Technical Manual

34 All technical manuals are available in PDF format at tech.napcosecurity.com Napco iSecure Security System

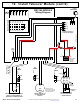

12. Install Takeover Module (cont'd)

BATT+ ... Optional connection to the existing Hub battery +

terminal (or + terminal of the power supply) for pow-

er supervision. Place shunt across JP3 to enable

supervision.

PNL+ ...... External +12VDC power input used to power the

FIRE terminal (described above). Remove jump-

er JP13 when FIRE output is powered by an exter-

nal power source (for example, wired to the DC+

output of an external power supply). Install JP13 to

power the FIRE terminal from internal DC power.

IMPORTANT: NEVER install wire to terminal

PNL+ when JP13 is installed.

JUMPER DESCRIPTIONS

Jumper Block P2

These "Learn jumpers" are in the P2 jumper block with posi-

tions numbered, from left to right, as 1 to 6:

P2 Position 1 - Shunt position 1 to DEFAULT all board flash

memory to the factory default settings (enters RF LEARN

mode). Shunt position 1 before power up; after the ISEC-

WL-MODULE is powered, remove jumper from posi-

tion 1 and the LED marked LED1 will flash, indicating the

unit is waiting to be learned into the Go-Anywhere Hub.

When this learn process completes, LED1 stops flashing

and remains lit.

P2 Position 2 - Shunt position 2 to DISABLE AC monitoring

of terminals ACL and ACN. If you wish to disable monitor-

ing of the AC transformer that powers the DC power sup-

ply and you also wish to enable AC FAIL reporting, shunt

this jumper 2. When P2 is not shunted, the removal of AC

will cause the system to annunciate.

P2 Position 3 - Shunt position 3 to DISABLE BATTERY

monitoring on the terminal BATT+.

P2 Position 4 - Reserved for future use.

P2 Position 5 - Reserved for future use.

P2 Position 6 - Shunt position 6 to start an END OF LINE

RESISTOR LEARN process for zone terminals Z1

through Z8 whereby the value of each normal zone condi-

tion is learned by the system. Within 3 seconds of shunt-

ing position 6, LED3 (at the top of the PC board) will blink

to indicate the learn process is active. This learning pro-

cess requires that the zone be wired to a sensor and

ZONE # jumper (JP5 to JP12; see below) be removed

for a short time and re-installed. Each normal zone condi-

tion is learned by the system. If the zone is open, the

zone condition will not be learned. When the zone learn-

ing process ends, remove jumper from position 6; in 3

seconds, LED3 will turn off to indicate the learning pro-

cess has ended. Note: The factory default value of the

zone terminating resistor is 2.2KΩ, and therefore does

NOT require this END OF LINE RESISTOR LEARN pro-

cess!

Zone Monitoring Jumpers (JP5 to JP12)

To enable zone monitoring for a zone, place a jumper one of

the 8 jumper blocks labeled JP5 (for ZONE 1) through JP12

(for ZONE 8). Each zone 1 - 8 is assigned to terminals Z1

through Z8, respectively.

Notice each jumper block labeled JP5 through JP12 contains

vertical 4 pins:

FIRE (top two pins): Selected zone reports as a Fire

transmitter (for example, a model ISEC-SMOKE detec-

tor).

CO (middle two pins): Selected zone reports as a

carbon monoxide (model ISEC-CARBON MON) trans-

mitter.

BURG (lower two pins): Selected zone reports as a

Burglary window / door transmitter (model ISEC-DW-

XMITTER) with one point (i.e. reports the zone

change from "normal" to "open").

SPECIFICATIONS

Electrical Ratings

Input Power: 12.5 - 7.5VDC, 60mA.

Zone Loop current: 4.7mA nominal, 5.5mA when shorted.

Maximum Zone Loop Resistance: 300 ohms.

2.2K End of line resistor (part number EOL2.2K required

in Fire applications).

Output Power:

PGM Output (Active low): 5mA, 12V. Connect only to

power-limited circuits less than 14VDC. Use only in

Burglary applications.

Ground Faults Detected: 1.25KΩ to ground or less.

BATTERY MONITORING

When monitoring the battery is required, install the shunt

across P2 Position 2.

Battery Wiring:

1. Disconnect the battery of the Hub to be taken over and

unplug its AC transformer.

2. Cut the control panel's red battery flying lead approxi-

mately 3 inches from the battery terminal.

3. Strip both sides of the cut flying lead to expose wire.

4. Inside the panel housing, using a suitable wire connector,

crimp both sides of the stripped flying battery lead and

one side of the supplied EOLR2.2K.

5. Using a suitable connector, crimp the remaining side of

the EOLR2.2k to the wire that extends outside the panel

housing to the ISEC-WL-MODULE "BATT+" terminal.

6. Ensure the wires connected to the battery are separated

by at least 1/4 inch from any non-power limited wire in-

side the panel housing.

Enable AC Fail Monitoring:

Install shunt across header P2 Position 1.

For the Hub to be taken over, connect the AC terminal to

the ISEC-WL-MODULE "ACL" terminal.

continued