User Manual

310-2200 EZT

®

3

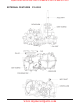

HYDRAULIC SCHEMATIC

Figure 2 provides an illustration of the hydraulic

oil circuit. The oil supply for the hydraulic sys-

tem of the 310-2200 EZT

®

is also utilized for lu-

bricating the components of the final drive as-

sembly.

The input shaft and pump cylinder block are

turned in one direction only by the engine/drive

belt/pulley combination. Output of the oil flow is

controlled by the direction and amount that the

variable swashplate is angled. As the pump pis-

tons compress they force the oil to flow through

one of two passageways (forward or reverse)

in the center section to the motor cylinder block

and motor shaft. Since the motor has a fixed

displacement angle it is forced to turn with the

flow of oil. As the angle of the pump swashplate

is increased the amount of oil being pumped will

increase and cause a higher speed output of the

motor. Reversing the angle of the pump

swashplate will reverse the direction of oil flow.

During the operation of the transaxle, fluid is

“lost” from the hydraulic loop through leak paths

designed into the product for lubrication purposes

(around pistons, under the rotating cylinder

blocks, etc.). This “lost” fluid returns to the

transaxle housing, then is pulled back into one

of the check valves depending upon the direc-

tion of vehicle operation. All of this oil must pass

through an internal filter.

The motor cylinder block mounts onto a splined

motor shaft which drives the gear train.

The bypass feature in the 310-2200 has a me-

chanical lever which lifts the motor block off of

the center section running surface. This allows

oil flow from the cylinder blocks to be discharged.

Figure 2. Hydraulic Flow Illustration

310-2200 EZT

®

HYDRAULIC FLOW SCHEMATIC

www.mymowerparts.com

Hydro Gear Parts or New Units Call 606-678-9623 or 606-561-4983