Installation Guide

36

I&O manual

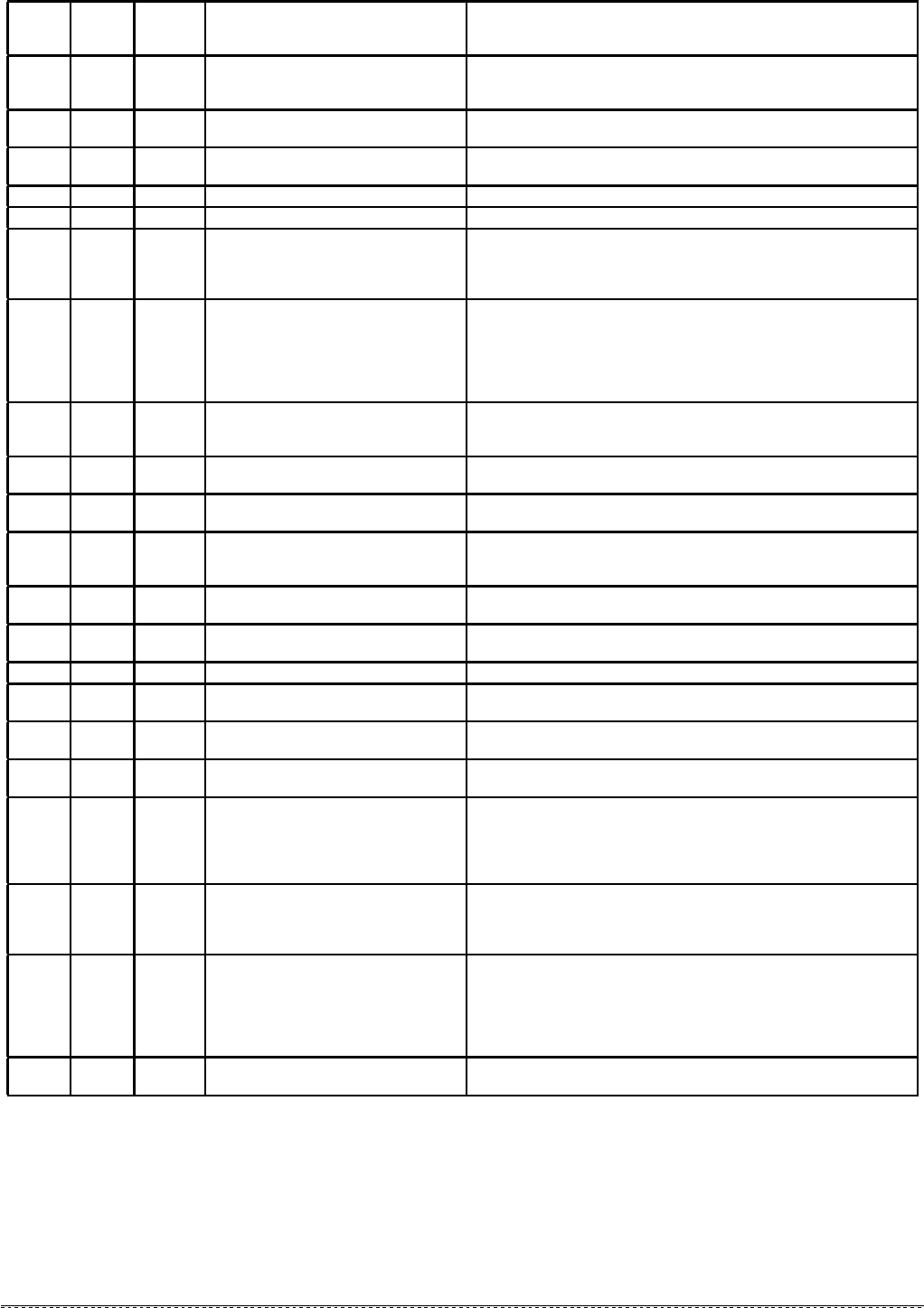

Table 16- Troubleshooting Chart

1 Integrated control module will automatically attempt to reset from lockout after one hour.

2 LED Flash code will cease if power to the control module is interrupted through the disconnect or door switch.

Green

LED

Flash

Amber

LED

Flash

Red LED

Flash

Error/Condition Comments/Troubleshooting

1 Flame sensed when no flame should

be present

Verify the gas valve is operating and shutting down properly. Flame

in burner assemble should extinguish promptly at the end of the

cycle. Check orifices and gas pressure.

2 Pressure switch stuck closed/ inducer

error

Pressure switch stuck closed. Check switch function, verify inducer

is turning off.

3 1st-stage pressure switch stuck open/

inducer error

Check pressure switch function and tubing. Verify inducer is turning

on the pulling sufficient vacuum to engage switch.

4 Open limit switch Verify continuity through rollout switch circuit.

5 Open rollout/open fuse detect Verify continuity through rollout switch circuit, check fuse.

6 1st-stage pressure switch cycle

lockout one call for heat from the thermostat the control will lockout. Check

if the first stage pressure switch cycles 5 times (open, closed) during

pressure switch for fluttering, inconsistent closure or poor vacuum

pressure.

7 External lockout (retries) Failure to sense flame is often caused by carbon deposits on the

flame sensor, a disconnected or shorted flame sensor lead or a

poorly grounded furnace. Carbon deposits can be cleaned with

emery cloth. Verify sensor is not contacting the burner and is located

in a good position to sense flame. Check sensor lead for shorting

and verify furnace is grounded properly.

8 External lockout (ignition recycles

exceeded where flame is established

and then lost)

Check items for exceeded retries listed above and verify valve is not

dropping out allowing flame to be established and then lost.

9 Grounding or Reversed polarity Verify the control and furnace are properly grounded. Check and

reverse polarity (primary) if incorrect.

10 Module gas valve contacts energized

with no call for heat

Verify valve is not receiving voltage from a short. If a valve wiring is

correct and condition persists, replace module.

11 Limit switch open – possible blower

failure overheating limit

Possible blower failure, restricted air flow through appliance or

duct work. Verify continuity through limit switch circuit and correct

overheating cause.

12 Module Ignitor contact failure Fault code indicates the module ignitor contacts are not functioning

properly. Replace module.

Solid Module - internal fault condition Module contacts for gas valve not operating or processor fault.

Reset control. if condition persists replace module.

Rapid Twinning error Check wire connections. If condition persists, replace module.

3 double 2nd-stage Pressure Switch Stuck

Open/Inducer Error

Check pressure switch function and tubing. Verify inducer is turning

on and pulling sufficient vacuum to engage switch.

1 Normal Operation with call for first

stage heat

Normal operation - first stage

2 Normal Operation with call for second

stage heat

Normal operation - first stage

3 W2 present with no W1 Second stage call for heat on thermostat circuit with no call for first

stage. Verify dip switches are set for two stage thermostat and check

thermostat first stage circuit. Configured for a multi-stage thermostat

the Module will not initiate heating unless first stage call from

thermostat is received.

4 Y present with no G call Module will allow cooling to operate with only a "Y signal from

the thermostat but will also trigger this code. Verify thermostat is

energizing both "Y" and "G" on call for cool. Check "G" terminal

connections.

Rapid Low flame sense current Low flame sense current is often caused by carbon deposits on

the flame sensor, a poorly grounded furnace or a mis-aligned

flame sense probe. Carbon deposits can be cleaned with emery

cloth. Check for improve furnace and module ground. Verify sensor

is located in or very near flame as specified by the appliance

manufacturer.

1 Standby or Call for Cool Normal operation. Waiting for call from thermostat or receiving

thermostat call for cool.