Installation User guide

2 INSTALLATION INSTRUCTIONS

M S D • W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

CHOOSING AN ADVANCE CURVE

The function of the advance curve is to match the ignition timing to the burning rate of the fuel and

speed (rpm) of the engine. Any factor that changes the burning rate of the fuel or the engine speed

can cause a need for an ignition timing change. Figure 1 shows some of the factors that will affect

engine timing.

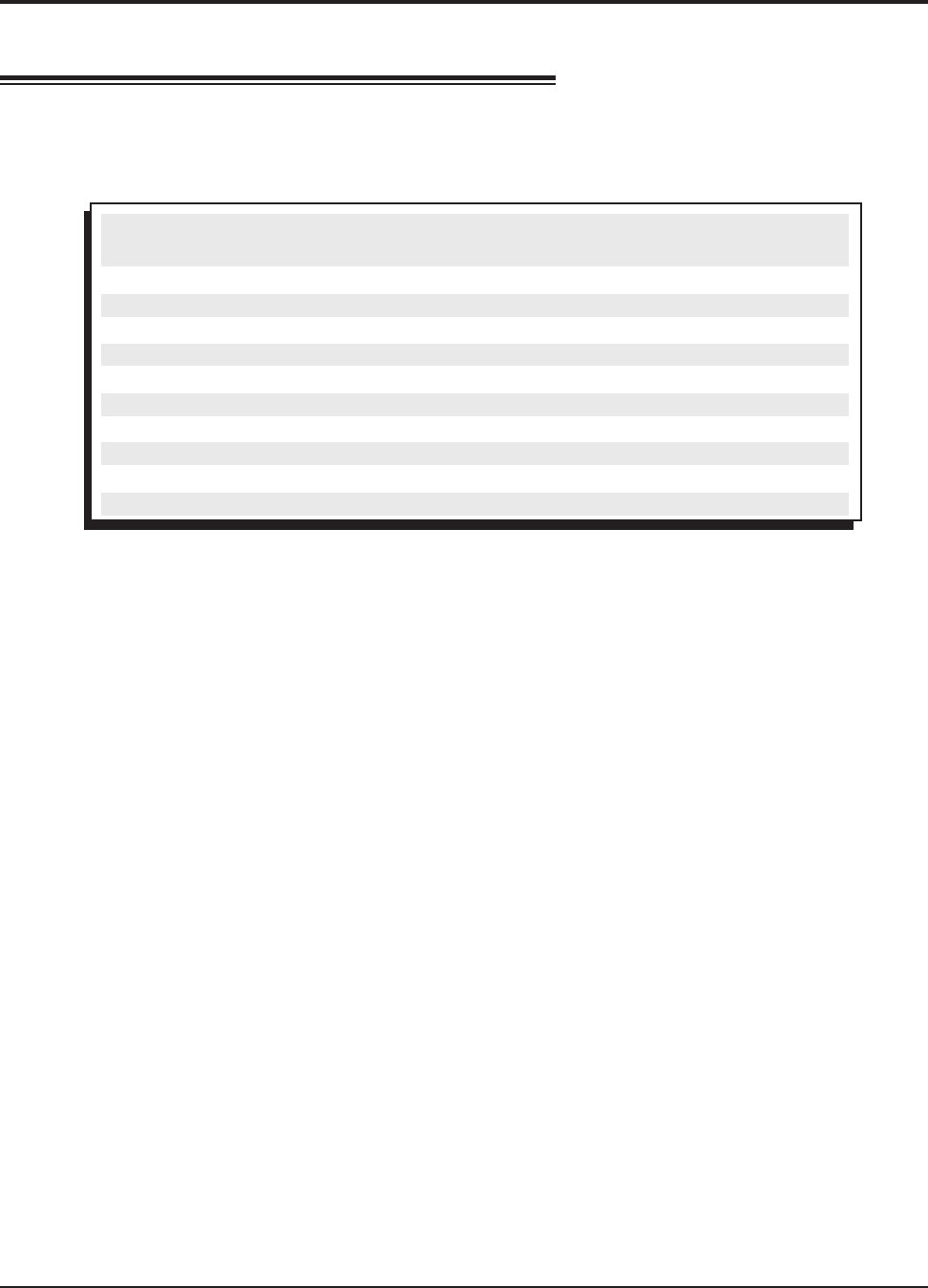

FACTOR Advance Timing Retard Timing

For For

Cylinder Pressure Low High

Vacuum High Low

Energy of Ignition Low High

Fuel Octane High Low

Mixture (Air/Fuel) Rich Lean

Temperature Cool Hot

Combustion Chamber Shape Open Compact

Spark Plug Location Offset Center

Combustion Turbulence Low High

Load Light Heavy

Figure 1 Ignition Timing Factors.

As you can see from the chart, most factors will change throughout the range of the engine operation.

The timing mechanism of the distributor must make timing changes based on these factors.

Example: An engine has 11:1 compression, a high energy ignition and turns 5,500 rpm. With the

specifications given, you will have to retard the timing for the high compression, low rpm and high

energy ignition. By comparing the engine’s specifications against the chart, a usable timing guideline

can be found. Engines with a combination of items from both columns will require a timing that is

set in the mid range.

Obviously a full technical explanation of correct ignition timing would be very complicated. The best

way to arrive at a suitable ignition curve for your engine is to use the Ignition Timing Factors Chart

as a guide and compare it to the Advance Graphs in Figure 4 until a suitable curve is found. When

selecting your advance curve, use detonation (engine ping) as an indicator of too much advance,

and a decrease in power as an indicator of too little advance.

TIPS ON SELECTING AN ADVANCE CURVE

• Use as much initial advance as possible without encountering excessive starter load.

• Start the centrifugal advance just above the idle rpm.

• The starting point of the centrifugal advance curve is controlled by the in stal led length and

tension of the spring.

• How quickly the centrifugal advance (slope) comes in is controlled by the spring stiffness. The

stiffer the spring, the slower the advance curve.

• The amoun t of advance is controlled by the advance bushing. The bigger the bushing, the

smaller the amount of advance.