User Manual

Table Of Contents

- Technical Support

- Preface

- Introduction

- Overview Reference

- Series 647 Hydraulic Wedge Grips Component Identification

- Series 647 Hydraulic Wedge Grips Functional Description

- About Gripping Specimens

- About Wedges

- About Spiral Washers

- About Couplings

- About All Temperature Grips

- About Environmental Chambers

- Hydraulic Fluid Recommendations

- Cooling Water Specifications

- Series 647 Wedge Grip Temperature Ranges

- Series 647 Hydraulic Wedge Grip Force and Torque Capacities

- Safety

- General Safety Practices: Grips and Fixtures

- Read all manuals

- Avoid Pinch and Crush Points

- Locate and read hazard placards/labels

- Know facility safe procedures

- Know controls

- Know Specimen Properties

- Have first aid available

- Be aware of component movement with hydraulics off

- Keep bystanders safely away

- Wear proper clothing

- Remove flammable fluids

- Check bolt ratings and torques

- Lift Equipment Safely

- Practice good housekeeping

- Do not exceed the Maximum Supply Pressure

- Do not disable safety devices

- Provide adequate lighting

- Provide means to access out-of-reach components

- Wear appropriate personal protection

- Handle chemicals safely

- Know system interlocks

- Know system limits

- Do not disturb sensors

- Ensure secure cables

- Stay alert

- Contain small leaks

- Stay clear of moving equipment/avoid crush points

- Know the causes of unexpected actuator motions

- General Precautions for Environmental Components

- Hazard Placard Placement

- General Safety Practices: Grips and Fixtures

- Installation

- Operation

- Maintenance

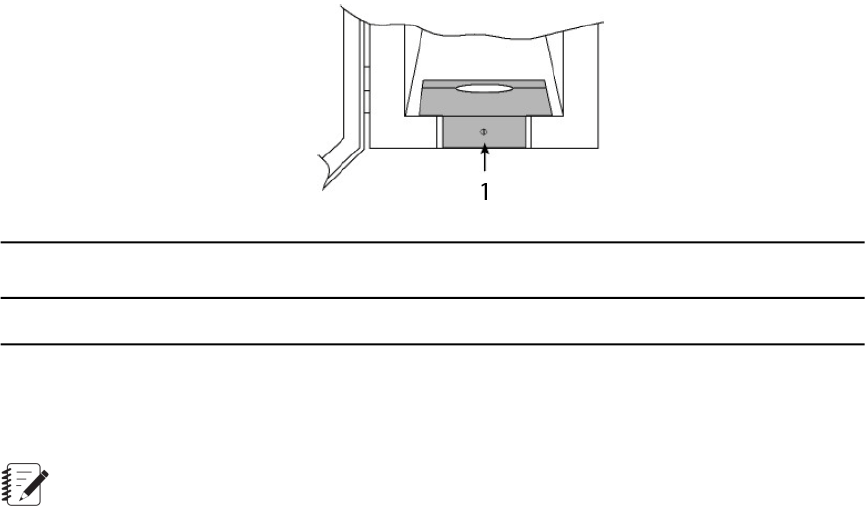

• If the environmental chamber has upper and lower U-plugs, install the grips first, then install the

environmental chamber. Simply remove the U-plugs from the chamber, move the environmental chamber

around the grips, and reinstall the U-plugs (see Install Environmental Chambers with U-Plugs on page

51).

DescriptionItem

Lower U-plug1

• If the environmental chamber has no U-plugs, the environmental chamber must installed first. Then the

grips must be partially disassembled and reassembled after the environmental chamber is installed (see

Install Environmental Chambers Without U-Plugs on page 55).

Note:

See the environmental chamber product manual for additional information.

Required equipment

Equipment and materials required to install the all-temperature grips include:

• The appropriate attachment kit includes the components to install the grips

• Appropriately sized device to lift the heavier grips

• Appropriately sized double swivel eyebolts and wood blocks or plywood sheet for lifting the heavier grips

• Lubricant

• Hydraulic plumbing capable of withstanding the temperature extremes

• An environmental chamber

• A heating/cooling kit

• A tool kit is provided with each set of grips. It contains a set of spare extension springs for securing the

wedges in the grip, a utility hook, the tools required to disassemble the grip, and eye bolts and a swivel

eye for installing and removing the grips.

Install Environmental Chambers with U-Plugs

The following procedure assumes the actuator is mounted in the base of the load unit and that the force

transducer is mounted to the crosshead. If you have a load unit with the actuator mounted to the crosshead,

make the appropriate changes to the following procedure.

For an assembly reference, see Axial-Torsional Grip Installation Components on page 45.

Series 647 Hydraulic Wedge Grips Reference Manual 51

Installation