Installation Guide

22

I&O manual

In unconfined spaces (see definition below) in buildings, infiltration may

be adequate to provide air for combustion ventilation and dilution of flue

gases. However, in buildings of tight construction (for example, weather

stripping, heavily insulated, caulked, vapor barrier, etc.), additional air

may need to be provided using the methods described in “An confined

space” section.

An

confined space

is an area with less than 50 cu . ft (1.42m

3

) per

1,000 Btu/hr (0.2928 kW) input rating for all of the appliances installed in

that area. The following must be considered to obtain proper air for

combustion and ventilation in confined spaces.

Air Supply Openings and Ducts

Combustion Air Source from Outdoors

1. Two permanent openings, one within 12 in (305 mm) of the top

and one within 12 in (305 mm) of bottom of the confined space,

Two permanent openings, shall communi cate directly or by means

of ducts with the outdoors, crawl spaces or attic spaces.

2. One permanent openings, commencing within 12 in (305 mm)of

the top of the enclosure shall be permitted where the equipment

has clearances of at least 1 in (25.4 mm) from the sides and back

and 6 in (152.4 mm) from the front of the appliance. The opening

shall communicate directly with the outdoors and shall have a min-

imum free area of:

a. 1 square in per 3000 Btu per hour (734 mm2/kW) of the total

input rating of all equipment located in the enclosure.

b. Not less than the sum of all vent connectors in the confined

space.

3. The duct shall be least the same

cross-sectional area as the free

area of the air supply inlet opening to which it connects.

4. The blocking effects of louvers, grilles and screens must be given

consideration in calculating free area. If the free area of a specific

louver aor grille is not known. Refer to Table ,“Estimated Free

Area” to estimated free area.

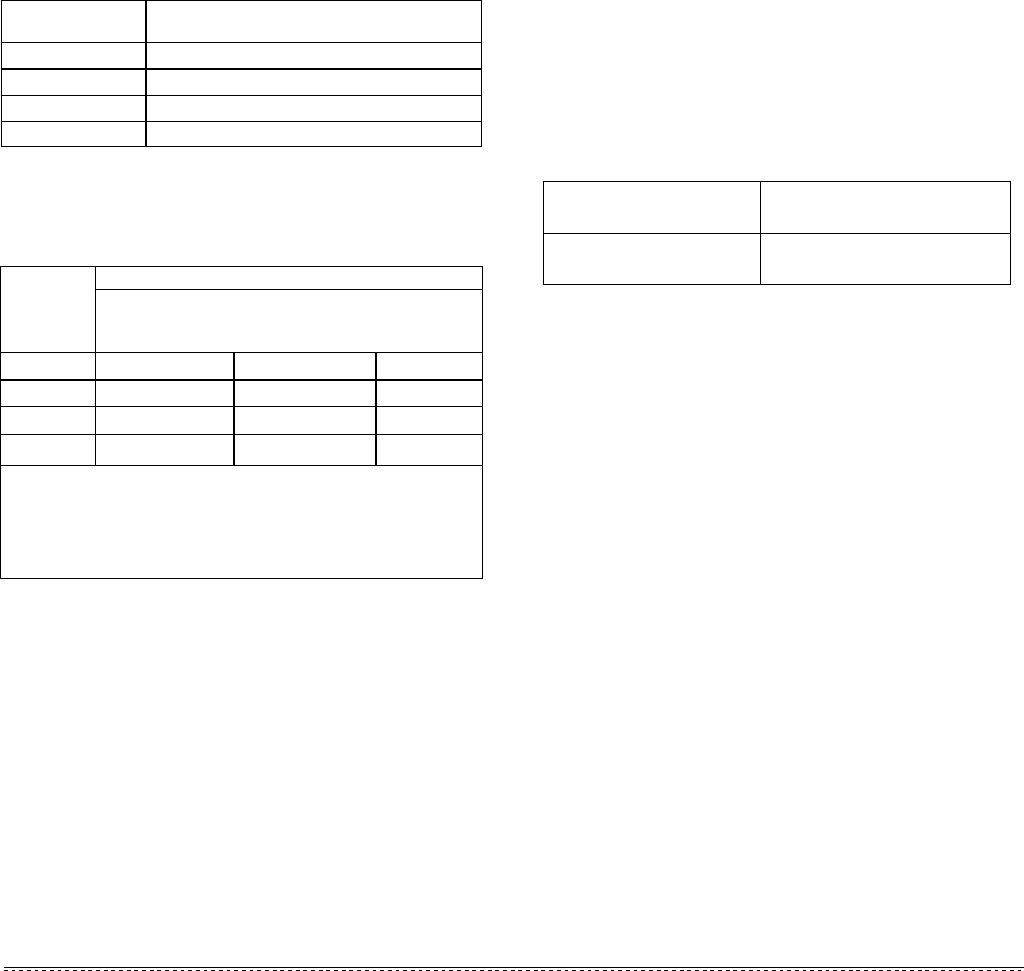

Table 10 : Estimated Free Area

Ventilated Combustion Air

The ventilated attic space or a crawl space from which the combustion

air is taken must comply with the requirements specified in “

Combustion

Air Source from Outdoors

” in this instruction or in Section 7.4, Air

for Combustion and Ventilation of the National Fuel Gas Code, ANSI

Z223.1 (latest edition). This type in stallation requires two properly sized

pipes. One brings combustion air from

a properly ventilated attic space

or crawl space and a second pipe that extends from the furnace vent

connection (top right of unit) to the exterior of the building.

Wood or Metal

Louvers or Grilles

Wood 20-25%

Metal 60-70%

Screens +

1/4” (0.635cm)

mesh or larger 100%

Table 9 : Minimum Free Area Required for Each Opening

b) All air from outdoors:

BTUH Input

Rating

Minimum Free Area Required for Each Opening

Horizontal Duct

(2,000 BTUH)

Vertical Duct or

Opening to Outside

(4,000 BTUH)

Round Duct

(4,000 BTUH)

60,000

30 in

2

(193 cm

2

)

2

(97 cm

2

)

5” (13 cm)

100,000

50 in

2

(322 cm

2

)

2

(161 cm

2

)

6” (15 cm)

80,000

40 in

2

(258 cm )

2

20 in

15 in

25 in

30 in

2

(129 cm

2

)

5” (13 cm)

120,000

60 in

2

(387 cm

2

)

2

(194 cm

2

)

7” (18 cm)

EXAMPLE: Determining Free Area.

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000

4,000) = 32.5 Sq. In. Vertical

Appliance 1 Appliance 2 Total Input

100,000 + 30,000 = (130,000

2,000) = 65 Sq. In. Horizontal

Table 8 : Minimum Area in Square Inch Required for Each Opening

a) All air from inside the building:

The confined space shall be provided with two permanent openings

communicating directly with an additional room(s) of sufficient volume

so that the combined volume of all spaces meets the criteria. The total

input of all gas utilization equipment installed in the combined space

shall be considered in making this determination. Each opening shall

have a minimum free area of 1 square inch per 1,000BTU per hour of

the total input rating of all gas utilization equipment in the confined sp-

ace. One opening shall be within 12 inches of the top and one within

12 inches of the bottom of the enclosure (See Table 8).

Equipment Located in Confined Spaces:

Vent and Supply (Outside) Air Safety Check Procedure

BTUH Input Rating

Minimum Free Area in Square Inch

Required for Each Opening

80 in (516 cm

2 2

) 100 in (645 cm

2

2

)

120 in (742 cm

2

2

)

80,000

60 in (387 cm

2 2

)

60,000

100,000

120,000

An opening may be used in lieu of a duct to provide to provide the

outside air supply to an appli ance unless otherwise permitted by

the authority having jurisdiction. The opening shall be located

within 12” (30.5 cm) horizontally from, the burner level of the appli-

ance.

The duct shall be either metal, or a material meeting the class 1

requirements of CAN4-S110 Standard for Air Ducts.

The duct shall be least the same cross-sectional area as the free

area of the air supply inlet opening to which it connects.

The duct shall terminate within 12 in (30.5 cm) above, and within

24 in (61 cm) horizontally from, the burner level of the appliance

having the largest input.

5. A square or rectangular shaped duct shall only be used when the

required free area of the supply opening is 9 in

2

(58.06 cm

2

) or

larger. When a square or rectangular duct is used, its small dimen-

sion shall not be less than 3 in (7.6 cm).

6. An air inlet supply from outdoors shall be equipped with a means

to prevent the direct entry of rain and wind. Such means shall not

reduce the required free area of the air supply opening.

7. An air supply inlet opening from the outdoors shall be located not

less than 12” (30.5 cm) above the outside grade level.

4.

3.

2.

1.

For Category I furnaces, vent installations shall be in accordance

with Parts 7 and 11 of the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and or Section 7 and Appendix B of the CAS B

149.1, Natural Gas and Propane Installation Codes, the local

building codes, furnace and vent manufacture’s instructions.

Multi-story or common venting systems are permitted and must be

installed in accordance with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and / or the CSA B 149.1, Natural Gas and

Propane Installation Codes, and the manufacture’s instructions.

Vent connectors serving Category I furnaces shall not be connected

into any portion of mechanical draft systems operating under positive

pressure.