Specifications

MODULAR LIGHT TOWER — PARTS & OPERATION MANUAL — REV. #3 (06/26/06) — PAGE 25

Brakes

If your trailer has a braking system, the brakes should be

inspected the first 200 miles of operation. This will allow the

brake shoes and drums to seat properly. After the first 200

mile interval, inspect the brakes every 3,000 miles. If driv-

ing over rough terrain inspect brakes more frequently.

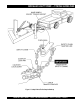

Electric Brakes

Electrically actuated brakes (Figure 8) are similar to hydrau-

lic brakes. The basic difference is that hydraulic brakes are

actuated by

pressure

, while electric brakes are actuated by

an

electromagnet.

Listed below are some of the advantages that electric brakes

have over hydraulic brakes:

■

Brake system can be manually adjusted to provide the

corrected braking capability for varying road and load

conditions.

■

Brake system can be modulated to provide more or less

braking force, thus easing the break load on the towing

vehicle.

■

Brake system has very little lag time between the time the to

vehicle's brakes are actuated and the trailer's brakes are

actuated.

■

Brake system can provide an independent emergency brake

system.

Remember in order to properly synchronize the tow vehicle's

braking to that of the trailer's braking, can only be accom-

plished by road testing. Brake lockup, grabbiness or harsh-

ness is due to lack of synchronization between the tow ve-

hicle and the trailer being towed or under-adjusted brakes.

Before any brake synchronizations adjustments can be

made, the trailer brakes should be burnished-in by applying

the brakes 20-30 times with approximately a 20 mph de-

crease in speed, e.g. 40 mph to 20 mph. Allow ample time

for brakes to cool between application. This allows the brake

shoes to slightly be seated into the brake drum surface.

Figure 8 display's the major electric brake components that

will require inspection and maintenance. Please inspect

these components as required. Reference Table 7 for elec-

tric brake troubleshooting guidelines.

Electric Brake Adjustment

1. Place the trailer on jack stands. Make sure that the jack stands

are placed on secure level ground.

2. Check the wheel and drum for free rotation.

3. Remove the adjusting hole cover from the adjusting slot at

the bottom brake backing plate.

4. With a screwdriver or standard adjusting tool, rotate the star

wheel of the adjuster assembly to expand the brake shows.

5. Adjust the brake shoes outward until the pressure of the

lining against the wheel drum makes the wheel difficult to

turn.

6. Rotate the star wheel in the opposite direction until the wheel

rotates freely with slight lining drag.

7. Replace the adjusting hole cover and lower the trailer to the

ground.

8. Repeat steps 1 through 6 on the remaining brakes.

MODULAR LIGHT TOWER — TRAILER SAFETY GUIDELINES