Common Questions

- Appendix D Technical Support Resources

- Glossary

- Index

- Figures

- Figure 1-1. The Relationship Between the Programming Environment, NI-DAQ, and Your Hardware

- Figure 3-1. PCI-6023E, PCI-6024E, PCI-6025E, and PXI-6025E Block Diagram

- Figure 3-2. DAQCard-6024E Block Diagram

- Figure 3-3. Dithering

- Figure 3-4. CONVERT* Signal Routing

- Figure 3-5. PCI RTSI Bus Signal Connection

- Figure 3-6. PXI RTSI Bus Signal Connection

- Figure 4-1. I/O Connector Pin Assignment for the 6023E/6024E

- Figure 4-2. I/O Connector Pin Assignment for the 6025E

- Figure 4-3. Programmable Gain Instrumentation Amplifier (PGIA)

- Figure 4-4. Summary of Analog Input Connections

- Figure 4-5. Differential Input Connections for Ground Referenced Signals

- Figure 4-6. Differential Input Connections for Nonreferenced Signals

- Figure 4-7. Single Ended Input Connections for Nonreferenced or Floating Signals

- Figure 4-8. Single Ended Input Connections for Ground Referenced Signals

- Figure 4-9. Analog Output Connections

- Figure 4-10. Digital I/O Connections

- Figure 4-11. Digital I/O Connections Block Diagram

- Figure 4-12. DIO Channel Configured for High DIO Power-up State with External Load

- Figure 4-13. Timing Specifications for Mode 1 Input Transfer

- Figure 4-14. Timing Specifications for Mode 1 Output Transfer

- Figure 4-15. Timing Specifications for Mode 2 Bidirectional Transfer

- Figure 4-16. Timing I/O Connections

- Figure 4-17. Typical Posttriggered Acquisition

- Figure 4-18. Typical Pretriggered Acquisition

- Figure 4-19. SCANCLK Signal Timing

- Figure 4-20. EXTSTROBE* Signal Timing

- Figure 4-21. TRIG1 Input Signal Timing

- Figure 4-22. TRIG1 Output Signal Timing

- Figure 4-23. TRIG2 Input Signal Timing

- Figure 4-24. TRIG2 Output Signal Timing

- Figure 4-25. STARTSCAN Input Signal Timing

- Figure 4-26. STARTSCAN Output Signal Timing

- Figure 4-27. CONVERT* Input Signal Timing

- Figure 4-28. CONVERT* Output Signal Timing

- Figure 4-29. SISOURCE Signal Timing

- Figure 4-30. WFTRIG Input Signal Timing

- Figure 4-31. WFTRIG Output Signal Timing

- Figure 4-32. UPDATE* Input Signal Timing

- Figure 4-33. UPDATE* Output Signal Timing

- Figure 4-34. UISOURCE Signal Timing

- Figure 4-35. GPCTR0_SOURCE Signal Timing

- Figure 4-36. GPCTR0_GATE Signal Timing in Edge Detection Mode

- Figure 4-37. GPCTR0_OUT Signal Timing

- Figure 4-38. GPCTR1_SOURCE Signal Timing

- Figure 4-39. GPCTR1_GATE Signal Timing in Edge Detection Mode

- Figure 4-40. GPCTR1_OUT Signal Timing

- Figure 4-41. GPCTR Timing Summary

- Figure B-1. 68 Pin E Series Connector Pin Assignments

- Figure B-2. 68 Pin Extended Digital Input Connector Pin Assignments

- Figure B-3. 50 Pin E Series Connector Pin Assignments

- Figure B-4. 50-Pin Extended Digital Input Connector Pin Assignments

- Tables

- Table 3-1. Available Input Configurations

- Table 3-2. Measurement Precision

- Table 3-3. Pins Used by PXI E Series Device

- Table 4-1. I/O Connector Details

- Table 4-2. I/O Connector Signal Descriptions

- Table 4-3. I/O Signal Summary

- Table 4-4. Port C Signal Assignments

- Table 4-5. Signal Names Used in Timing Diagrams

Chapter 4 Signal Connections

6023E/6024E/6025E User Manual 4-24 ni.com

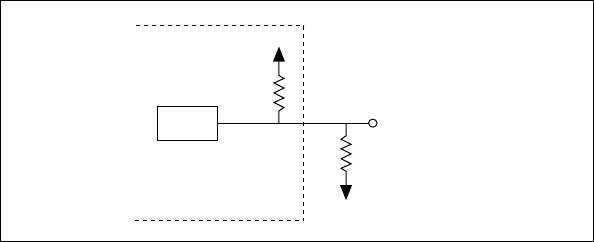

Power-up State

♦ 6025E only

The 6025E contains bias resistors that control the state of the digital I/O

lines PA<0..7>,PB<0..7>,PC<0..7> at power up. Each digital I/O line is

configured as an input, pulled high by a 100 kΩ bias resistor.

You can change individual lines from pulled up to pulled down by adding

your own external resistors. This section describes the procedure.

Changing DIO Power-up State to Pulled Low

Each DIO line is pulled to V

cc

(approximately +5 VDC) with a 100 kΩ

resistor. To pull a specific line low, connect between that line and ground

a pull-down resistor (R

L

) whose value gives you a maximum of 0.4 VDC.

The DIO lines provide a maximum of 2.5 mA at 3.7 V in the high state.

Using the largest possible resistor ensures that you do not use more current

than necessary to perform the pull-down task.

However, make sure the value of the resistor is not so large that leakage

current from the DIO line along with the current from the 100 kΩ pull-up

resistor drives the voltage at the resistor above a TTL-low level of 0.4 VDC.

Figure 4-12 shows the DIO configuration for high DIO power-up state.

Figure 4-12. DIO Channel Configured for High DIO Power-up State with External Load

Example

A given DIO line is pulled high at power up. To pull it low on power up with

an external resistor, follow these steps:

1. Install a load (R

L

). Remember that the smaller the resistance, the

greater the current consumption and the lower the voltage.

Device

Digital I/O Line

82C55

100 k

GND

R

L

+5 V