User`s manual

13 - 6 13 - 6

MELSEC-Q

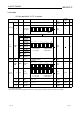

13 AUTO TUNING

Specified position Symbol Name Recommended range

*1

Unit Data format

Standard

value

Store

D2

+52

+53

P Gain 0 to 999999

Real

number

1.0 S/U

+54

+55

I

Integral

constant

0 to 999999 s

Real

number

10.0 S/U

+56

+57

D

Derivative

constant

0 to 999999 s

Real

number

0.0 S/U

+70

+71

AT1

STEP

MV

Step

manipulated

value for AT1

-100 to 100 %

Real

number

0.0 U

+72

+73

AT1ST

Sampling

cycle for AT1

0 to 999999 Note that

T

AT1ST

32767

s

Real

number

1.0 U

Loop tag

memory

*2

+74

+75

AT1

TOUT1

Time-out time

for AT1

0 to 999999 Note that

T

AT1TOUT1

3276

7

s

Real

number

100.0 U

+76

+77

AT1

TOUT2

After

maximum

slope time-out

time for AT1

0 to 999999 Note that

T

AT1TOUT2

3276

7

s

Real

number

10.0 U

D3

+0

Local

work

memory

*3

+21

System area Used by the system as a work area. S

*1: The data of the item(s) where the values within the recommended range are given in the parentheses are stored by the system.

Users cannot set the data.

*2: The loop tag memory and loop tag past value memory occupy a total of 128 words. (Refer to Section 3.3.1 for details.)

*3: The applications of the loop tag past value memory are indicated below.

Specified position contents

S3

+0 Sampling cycle counter initial preset flag

+1 Sampling cycle counter

+2 Time-out time counter initial preset flag

+3 Time-out time counter

+4 After maximum slope time-out time counter initial preset flag

+5 After maximum slope time-out time counter

+6 Step manipulated value preset flag

+7 Counter from auto tuning start

+8

+9

Auto tuning start-time PV0

+10

+11

PV

n-1

(Last process value)

+12

+13

Maximum slope value

+14

+15

Maximum slope-time counter

+16

+17

Maximum slope-time PV

+18

+19

R (Response speed)

+20

+21

L (Equivalent dead time)

When control is to be started from the initial status, the data must be cleared with the sequence program.

(2) Execution cycle ( T)

Set the execution cycle in SD1500 and SD1501 as a real number.