Installation Guide

32

I&O manual

10.4 Sequence of Operation

3. FAN Mode

2. Cooling Mode

If the thermostat fan switch is moved to the ON position, the

circulator fan (low heat speed) and the electronic air cleaner

(optional) are energized. When the fan switch is returned to

the AUTO position, the circulator and electronic air cleaner are

de-energized.

NOTE: Furnace control must be grounded for proper operation or

control will lock out. Control is grounded through green wire routed to

gas valve and manifold bracket screw. follow the sequence of

operation through the different modes.

Read and follow the wiring diagram very carefully.

The blower door must be installed for power to be conducted through

the blower door interlock switch to the furnace control CPU,

transformer , inducer motor, blower motor , hot--surface igniter , and

gas valve .

1. Heating mode

In a typical system, a call for first stage heat is initiated by closing the

W1 thermostat contacts. The inducer blower is energized at high

speed and the control waits for the low pressure switch contacts to

close. The humidifier (optional) is also energized at this time. Once

the low pressure switch contacts close, a 15-second pre-purge is

initiated. Then the inducer changes to low speed and the 120V ignitor

is powered. At the end of the ignitor warm-up time, the first stage of

the two-stage manifold gas valve is energized (low fire). Flame must

be detected within 4 seconds. If flame is detected, the 45-second

HEAT delay-to-fan-on period begins. After the delay-to-fan-on period

ends, the control will energize the circulator fan at low heat speed.

The electronic air cleaner (optional) will also energize at this time.

For a two-stage thermostat, a call for second stage heat (W1 and W2)

after a call for first stage heat will energize the inducer at high speed

and the circulator at high heat speed. The second stage pressure

switch contacts will close and energize the second stage gas valve

(high fire). For a single-stage thermostat, when a call for heat occurs

(W1), a 10, 20 minute or auto mode heat staging timer will be

activated (timing is selectable with option switches S1-1 and S1-2

positions). Following this delay, the second stage heat is energized as

above. The AUTO model algorithm is a method of energizing the

second stage gas valve based on the recent average of the heating

duty cycle. During a typical heating day, the low to high stage delay

is determined by using the average calculated duty cycle from the

table below. Once the specified delay time has expired the second

stage valve will be energized. See the table below for the different

duty cycles.

When the second stage of the thermostat is satisfied, the inducer

motor is reduced to low speed and the second stage gas valve is

de-energized.On the control, the circulator will remain at high heat

speed for 30 seconds following the opening of the second stage gas

valve and then is reduced to low heat speed. When the first stage of

the thermostat is satisfied, the first stage gas valve is de-energized

and the HEAT delay-to-fan-off begins timing. The inducer will

postpurge for an additional 15 seconds, then the inducer and

humidifier will turn off. Upon completion of the HEAT delay-to-fan-off

period, the circulator is turned off. The electronic air cleaner on the

control is also de-energized at this time.

If flame is not detected during the trial-for-ignition period or if the flame

is detected/sensed and then lost before completion of 10 seconds of

establishment, the gas valve is de-energized, the ignitor is turned off,

and the control goes into the “retry” sequence. The “retry” sequence

provides a 60-second wait with the inducer interpurge following an

unsuccessful ignition attempt (flame not detected). After this wait, the

ignition attempt is restarted. Two retries will be attempted before the

control goes into system lockout. If flame is established for more than

10 seconds after ignition, the controller will clear the ignition attempt

(or retry) counter. If flame is lost after 10 seconds, the control will

restart the ignition sequence.

A momentary loss of gas supply, flame blowout, or a shorted or

open condition in the flame probe circuit will be sensed within 2.0

seconds. The gas valve will de-energize and the control will

restart the ignition sequence. Recycles will begin and the burner

will operate normally if the gas supply returns, or the fault

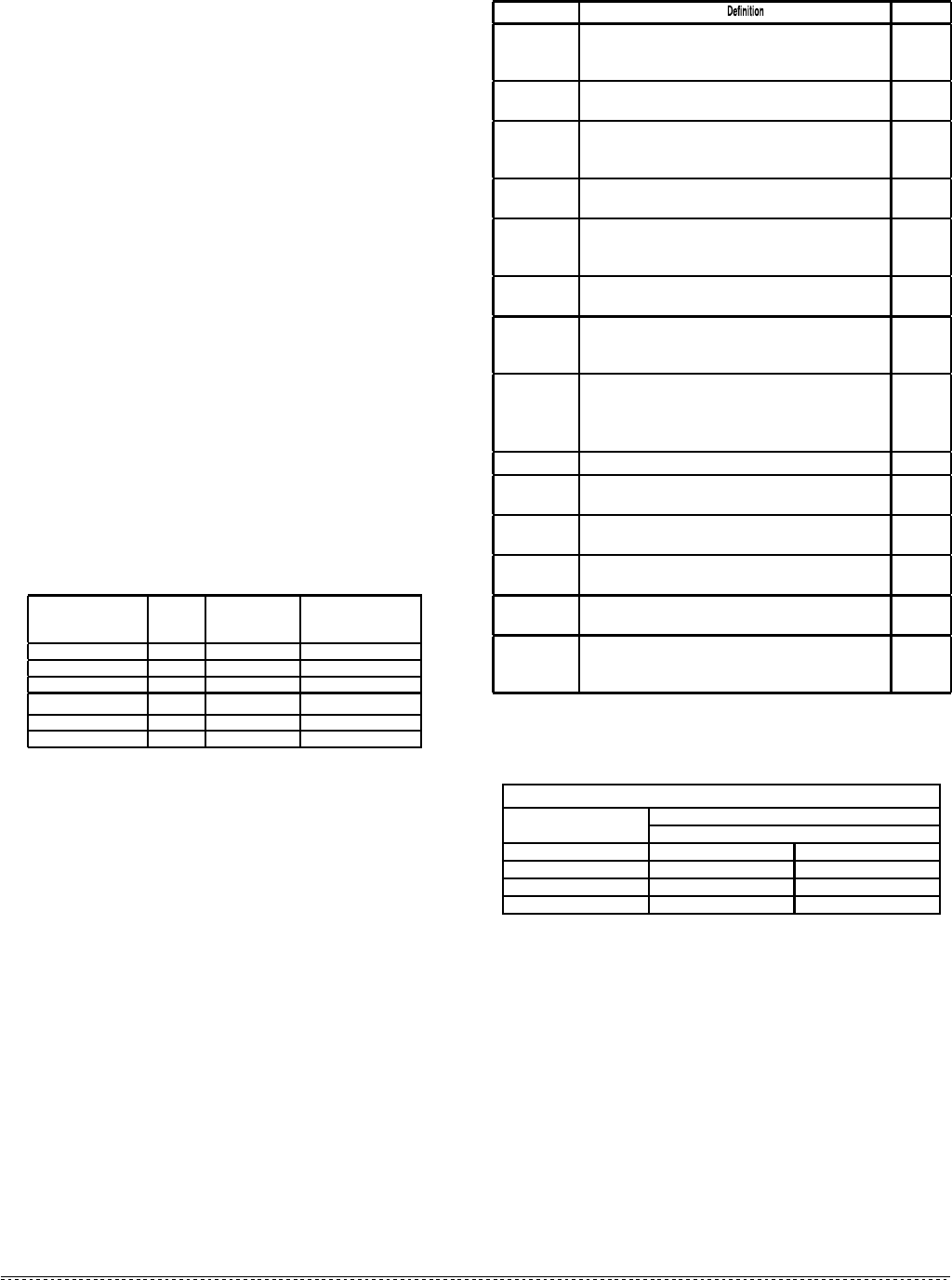

TIMING SPECIFICATIONS

(All times are in seconds, unless noted otherwise)

condition is corrected, before the last ignition attempt. Otherwise,

the control will go into system lockout. If the control has gone into

system lockout, it may be possible to reset the control by a

momentary power interruption of 10 seconds or longer.

Refer to SYSTEM LOCKOUT AND DIAGNOSTIC FEATURES.

Average

Calculated Duty

Cycle % Equals

Or less

than

Low to High

Stage Delay

Demand

0 38 12 minutes Light

38 50 10 minutes Light to Average

50 62 7 minutes Average

62 75 5 minutes Average to Heavy

75 88 3 minutes Heavy Light

88 100 1 minute Heavy

Event 50M51-843

Pre-purge Time The period of time intended to allow for the dissipation of any

unburned gas or residual products of combustion at the beginning

of a furnace operating cycle prior to initiating ignition

15

Igniter Warm-up

Time

The length of time allowed for the igniter to heat up prior to the

initiation of gas flow.

17

Trial for Ignition

Period (TFI)

The period of time between initiation of gas flow and the action to

shut off the gas flow in the event of failure to establish proof of the

supervised ignition source or the supervised main burner flame.

4

Ignition Activation

Period (IAP)

The period of time between energizing the main gas valve and

deactivation of the ignition means prior to the end of TFI

3

Retries The additional attempts within the same thermostat cycle for

ignition when the supervised main burner flame is not proven

within the first trial for ignition period.

2 times

Valve Sequence

period

Valve sequence period equals 4 seconds trial for ignition

period x (1 initial try + 2 retries) + 12 seconds.

12

Inter-purge The period of time intended to allow for the dissipation of any

unburned gas or residual products of combustion between the

failed trial for ignition and the retry period.

60

Post-purge Time

The period of time intended to allow for the dissipation of any

unburned gas or residual products of combustion at the end of a

furnace burner operating cycle. Post-purge begins at the loss

of flame sense.

15

Lock-Out Time ANSI standard rated module timing. 300

Heat Delay-To-

Fan-On

The period of time between proof of the supervised main burner

flame and the activation of the blower motor at Heat speed.

45

Heat Delay-To-

Fan-Off*

The period of time between the loss of a call for heat and the

deactivation of the blower motor at Heat speed.

90/120/

150/180

Cool Delay-To-

Fan-On

The period of time after a thermostat demand for cool before

energizing the circulator blower motor at Cool speed.

5

Cool Delay-To-

Fan-Off

The period of time between the loss of a call for cool and the

deactivation of the blower motor at Cool speed.

60

Automatic Reset

Time

After one (1) hour of internal or external lockout, the control will

automatically reset itself and go into an auto restart purge for 60

seconds.

60

minutes

*These times will vary depending on option switch position.

When using a single stage thermostat, second stage delay is

based on the setting of switch S1-1, S1-2 shown below.

OPTION SWITCHES S1-1 & S1-2 POSITIONS

*Factory default setting– two stage thermostat

2nd Stage delay for single stage thermostats

Delay Time:

On "S1" set switch #

1 2

Off* Off Off

10 min On Off

Auto min Off On

20 min On On

In a typical single stage cooling system (Y connection), a call

for cool is initiated by closing the thermostat contacts. This

energizes the compressor and the electronic air cleaner

(optional).

The circulator will be energized at cool speed after the COOL

delay-to-fan-on period. After the thermostat is satisfied, the

compressor is de-energized and the COOL delay-to-fan-off

period begins. After the COOL delay-to-fan-off period ends,

the circulator and the electronic air cleaner are de-energized.