User Manual

Set-up for operation Water cooled systems

M

20.1

REV.2-04/15

12/06/03 M20-R-HO2-GB

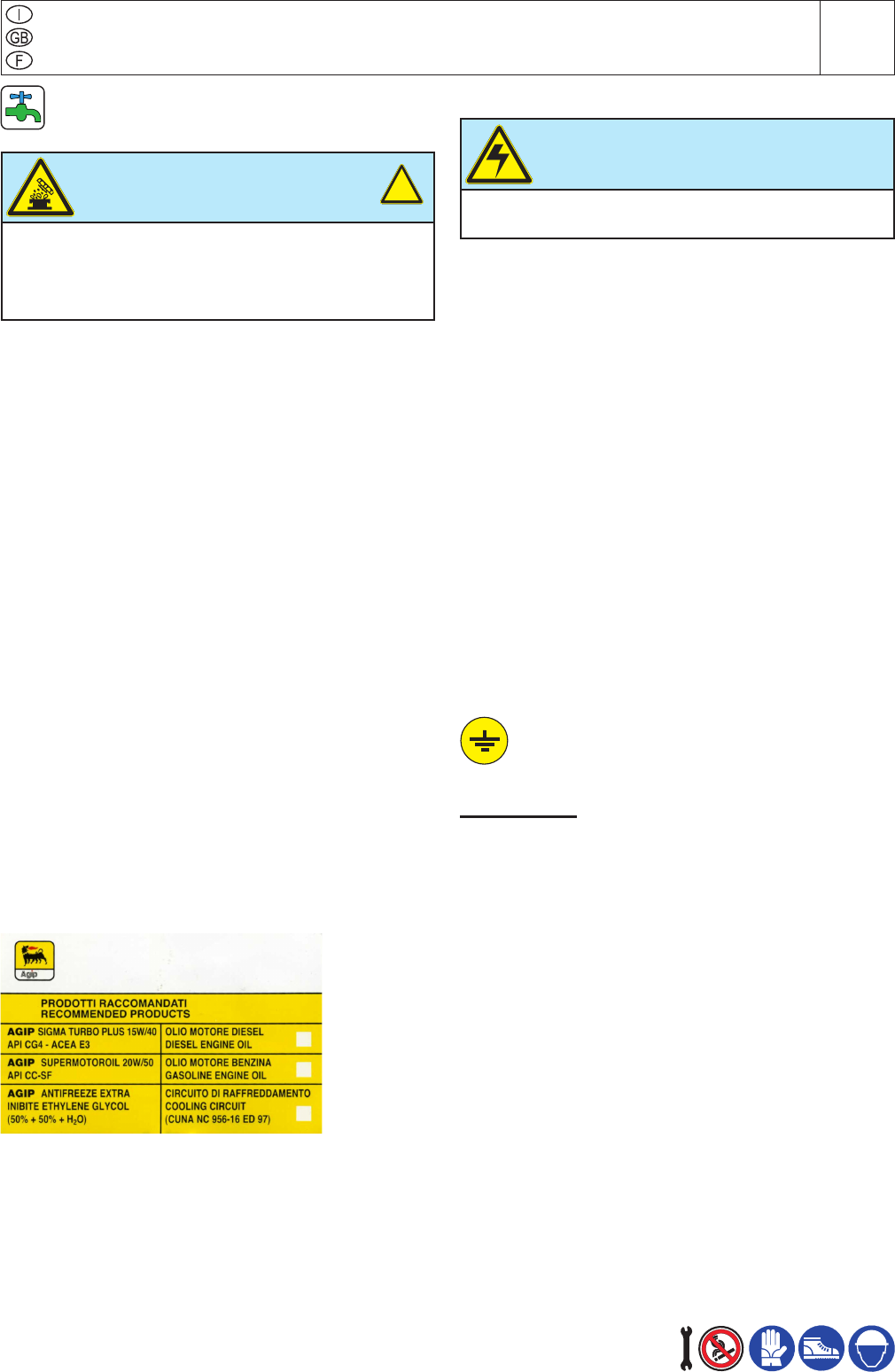

Remove the tap and pour the liquid coolant into the

radiator; the quantity and composition of the liquid

coolant are indicated in the motor operating manual.

Replace the tap, ensuring it is perfectly closed.

After relling operations, allow the motor to run for

a brief time and check the level, as it may have di-

minished due to air bubbles present in the cooling

circuit; restore the level with water.

To replace the liquid coolant, follow the operations

described in the motor operating manual.

:

The engine cooling system is originally lled with

coolant type:

During the engine life it is strongly recommended

to use the same coolant type. This is because a

coolant change would require a careful cleaning of

the cooling system, which is not an easy job. A lack

in tacking these precautions would result in the mix

of different additives used in different coolants which

would originate gelatinous substances capable of

obstructing the cooling system.

Do not remove the radiator tap with the motor in

operation or still hot, as the liquid coolant may

spurt out and cause serious burns. Remove the

tap very carefully.

A qualied electrician should carry out electrical con-

nections according to the norms in force.

!

The electrical connection to the User system is a very

important operation: safety and good operation of the

genset and User system depend on a correct electrical

connection.

Before supplying User system always check:

• that wires connecting gen-set to the user plant are

suitable to the supplied voltage and are in accordan-

ce to the applicable rules;

• wire type, section and length have been calculated

considering environment conditions and in force

norms;

• ground is functioning correctly: earth fault relay devi-

ce works only if this connection is operating;

• that direction of the phases corresponds to the user

plant phase rotation, and none of the phases has

been accidentally connected to neutral.

The grounding connection to an earthed installation

for all models equipped with a diffe-

rential switch (circuit breaker). In these groups the

generator star point is generally connected to the

machine’s earthing; by employing the TN or TT di-

stribution system, the differential switch guarantees

protection against indirect contacts.

In the case of powering complex installations re-

quiring or employing additional electrical protection

devices, the coordination between the protection

devices must be veried.

For the grounding connection, use the terminal (12);

comply to local and/or current regulations in force

for electrical installations and safety.